Method and device for continuously producing lithium iron phosphate by microwave array heating method

A lithium iron phosphate, heating technology, applied in electrical components, battery electrodes, circuits, etc., can solve problems such as unseen and no successful precedents, and achieve the effects of short heating time, consistent size, and reduced energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Disperse ferric phosphate into water to form a suspension with a mass ratio of 1:1; add phosphoric acid to adjust the pH value to 2, and mix it by ball milling for 10 minutes to make a paste; add in a mass ratio of 1:5 to ferric phosphate The pyrrole is ball milled and mixed for 10 minutes, the pyrrole is oxidized by the ferric iron in the ferric phosphate to polymerize, the ferric phosphate is reduced to generate ferrous phosphate, and a polypyrrole-modified ferrous phosphate paste is formed, and the molar ratio of iron:phosphorus is 1:1;

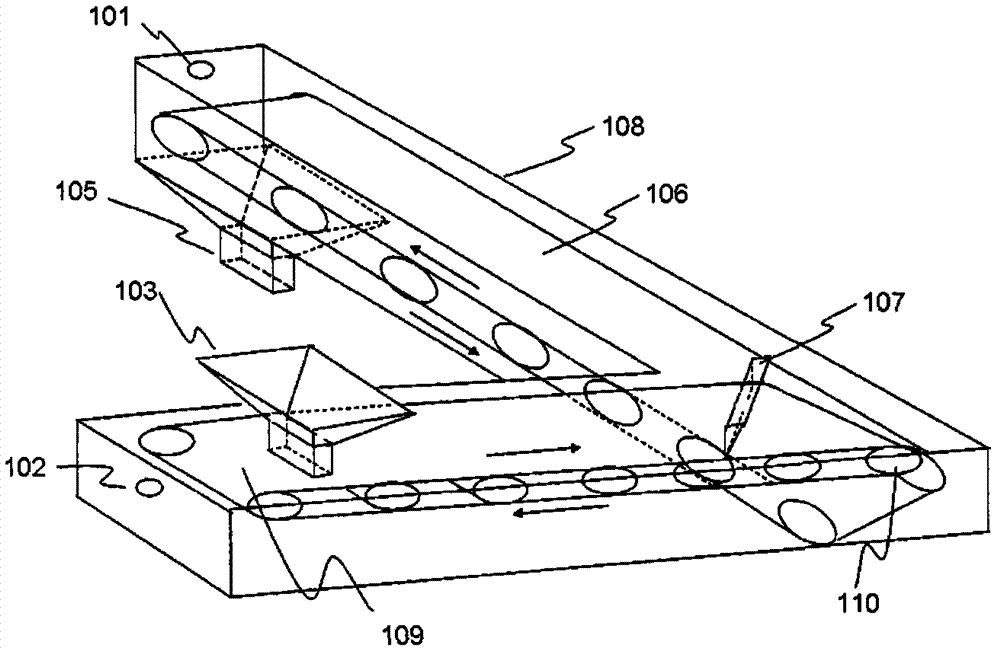

[0041] Take the paste of the above-mentioned polypyrrole modified ferrous phosphate and LiOH·H with a purity of 99.99% 2 O is based on iron: phosphorus: lithium molar ratio is 1:1:1, after stirring and mixing for 10 minutes, polyethylene glycol is added in a mass ratio of 1:0.1 to form a gel, which flows into the microwave array heating furnace through the hopper 103 Conveyor stainless steel belt 109, such as figure 1 shown. By ad...

Embodiment 2

[0043] Disperse ferric phosphate into water to form a suspension with a mass ratio of 1:3; add phosphoric acid to adjust the pH value to 3, and mix it by ball milling for 30 minutes to make a paste; add in a mass ratio of 1:7 to ferric phosphate Pyrrole is ball milled and mixed for 20 minutes, pyrrole is oxidized by ferric phosphate in ferric phosphate to polymerize, and ferric phosphate is reduced to generate ferrous phosphate, forming a polypyrrole-modified ferrous phosphate paste, and the molar ratio of iron:phosphorus is 1:1;

[0044] (2) Take the paste of the above-mentioned polypyrrole-modified ferrous phosphate and LiOH·H with a purity of 99.99%. 2 O is based on iron: phosphorus: lithium molar ratio is 1:1:1, after stirring and mixing for 30 minutes, polyethylene glycol is added in a mass ratio of 1:0.5 to form a gel, which flows into the microwave array heating furnace through the hopper 103 On the transmission stainless steel belt 109. By adjusting the feeding speed ...

Embodiment 3

[0047] Disperse ferric phosphate into water to form a suspension with a mass ratio of 1:2; add phosphoric acid to adjust the pH value to 2.5, and mix it by ball milling for 20 minutes to make a paste; add in a mass ratio of 1:6 to ferric phosphate The pyrrole is ball milled and mixed for 15 minutes, the pyrrole is oxidized by the ferric iron in the ferric phosphate to polymerize, the ferric phosphate is reduced to generate ferrous phosphate, and a polypyrrole-modified ferrous phosphate paste is formed, and the molar ratio of iron:phosphorus is 1:1;

[0048] Take the paste of the above-mentioned polypyrrole modified ferrous phosphate and LiOH·H with a purity of 99.99% 2 O is based on iron: phosphorus: lithium element molar ratio is 1: 1: 1, after stirring and mixing for 15 minutes, polyethylene glycol is added in a mass ratio of 1: 0.3 to form a gel, which flows into the microwave array heating furnace through the hopper 103 On the transmission stainless steel belt 109. By adj...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com