Catalytic cracking method with maximisation of diesel bases

A base oil, catalytic cracking technology, used in catalytic cracking, chemical instruments and methods, catalyst regeneration/reactivation, etc., can solve the problems of reduced catalyst activity, low specific surface area, low yield, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

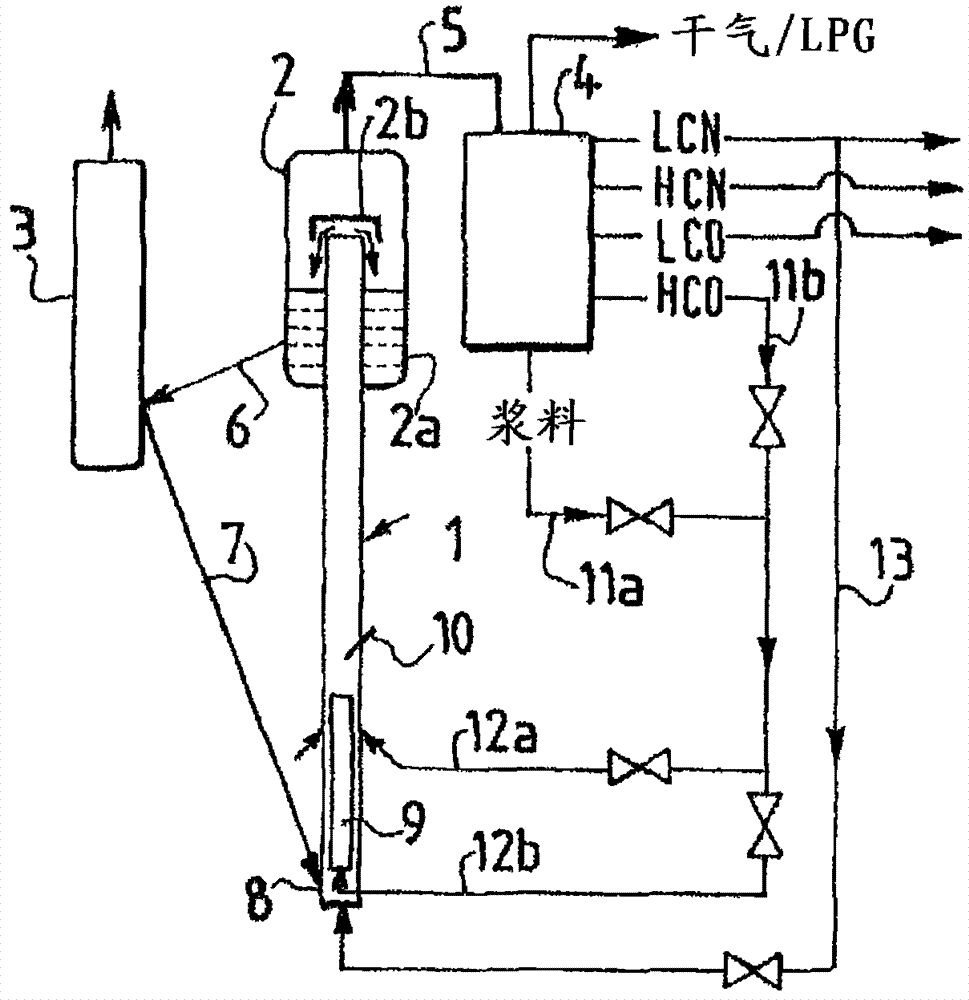

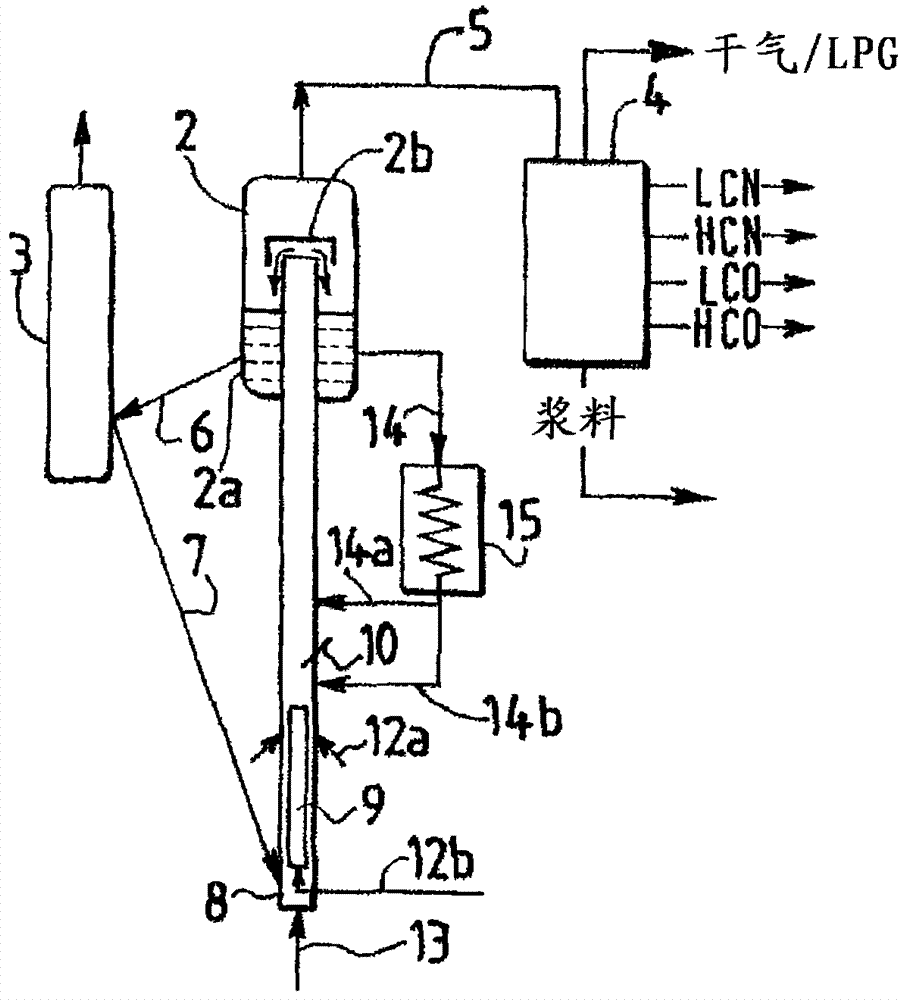

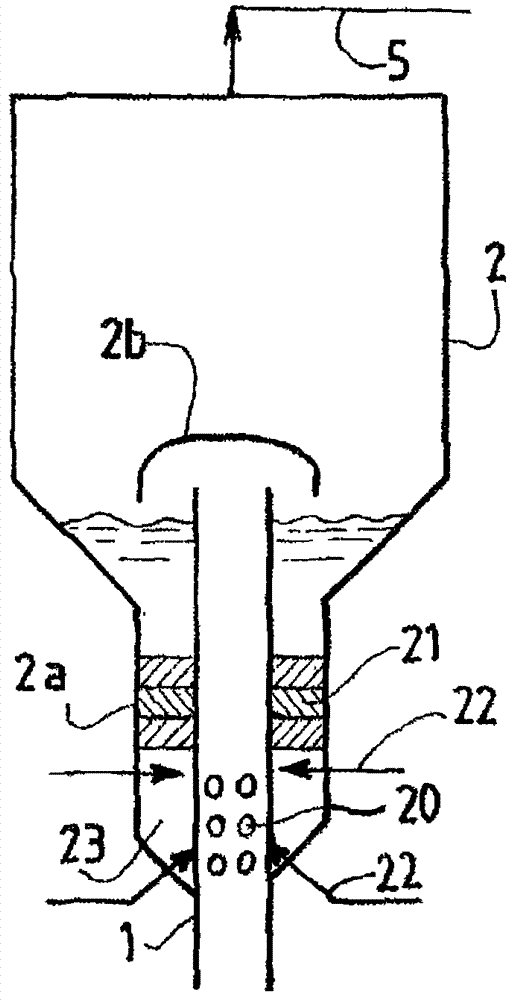

Method used

Image

Examples

Embodiment 1

[0072] This example shows the results obtained between a conventional catalytic cracking unit operating in a gasoline-maximizing mode and a catalytic cracking or FCC unit modified according to the invention with one or two upflow reactors operating in a distillate-maximizing mode. Comparing results.

[0073] This corresponds to a modification of an existing FCC plant that processes pre-hydrotreated vacuum distillate feedstock and uses a common acidic catalyst (product from Albemarle) where the ratio of micropore specific surface to mesopore specific surface is equal to two.

[0074] To increase distillate production while minimizing light gasoline production, the operating conditions of the FCC and the cutting point of the effluent produced in the primary fractionation were varied. The catalyst remains the same regardless of equipment configuration and operating conditions. Two operations of a device having a configuration (X1 and X2) corresponding to the features of the inve...

Embodiment 2

[0086] Based on the results obtained on the test plant, this example shows different sets of yields that can be obtained for a feedstock consisting exclusively of atmospheric residue at operating conditions and the use of catalyst recycled from the separator and the recycle of the unconverted fraction as function obtained.

