Compound corrosion inhibitor for corrosion medium and preparation method thereof

A technology of corrosion medium and corrosion inhibitor, applied in the field of compound corrosion inhibitor and its preparation, can solve the problems of low toxicity of tungstate, low corrosion inhibition efficiency, low environmental pollution, etc. Simple, easy to compound effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0047] The present invention proposes a preparation method of a composite corrosion inhibitor suitable for corrosive media, which specifically includes the following steps:

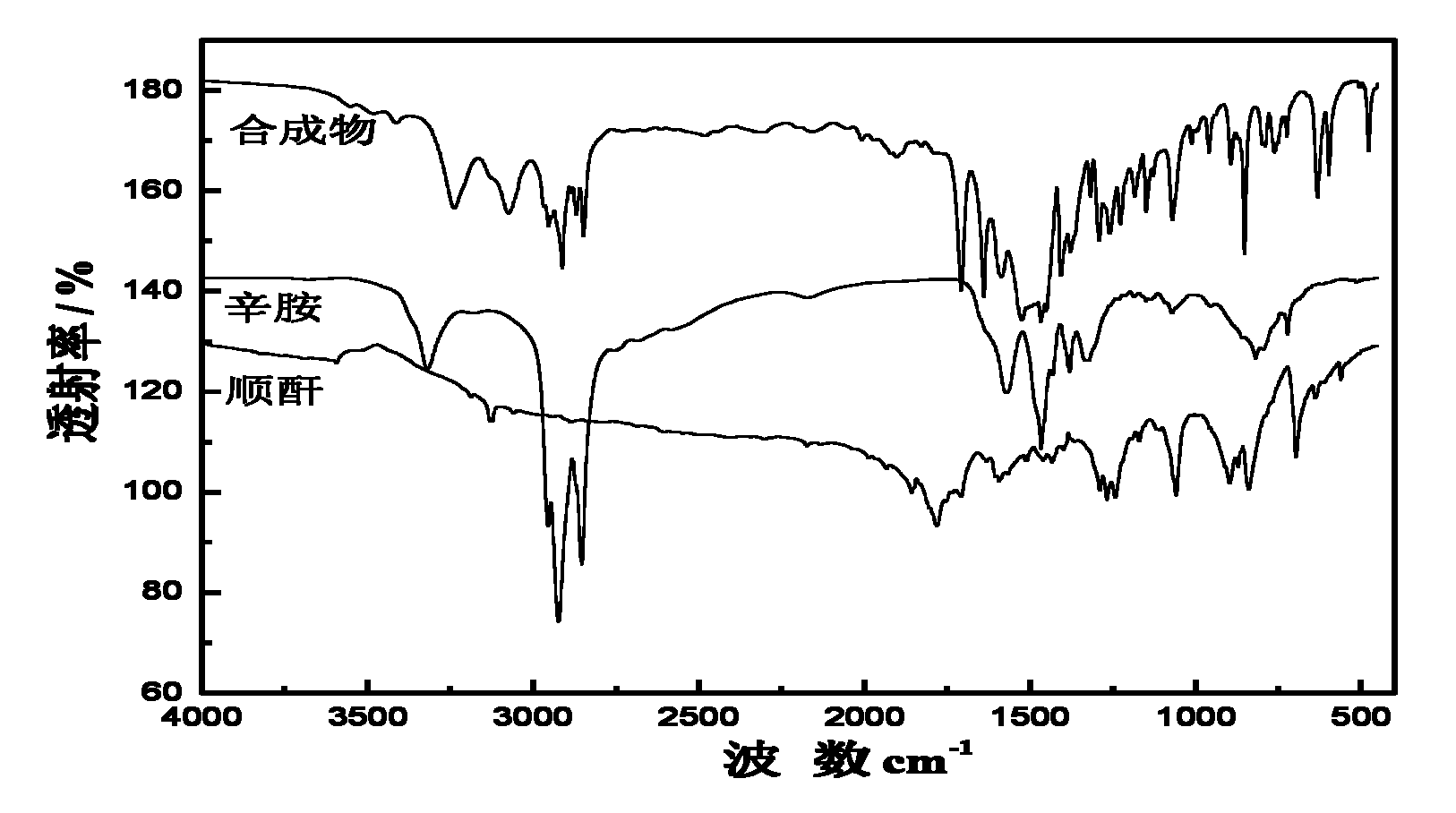

[0048] Step 1: Preparation of maleic anhydride octylamine corrosion inhibitor.

[0049] Dissolve maleic anhydride (maleic anhydride for short) and octylamine in a carbon tetrachloride organic solvent according to a molar ratio of 1:1 to 1:1.5 to obtain a maleic anhydride-carbon tetrachloride solution and octylamine-carbon tetrachloride solution. Under the condition of stirring, add the octylamine-carbon tetrachloride solution dropwise into the maleic anhydride-carbon tetrachloride solution, stir and react at 0-15°C for 3-4 hours, then let stand for 10- After 20 hours, the precipitate was filtered out with suction, washed with carbon tetrachloride organic solvent and dried to obtain a white solid powder that is a maleic anhydride octylamine corrosion inhibitor. The reaction equation is:

[0050]

[00...

Embodiment 1

[0060] The present invention proposes a method for preparing a composite corrosion inhibitor suitable for corrosive media, which specifically includes the following steps:

[0061] Step 1: Preparation of maleic anhydride octylamine corrosion inhibitor.

