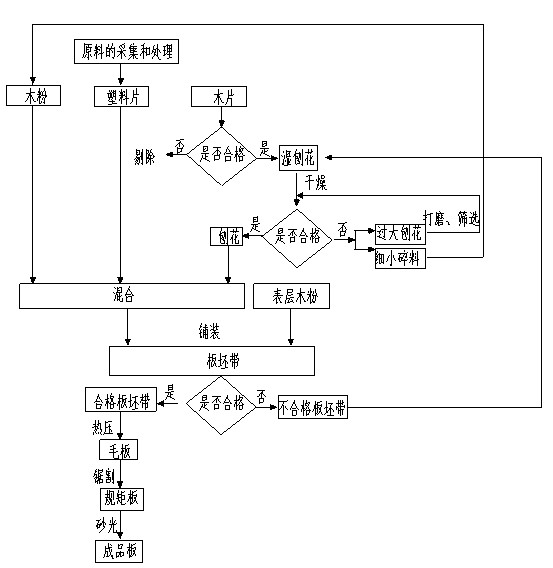

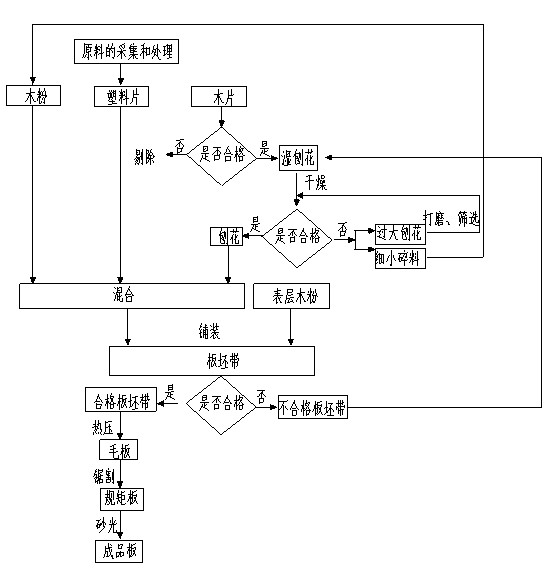

Production process for wood-plastic biological composite board

A production process and composite board technology, which is applied in the direction of wood processing appliances, household components, flat products, etc., can solve the problems of continuous production of wood-plastic composite board products, poor stability of composite particle board slabs, and inability to obtain composite particle boards, etc., to achieve The surface density and core layer density are controllable and stable, reducing occupation and reducing the effect of scrap rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be described in detail below in conjunction with specific embodiments. The invention discloses a wood-plastic biological composite board production process, the method and steps of the production process are as follows:

[0042] 1. Raw material collection and processing:

[0043] 1.1 The collected stumps, branches, wood processing residues, etc. are transported by the loader to the side of the feeding belt conveyor, sent to the belt conveyor manually, and then enter the drum chipper for processing into wood chips. The chipped wood chips go through the spiral The conveyor and belt conveyor are sent to the wood chip warehouse for storage;

[0044] 1.2 Make wood powder from plant woody raw materials. The so-called plant woody raw materials refer to small firewood, rice husks, peanut shells, wheat straw, sawdust, etc., and put the powder made of one or several substances into Stored in wood flour silos;

[0045] 1.3 The purchased plastics, suc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com