Method for preparing quaternized chitosan and plasmid DNA compound particle loaded skin regeneration material

A quaternized chitosan, skin regeneration technology, applied in medical science, prosthesis, etc., can solve the problems of repeated operation of growth factors, instability of growth factors, easy degradation, etc., to reduce scar hyperplasia, good Histocompatibility, effect of promoting healing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

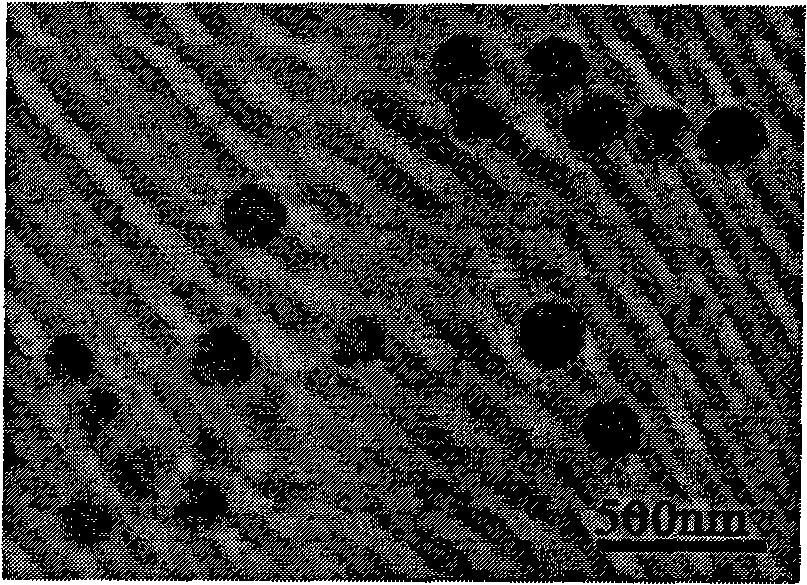

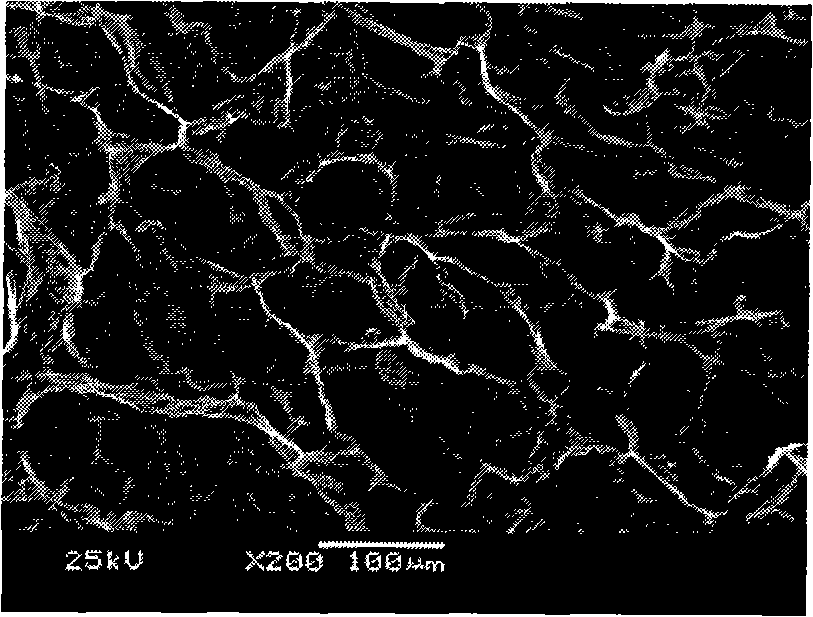

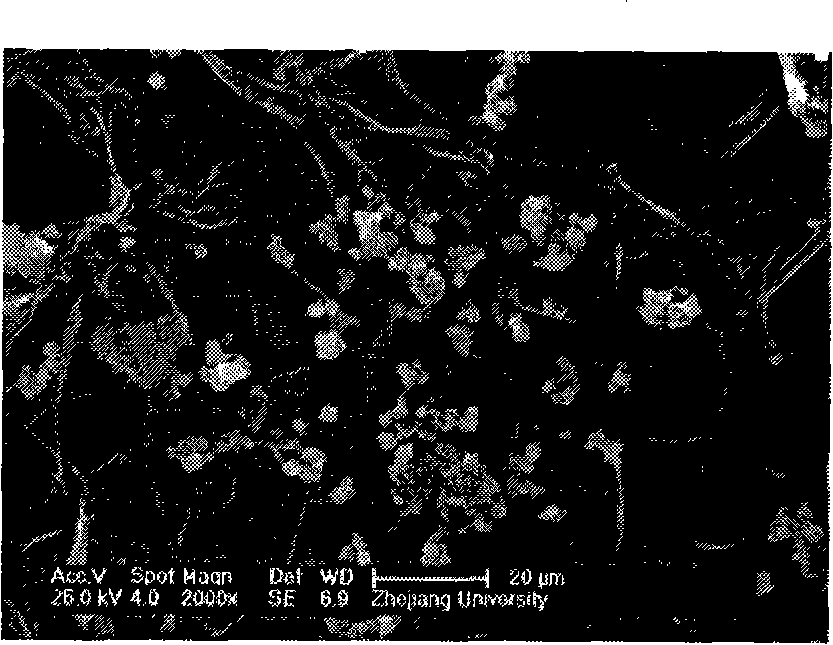

[0030] Dissolve quaternized chitosan in phosphate buffer to prepare 1 mg / mL quaternized chitosan solution, filter and sterilize through a 0.22 μm filter membrane; dissolve pDNA-PDGF in phosphate buffer Prepare a 0.1 mg / mL solution; mix the pDNA-PDGF solution and the quaternized chitosan solution in equal proportions, vibrate vigorously to mix evenly, and let stand to prepare a quaternized chitosan / pDNA-PDGF composite particle solution. Chitosan and collagen are prepared into a solution with a mass concentration of 0.1% by acetic acid solution with a mass concentration of 0.3%, and the mass ratio of chitosan and collagen is 5:5, and the collagen-chitosan blend is injected into the mold The collagen-chitosan three-dimensional porous scaffold was obtained by freeze-drying at -5°C, cross-linked with 0.1% glutaraldehyde for 48 hours, washed several times with triple distilled water, and freeze-dried at -5°C. α-octyl cyanoacrylate with good biocompatibility at 0.5 mg / cm 2 The amoun...

Embodiment 3

