Artificially synthesized polymer fracturing fluid with molecular weight of 500,000 to 10,000,000

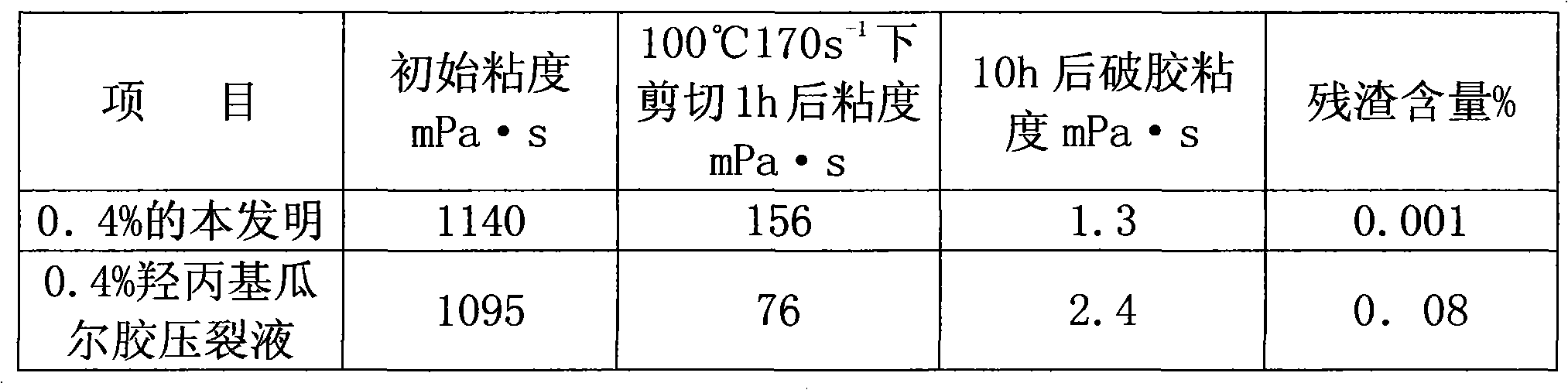

A synthetic polymer and artificial synthesis technology, which is applied in the directions of drilling compositions, chemical instruments and methods, etc., can solve the problem of poor temperature resistance, large flow conductivity of filling layers and formation damage, and poor shear resistance and salt resistance. and other problems, to achieve good temperature resistance and eliminate the effect of macromolecular chain residues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0011] Embodiment 1, the volume that needs to be made into the present invention is 150m 3 :

[0012] Synthetic polymer: 675 kg, crosslinker: 375 kg, clay stabilizer 825 kg, surfactant: 450 kg, oxidant: 7.5 kg and water: 148270 kg.

[0013] In the above formula, the synthetic polymer is: a copolymer of acrylamide-based monomer and vinyl monomer with a molecular weight of 5 million; the crosslinking agent is: organic chromium and formaldehyde mixture (organic chromium is chromate, ethylene glycol, Compound of acetic acid and lactic acid); clay stabilizer: KCl; surfactant: 0-20 and fluorocarbon; oxidant: ammonium persulfate.

Embodiment 2

[0014] Embodiment 2, the volume that needs to be made into the present invention is 100m 3 :

[0015] Water 97570kg, synthetic polymer 1000kg, crosslinking agent 800kg, clay stabilizer 1000kg, surfactant 400kg, oxidant 30kg.

[0016] In the above formula, the synthetic polymer is: a homopolymer of acrylamide-based monomer with a molecular weight of 500,000; the crosslinking agent is: a mixture of organic chromium and organic aluminum; the clay stabilizer is: NH4Cl; the surfactant is: OP- 10; The oxidant is: Periodic acid. The organoaluminum mixture in the crosslinking agent is a compound of chromium salt, aluminum salt, glycerol, citric acid and glyoxal.

Embodiment 3

[0017] Embodiment 3, the volume that needs to be made into the present invention is 280m 3 :

[0018] 274,120 kg of water, 84 kg of synthetic polymer, 560 kg of cross-linking agent, 2,800 kg of clay stabilizer, 2,240 kg of surfactant, and 4.2 kg of oxidant.

[0019] The synthetic polymer in the above formula is: a copolymer of acrylamide-based monomer, vinyl monomer and hydrophobic monomer with a molecular weight of 10 million; the cross-linking agent is: a mixture of formaldehyde, glyoxal and phenolic; the clay stabilizer is : KBr and tetramethylammonium chloride; surfactant: NP-100 and fluorocarbon; oxidant: ammonium persulfate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com