Aluminate luminescent material and preparation method thereof

A technology of luminescent materials and aluminates, which is applied in the direction of luminescent materials, chemical instruments and methods, and can solve the problems of low energy conversion efficiency of rare earth ions and affecting luminous efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] see Figure 7 , illustrating the process flow of the aluminate luminescent material preparation method of the embodiment of the present invention, the preparation method includes the following steps:

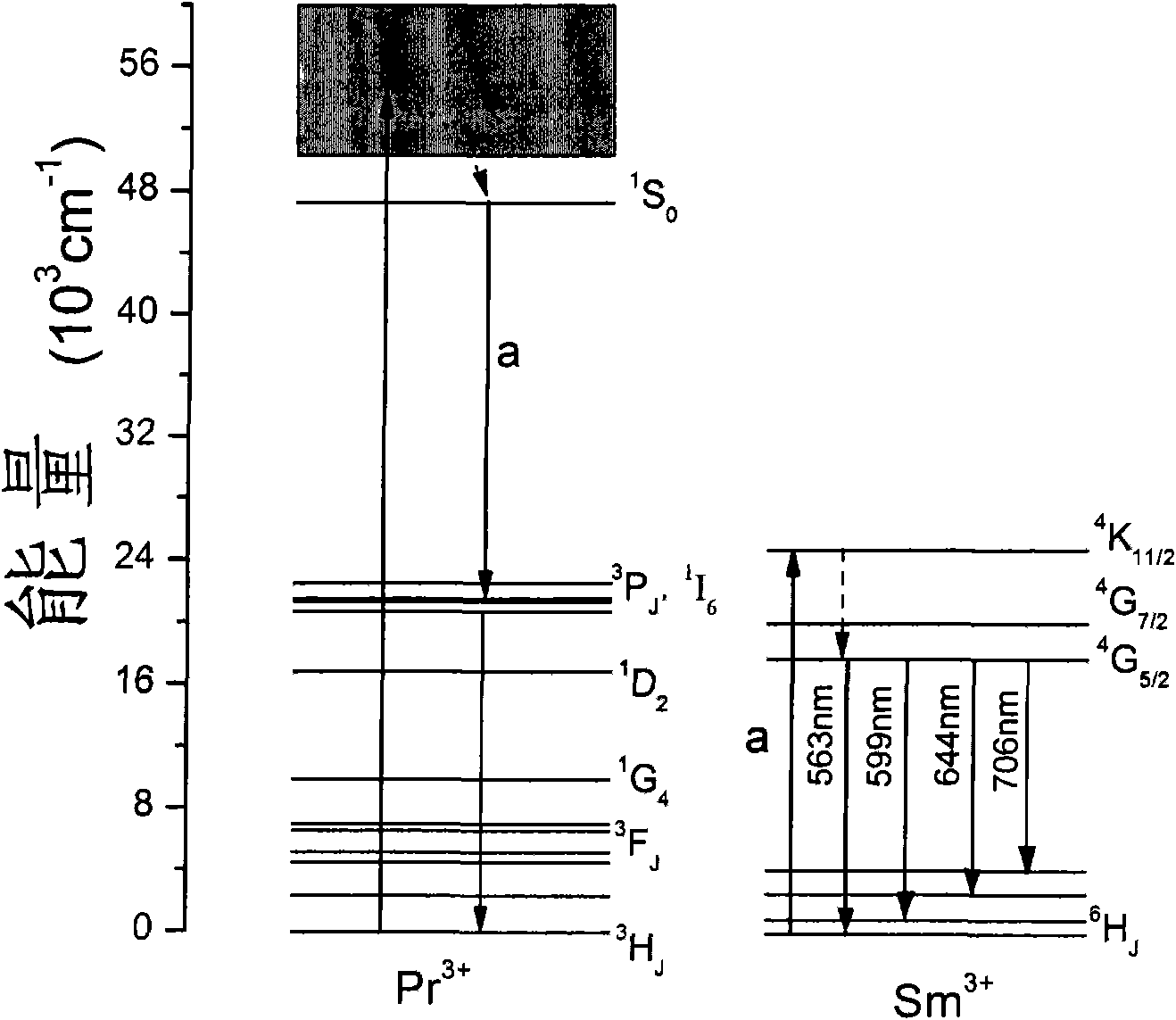

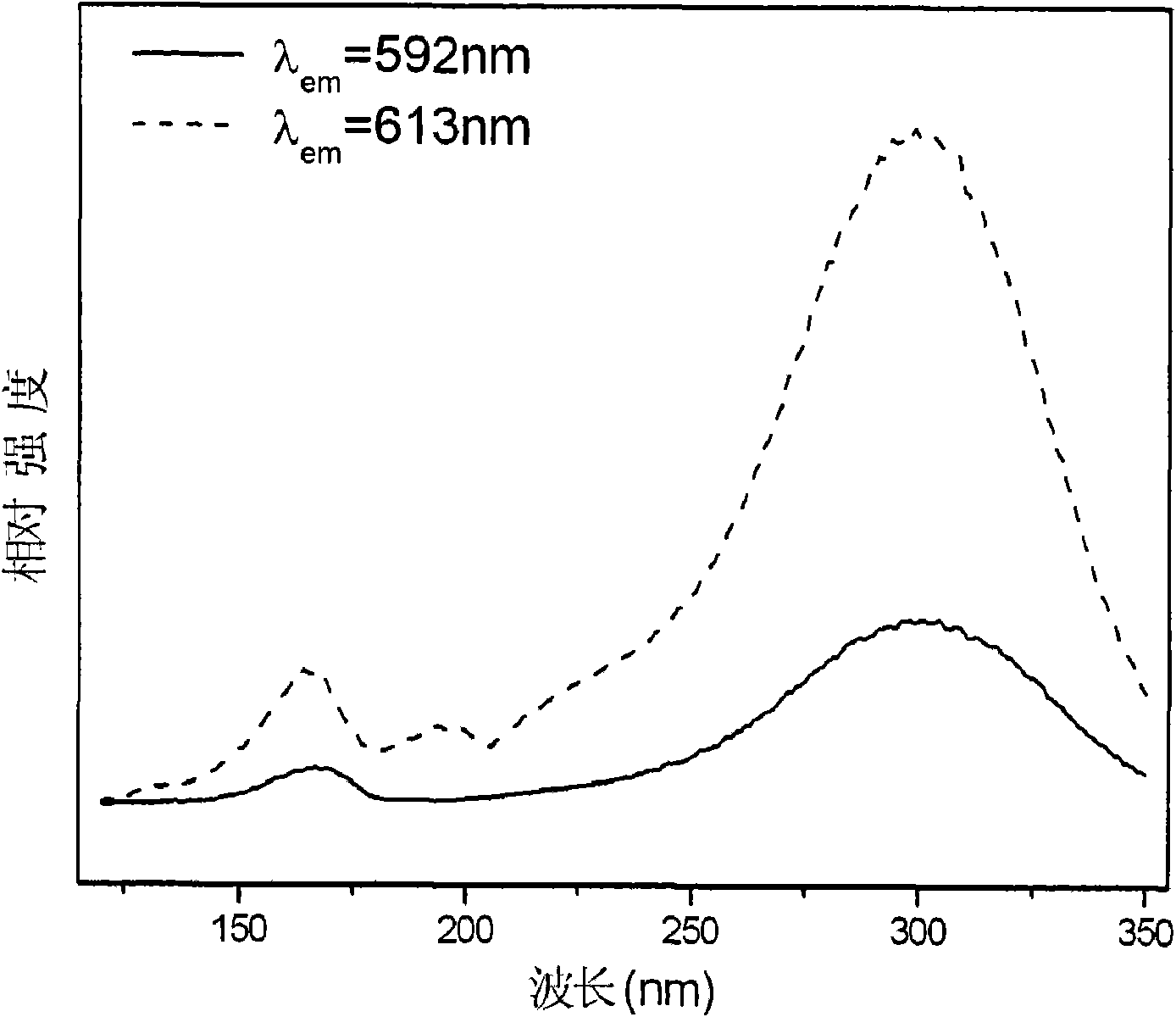

[0032] S01: Select the source compound of alkaline earth metal ion, the source compound of aluminum ion and the source compound of Re ion and praseodymium ion according to the stoichiometric ratio, and the stoichiometric ratio is according to the structural formula M 1-x-y PR x Eu y Al 12 o 19 The molar ratio of the corresponding elements in, wherein, M is an alkaline earth metal element, Re is Eu, Sm or a combination of both, x=0.005-0.1, y=0.01-0.2;

[0033] S02: mix each source compound evenly;

[0034] S03: pre-sintering or pre-burning the mixture, and then cooling;

[0035] S04: taking out the cooled product and grinding it, then calcining the ground product, and obtaining the aluminate luminescent material after cooling.

[0036] In step S01, the source compo...