[0062] According to the ratio of 1:1, maleic anhydride 9.8g and octylamine 12.9g were dissolved in carbon tetrachloride organic solvent respectively to obtain maleic anhydride-carbon tetrachloride solution and octylamine-tetrachloride Carbon chloride solution. Under the condition of stirring, add the octylamine-carbon tetrachloride solution dropwise to the maleic anhydride-carbon tetrachloride solution, stir and react at 0°C for 3 hours, let it stand for 10 hours, and filter out The precipitate was washed with carbon tetrachloride organic solvent and dried to obtain a white solid powder that is maleic anhydride octylamine corrosion inhibitor.

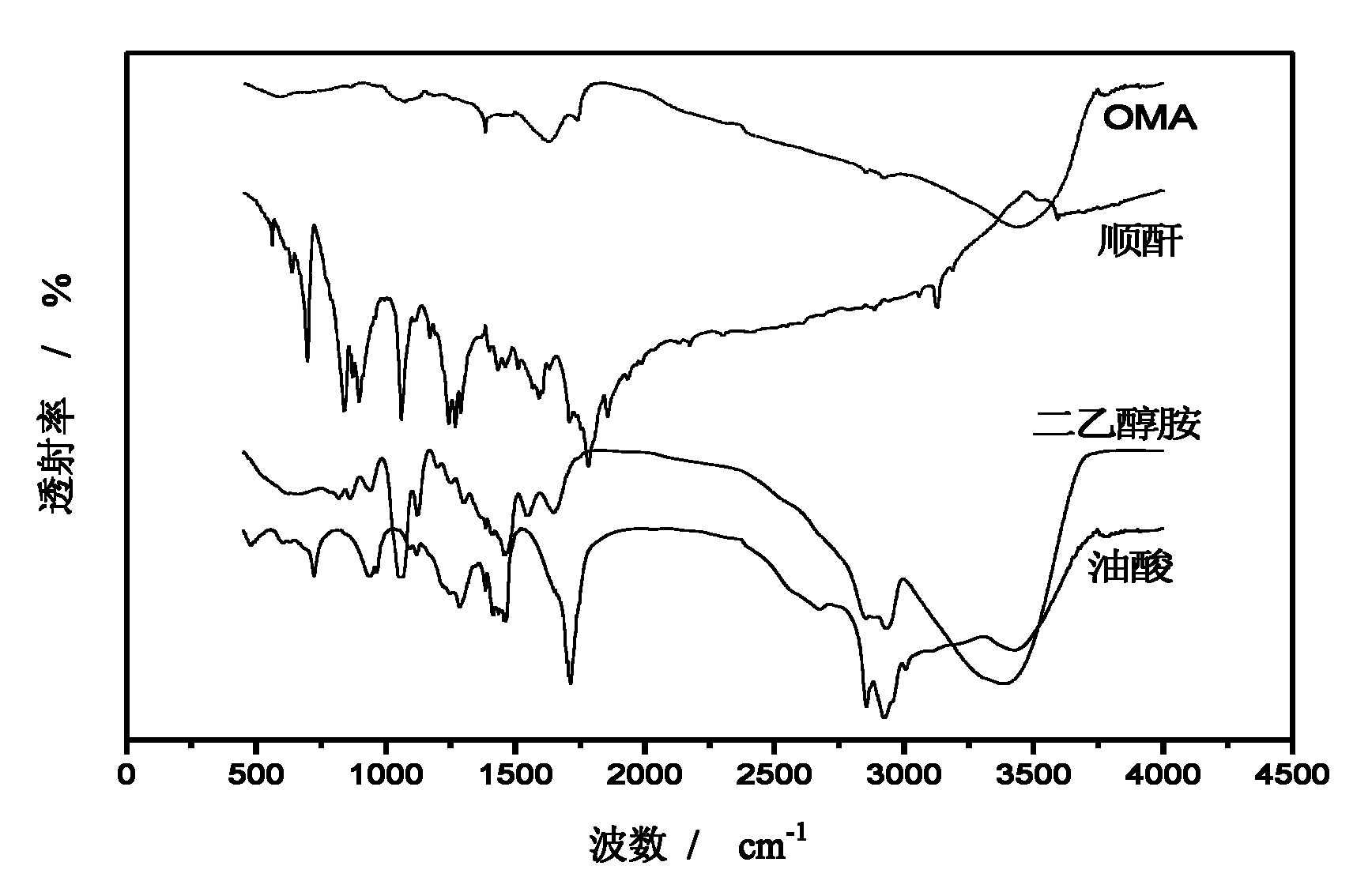

[0063] Step 2: Preparation of oleic acid amide corrosion inhibitor.

[0064] Hea...

Embodiment 2

[0073] Step 1: Preparation of maleic anhydride octylamine corrosion inhibitor.

[0074]Dissolve maleic anhydride and octylamine in the carbon tetrachloride organic solvent according to the molar ratio of 1: 1.5 to obtain maleic anhydride-carbon tetrachloride solution and octylamine-carbon tetrachloride solution . Under the condition of stirring, add the octylamine-carbon tetrachloride solution dropwise to the maleic anhydride-carbon tetrachloride solution, stir and react at 15°C for 4 hours, let it stand for 20 hours, and filter out The precipitate was washed with carbon tetrachloride organic solvent and dried to obtain a white solid powder that is maleic anhydride octylamine corrosion inhibitor.

[0075] Step 2: Preparation of oleic acid amide corrosion inhibitor.

[0076] Heat oleic acid to 150°C under the protection of nitrogen, add maleic anhydride in an equimolar amount to oleic acid under stirring conditions, then add KOH catalyst, and react at 190°C for 4 hours. The a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com