Recording/reproducing method in read-only holographic recording medium, and read-only holographic recording medium

A holographic recording medium and recording technology, applied in optical recording/reproducing/erasing methods, recording information storage, recording/reproducing/erasing using optical interference patterns, etc. The effect of increased multiplicity, high S/N and high transmission rate, and simple medium structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

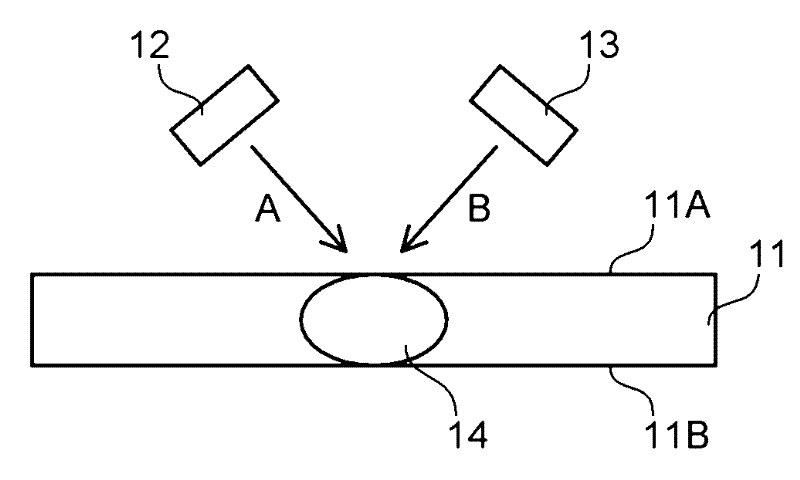

Method used

Image

Examples

experiment example 1

[0109] As a material for the above-mentioned hologram recording medium, a photopolymer composition having the following composition was prepared in a nitrogen atmosphere.

[0110] Hexamethylene diisocyanate (manufactured by Tokyo Chemical Industry Co., Ltd.) (refractive index n D =1.453) 30.8 parts by weight; polyoxypropylene triol (polyether triol, manufactured by (Co., Ltd.) ADEKA, G-400, average molecular weight 409) (refractive index n D =1.469) 48.1 parts by weight; acrylic acid derivatives of 9,9'-bis(4-hydroxyphenyl)fluorene diglycidyl ether (9 , 9-Bis(4-hydroxyphenyl)fluorine containing acrylic acid, manufactured by Nippon Steel Chemical Co., Ltd., ASF-400) (refractive index n D = 1.616) 4.0 parts by weight; dibutyltin dilaurate (manufactured by Shukyo Chemical Industry Co., Ltd.) 0.03 parts by weight; bis(η5-2,4-cyclopentadiene-l-y1)-bis(2,6 -Difluoro-3-(1H-pyrrole-1-yl)-phenyl)titanium (bis(η5-2,4-cyclopentadien-l-y1)-bis(2,6-difluoro-3-(1H-pyrol -1-yl)–phenyl)tit...

experiment example 2

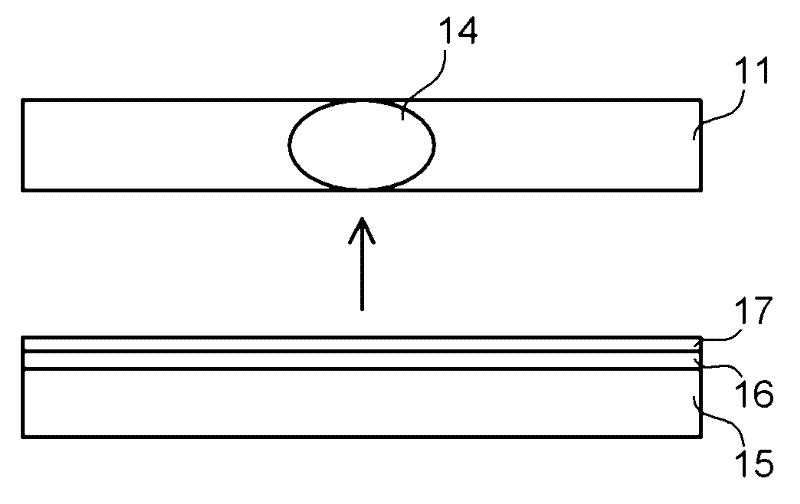

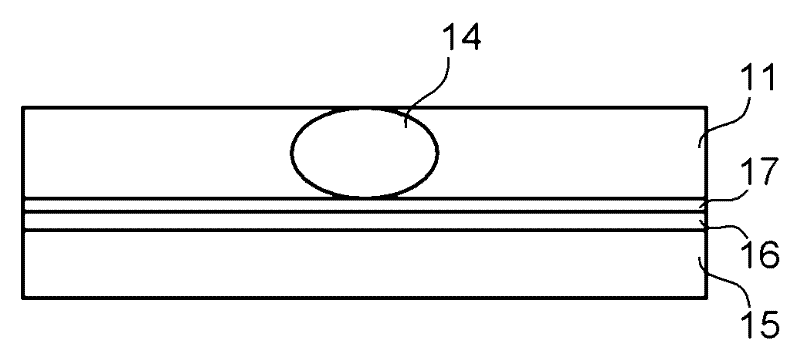

[0126] The material of the hologram recording medium was prepared in the same manner as in Experimental Example 1. Next, the photopolymer composition is placed under a nitrogen atmosphere at a refractive index n D About 1.523 0.5 mm thick glass substrates (B270) were injected so as to have a thickness of 700 μm, and after standing overnight, they were heat-treated at 60° C. for 5 hours to obtain a hologram recording medium.

[0127] Next, on the back surface of the glass substrate with a thickness of 0.2 mm, a black adhesive tape was attached for the purpose of anti-reflection so as not to allow air bubbles to enter. At this time, when light with a wavelength of 532 nm was incident from the recording material side, the reflectance at the interface between the glass substrate and the adhesive tape was about 1%. In addition, since the above-mentioned adhesive tape is attached for the purpose of preventing reflection, the same effect can be obtained by applying a light-absorbing...

experiment example 3

[0132] The material of the holographic recording medium was prepared in the same manner as in Experimental Example 1-1. Next, the photopolymer composition, under nitrogen atmosphere, at the refractive index n D 1.487 and a thickness of 0.5mm and 0.2mm glass substrates (OHARA S-FSL5) were injected so as to have a thickness of 700 μm, and after standing overnight, heat treatment at 60° C. for 5 hours to obtain a holographic recording medium. At this time, the substrate was installed so that the antireflection film faced outward. At this time, when light with a wavelength of 532 nm was incident from the recording material side, the reflectance on the outer surface (surface on which the antireflection film was formed) of the 0.2 mm glass substrate was about 0.5%.

[0133] Next, in the same manner as in Experimental Example 1, 520 multiple recordings were performed. At this time, hologram recording was performed by making recording light incident from the side of the 0.5 mm thick...

PUM

| Property | Measurement | Unit |

|---|---|---|

| reflectivity | aaaaa | aaaaa |

| reflectivity | aaaaa | aaaaa |

| reflectivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com