[0032] Dissolve quaternized chitosan in phosphate buffer to prepare 10mg / mL quaternized chitosan solution, filter and sterilize through a 0.22μm filter membrane; dissolve pDNA-aFGF in phosphate buffer Prepare a 2 mg / mL solution; mix the pDNA-aFGF solution and the quaternized chitosan solution in equal proportions, vibrate vigorously to mix evenly, and let stand to prepare a quaternized chitosan / pDNA-aFGF composite particle solution. Chitosan and collagen are prepared into a solution with a mass concentration of 0.5% by acetic acid solution with a mass concentration of 0.3%, and the mass ratio of chitosan and collagen is 2: 8, and the collagen-chitosan blend is injected into the mold The collagen-chitosan three-dimensional porous scaffold was obtained by freeze-drying at -20°C, cross-linked with 0.25% glutaraldehyde for 24 hours, washed several times with triple distilled water, and freeze-dried at -20°C. The silicone adhesive with good biocompatibility was added at 0.1mg / cm 2...

Embodiment 4

[0034] Dissolve quaternized chitosan in phosphate buffer to prepare 10mg / mL quaternized chitosan solution, filter and sterilize through a 0.22μm filter membrane; dissolve pDNA-bFGF in phosphate buffer Prepare a 2 mg / mL solution; mix the pDNA-bFGF solution and the quaternized chitosan solution in equal proportions, vibrate vigorously to mix evenly, and let stand to prepare a quaternized chitosan / pDNA-bFGF composite particle solution. Chitosan and collagen are prepared into a solution with a mass concentration of 1% by acetic acid solution with a mass concentration of 3%, and the mass ratio of chitosan and collagen is 1:9, and the collagen-chitosan blend is injected into the mold The collagen-chitosan three-dimensional porous scaffold was obtained by freeze-drying at -20°C, cross-linked with 0.5% glutaraldehyde for 24 hours, washed several times with triple distilled water, and freeze-dried at -20°C. The silicone adhesive with good biocompatibility was added at 0.2mg / cm 2 The a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com