[0087] The catalyst is a conventional catalyst used for the production of gasoline from heavy atmospheric residue type feedstock (the ratio of micropore specific surface to mesopore specific surface is equal to 1, total surface area = 110m 2 / g, Ni = 3000 ppm by weight and V = 5000 ppm by weight). The raw material is atmospheric residual oil with a boiling point of 330-730°C and a density of 928.9kg / m 3 , Conradson (Comradson) carbon residue is 3.9% by weight.

[0088] In this example, Example 1 corresponds to the gasoline operating mode, which favors the production of light and heavy gasoline and liquefied gas (LPG). This is the reference ratio for this...

Embodiment 3

[0096] This example illustrates the advantages of the present invention using conventional cracking catalysts, which are beneficial for gasoline production due to the high microporous (even zeolite) specific surface, which is characterized in Compared with shaped catalysts (commercially known as BCA (bottom cracking additive)), the ratio of micropore specific surface to mesopore specific surface is usually above 2, which is beneficial to the production of LCO under the same cracking conditions claimed in the present invention But it is not good for the slurry.

[0097] The operating conditions (TRX or temperature and C / O) are given in Table IV below. As previously described in Example 2, 3 runs were performed using a zeolite catalyst and 2 additional runs used a BCA catalyst known to preferentially form LCO-type distillates.

[0098] E1 corresponds to plant operation in gasoline mode on a zeolite catalyst.

[0099] D1 corresponds to plant operation in distillate mode on zeol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com