Trench metal oxide semiconductor field effect transistor and manufacturing method thereof

A technology of oxide semiconductors and field effect transistors, which is applied in the field of trench metal oxide semiconductor field effect transistors and its manufacturing, can solve the problems of high production costs, achieve the goal of reducing area, reducing resistance, and weakening parasitic transistor effects Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

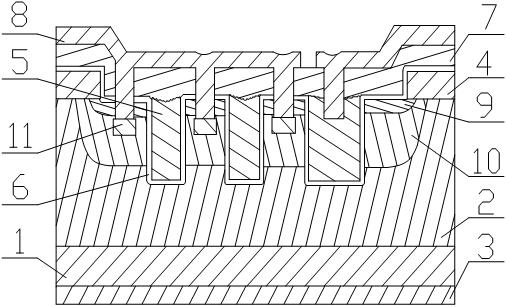

[0034] Such as figure 1 As shown, the trench metal oxide semiconductor field effect transistor includes an N+ substrate layer 1, the upper and lower end surfaces of the N+ substrate layer 1 are respectively provided with an N- epitaxial layer 2 and a back metal layer 3, and the back metal layer 3 forms a drain electrode. An annular field oxide layer 4 is arranged on the upper end of the N-epitaxial layer 2, and the N-epitaxial layer 2 is provided with a groove, and the groove is filled with a doped polysilicon layer 5, and the doped substance is preferably phosphorus or arsenic, Concentration order of magnitude 10 20 cm -3 , As preferably, the polysilicon layer 5 is 4800 Angstroms higher than the level of the trench opening. Between the N-epitaxial layer 2 and the polysilicon layer 5, the upper end surface of the N-epitaxial layer 2, and the upper end surface and the inner sidewall of the field oxide layer 4 are all provided with a gate oxide layer 6, the upper end surface o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com