Coal gas methanation catalyst and preparation method thereof

A catalyst, methanation technology, applied in physical/chemical process catalysts, chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, etc. Problems such as the flying temperature of the bed layer, to achieve the effect of increasing the dispersion, not easy to deposit carbon, and conducive to diffusion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] a. Al(NO 3 ) 3 9H 2 O, CTAB, ethanol and water are mixed to obtain a transparent solution; then aluminum nitrate and NH 3 ·H 2 The molar ratio of O is 1:10, add ammonia water, stir quickly to disperse the system; then add large mesoporous alumina, large mesoporous alumina and Al(NO 3 ) 3 9H 2 The molar ratio of O is 0.6, stir evenly, and put it in a water bath at 50°C for 20 hours to obtain a wet gel;

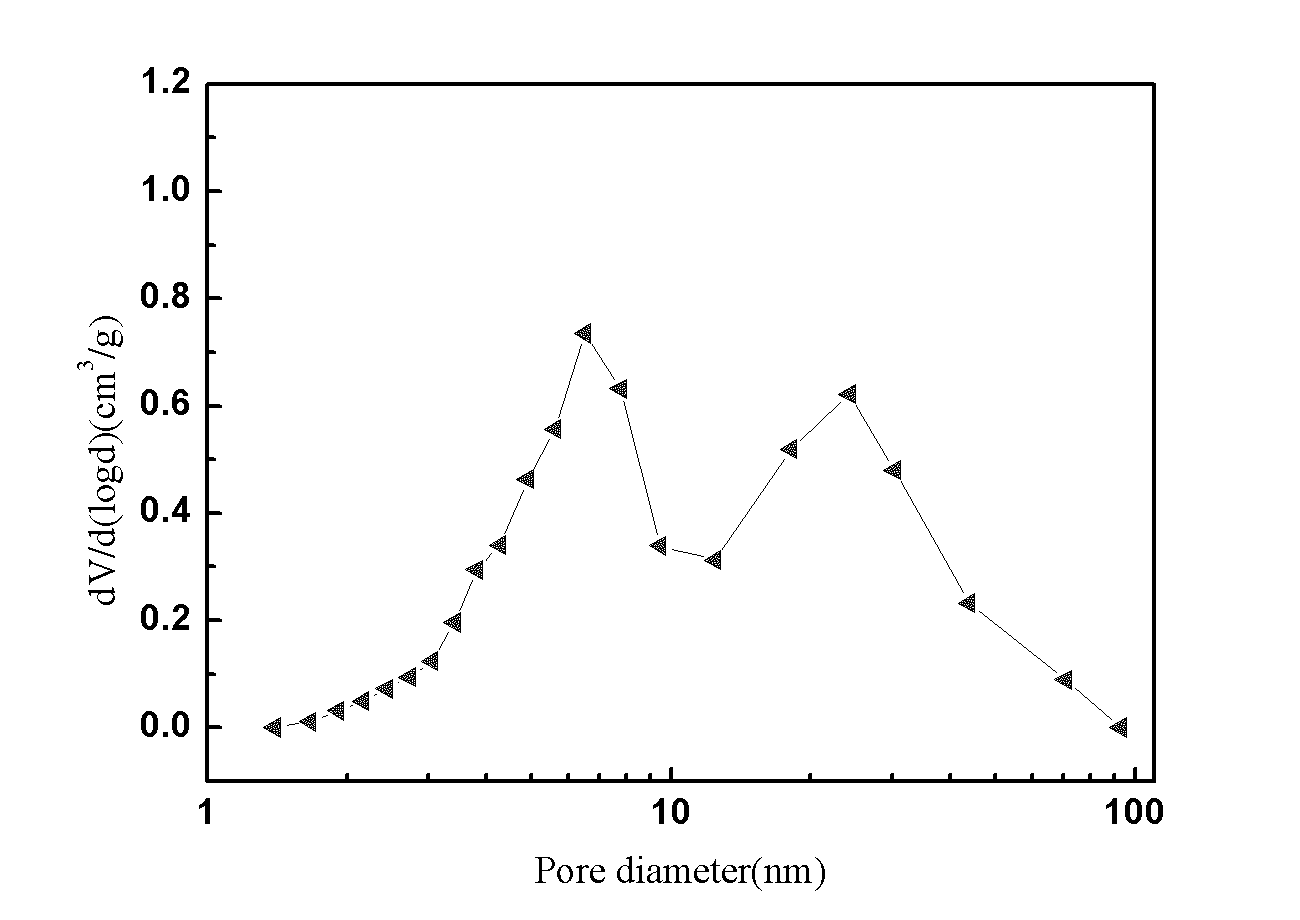

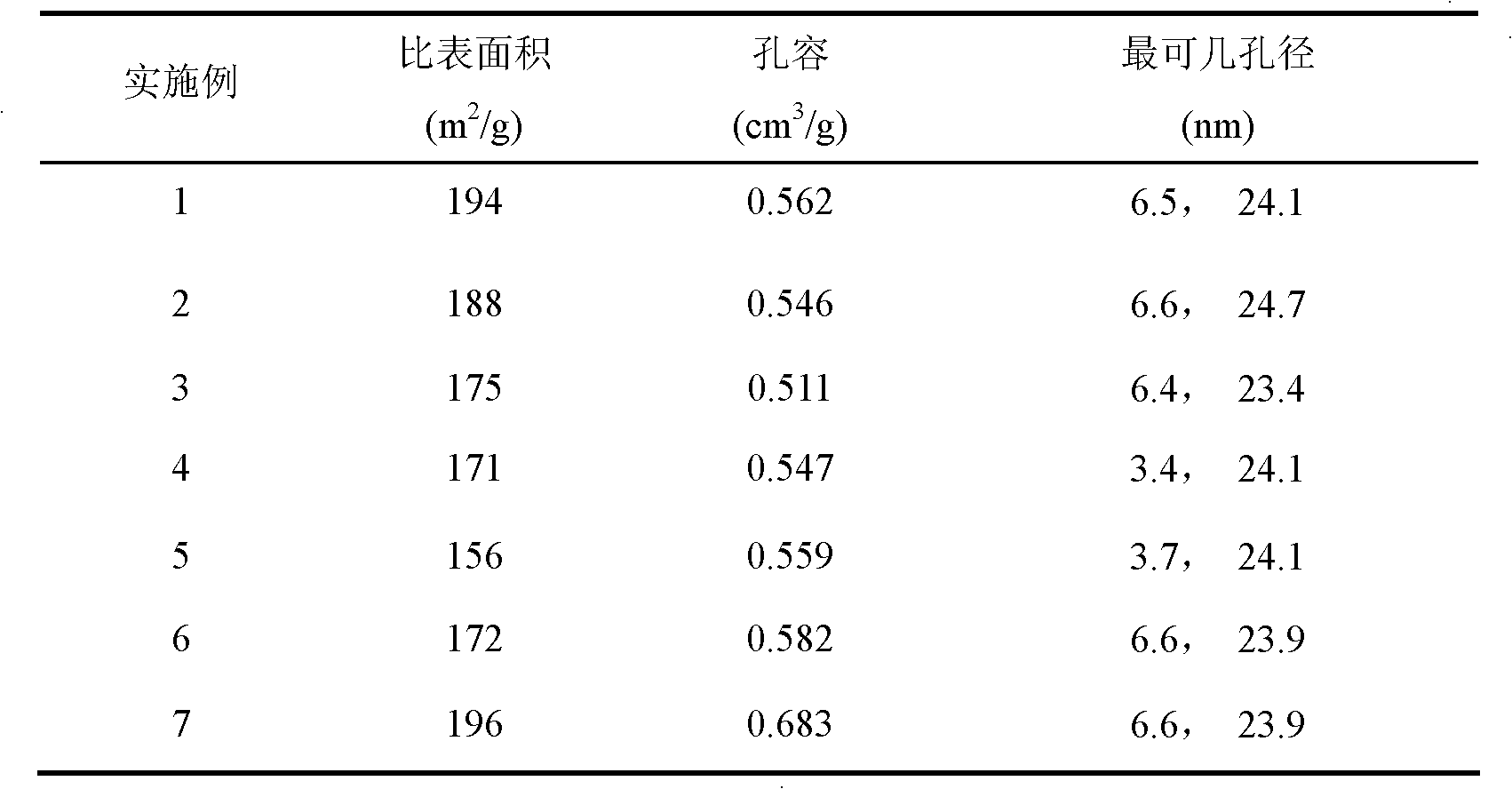

[0027] b. Remove the supernatant of the wet gel, dry the resulting product in a drying oven at 80°C for 20h, grind it into powder, and then bake it at 600°C for 3h to remove the template agent, and obtain Al with double mesoporous distribution 2 o 3 Carrier, the most probable diameter of the small mesopore is 6.5nm, the most probable diameter of the large mesopore is 24.1nm, and the specific surface area is 194m 2 / g, the pore volume is 0.56cm 3 / g;

[0028] c. Then the prepared γ-Al with double mesoporous distribution 2 o 3 Carrier and Ni(NO3) 2 .6H 2 O in...

Embodiment 2

