Alkali lignin-phenol-sodium sulfanilate-formaldehyde polycondensate and preparation method thereof

A technology of sodium sulfanilate and formaldehyde polycondensation polymer is applied in the field of coal-water slurry additives to achieve the effects of simple production process, easy storage and transportation, and improved comprehensive performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

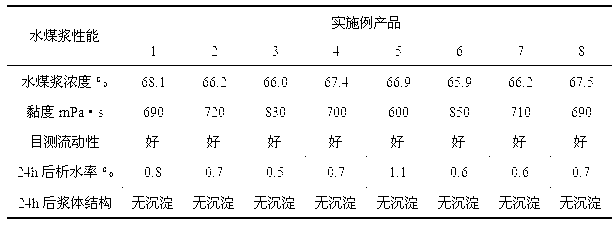

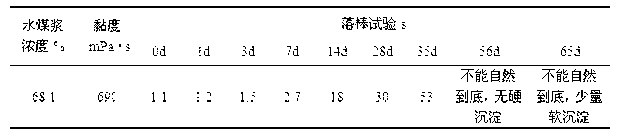

Examples

preparation example Construction

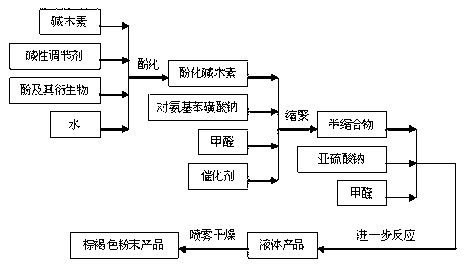

[0043] The specific steps of the preparation method are:

[0044] 1) Preparation of phenolized alkali lignin: the alkali lignin, alkali regulator, phenol and its derivatives and water are reacted at 90-120°C for 1.0-3.0h to obtain phenolized alkali lignin;

[0045] 2) Preparation of semi-condensate: Add catalyst to the phenolic alkali lignin to react for 30 minutes, then add sodium p-aminobenzene sulfonate and half of the formaldehyde solution to continue the reaction for 2.0 to 4.0 hours, the reaction temperature is 90 to 120 ℃, preparation Alkali lignin-phenol-sodium p-aminobenzenesulfonate-formaldehyde semi-condensate;

[0046] 3) Preparation of the product: add sodium sulfite and the other half of the formaldehyde solution, and react for a further 2.0-4.0h at a reaction temperature of 90-120℃ to obtain a liquid alkali lignin-phenol-sodium p-aminobenzenesulfonate-formaldehyde condensation After spray drying, a powder product can be obtained.

[0047] The components and mass parts ...

Embodiment 1

[0061] 1) The raw materials used in this embodiment are as follows:

[0062] Alkali lignin (extracted from the black liquor of eucalyptus pulp by the sulfate method): 100 kg; alkaline regulator (sodium hydroxide): 2 kg; sodium sulfite: 10 kg; phenol and its derivatives (bisphenol A): 115 kg ; Sodium p-aminobenzene sulfonate: 205 kg; formaldehyde (addition in 2 times, 37% content): 150 kg; catalyst (hydrogen peroxide / copper nitrate / sodium thiosulfate, mass ratio 3:2:1) : 12 kg; water: 406 kg.

[0063] 2) The preparation process steps and process parameters of this embodiment:

[0064] (1) Preparation of phenolized alkali lignin: add 100 kg of alkali lignin, 2 kg of sodium hydroxide, 115 kg of bisphenol A and 406 kg of water into the reactor, slowly increase the temperature to 100°C, and react for 2.0 hours to obtain phenolization Alkali lignin.

[0065] (2) Preparation of alkaline lignin-phenol-sodium p-aminobenzenesulfonate-formaldehyde semicondensate: add 12 kg of catalyst hydrogen...

Embodiment 2

[0068] 1) The raw materials used in this embodiment are as follows:

[0069] Alkali lignin (extracted from the black liquor of Masson pine pulp by the sulfate method): 80 kg; alkaline regulator (sodium tetraborate): 18 kg; sodium sulfite: 64 kg; phenol and its derivatives (phenol): 55 kg; Sodium aminobenzene sulfonate: 80 kg; formaldehyde (add in 2 times, 37% content): 115 kg; catalyst (potassium permanganate / ferrous sulfate, mass ratio 1:1): 3 kg; water: 415 kilogram.

[0070] 2) The preparation process steps and process parameters of this embodiment:

[0071] (1) Preparation of phenolized alkali lignin: add 80 kg of alkali lignin, 18 kg of sodium tetraborate, 55 kg of phenol and 415 kg of water into the reactor, slowly increase the temperature to 90℃, and obtain phenolized alkali lignin after 2.5 hours of reaction Vegetarian.

[0072] (2) Preparation of alkali lignin-phenol-sodium p-aminobenzenesulfonate-formaldehyde semicondensate: Add 3 kg of catalyst potassium permanganate / ferr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com