Embodiment 1

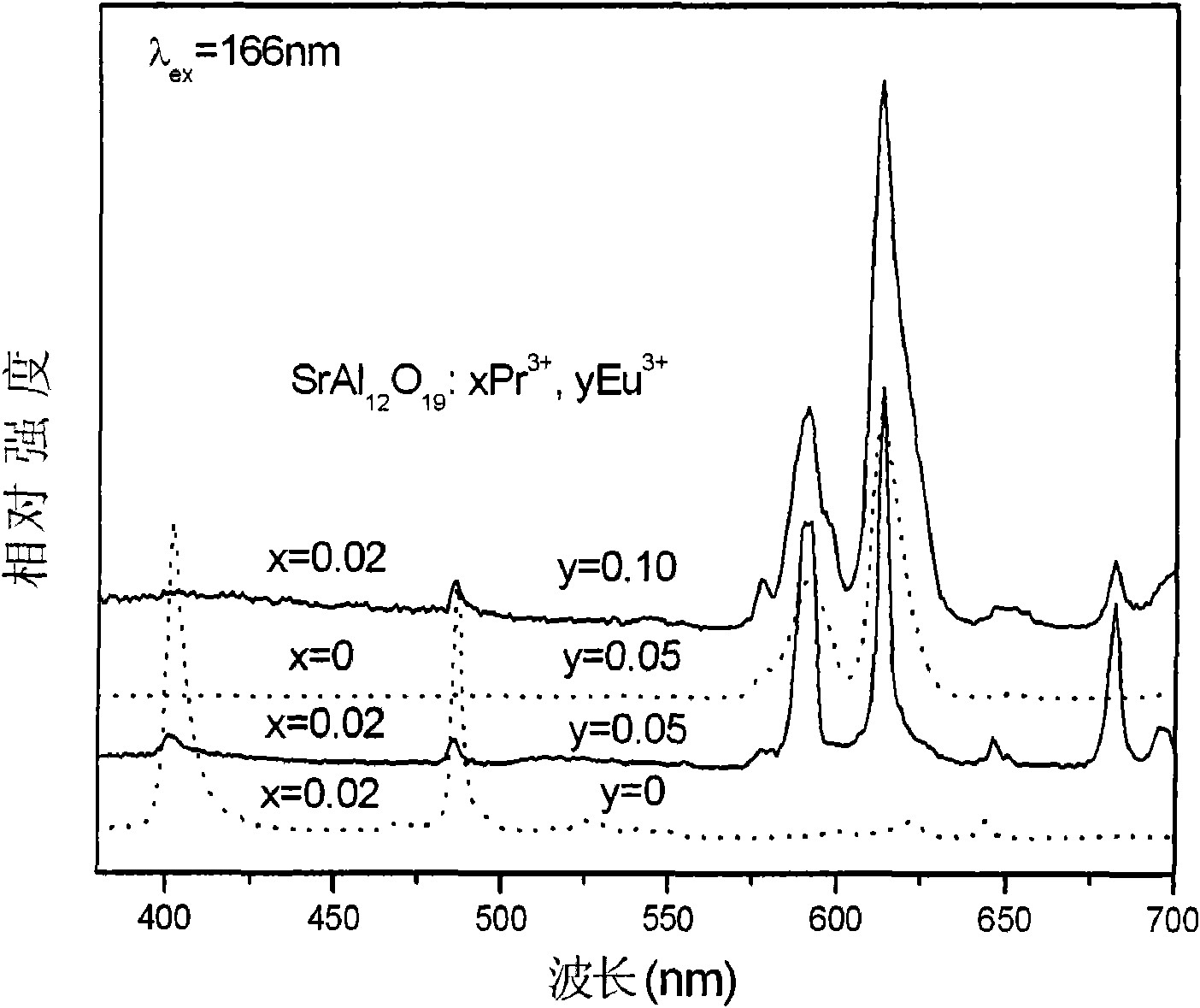

[0050] Weigh strontium carbonate SrCO 3 1.3877g, praseodymium oxide Pr 6 o 11 0.0170g, europium oxide Eu 2 o 3 0.0880g, aluminum oxide Al 2 o 3 6.1176g and boric acid H 3 BO 3 0.0618g (10%) was placed in an agate mortar and thoroughly ground, then placed in a corundum crucible and pre-fired at 500°C for 1h, then cooled to room temperature, taken out and fully ground again. Finally, it was calcined at 1500°C for 5h, cooled, taken out and ground to obtain powdery Sr 0.94 PR 0.01 Eu 0.05 Al 12 o 19 Red fluorescent aluminate luminescent material.

Embodiment 2

[0052] Weigh strontium carbonate SrCO 3 0.6495g, praseodymium oxide Pr 6 o 11 0.0170g, europium oxide Eu 2 o 3 0.0880g, magnesium oxide MgO 0.0240g, aluminum oxide Al 2 o 3 3.0282g and boric acid H 3 BO 3 0.0309g was placed in an agate mortar and thoroughly ground, then put into a corundum crucible and pre-fired at 500°C for 1h, then cooled to room temperature, taken out and fully ground again. Finally, it was calcined at 1500°C for 5 hours, cooled, taken out and ground to obtain the powdery red fluorescent aluminate luminescent material Sr 0.88 PR 0.02 Eu 0.10 Mg 0.12 Al 11.88 o 19 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com