[0031] Al(NO 3 ) 3 9H 2 O, CTAB, ethanol, and water have a molar ratio of 1:0.20:10:90 to obtain a transparent solution; according to aluminum nitrate: NH 3 ·H 2 Add ammonia water at a molar ratio of O to 1:8, stir rapidly to disperse the system, and then add an appropriate amount of large mesoporous alumina, large mesoporous alumina and Al(NO 3 ) 3 9H 2 The molar ratio of O is 0.8, and the mixture is evenly stirred. Aging treatment in a water bath at 60°C for 15 hours to obtain a wet gel; remove the supernatant of the wet gel, dry the resulting product in a drying oven at 100°C for 18 hours, and then bake at 550°C for 4 hours to remove the template agent, namely γ-Al with double mesoporous distribution 2 o 3 , the most probable diameter of small pores is 6.6nm, the most probable diameter of large pores is 24.7nm, and the specific surface area is 188m 2 / g, the pore volume is 0.55cm 3 / g;

[0032] Then the prepared γ-Al 2 o 3 Carrier and La(NO3) 3 .6H 2 The mass...

Embodiment 3

[0035] Al(NO 3 ) 3 9H 2 The molar ratio of O, CTAB, ethanol, and water is 1:0.22:12:88, and a transparent solution is obtained. According to aluminum nitrate: NH 3 ·H 2 O is 1:10, add ammonia water in a molar ratio, and stir rapidly to disperse the system. Then add an appropriate amount of large mesoporous alumina, large mesoporous alumina and Al(NO 3 ) 3 9H 2 The molar ratio of O is 1.25, stir well. Place it in a water bath at 50°C for aging treatment for 20 hours to obtain a wet gel. Remove the supernatant, dry the obtained product in a drying oven at 80°C for 20 hours, take it out, grind it into powder, and then bake it at 600°C for 3 hours to remove the template agent, and then obtain Al with double mesoporous distribution. 2 o 3 , the most probable diameter of small pores is 6.4nm, the most probable diameter of large pores is 23.4nm, and the specific surface area is 175m 2 / g, the pore volume is 0.51cm 3 / g.

[0036] Then the prepared γ-Al 2 o 3 Carrier and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com