Preparation method of high-purity hydrated alumina

A technology of pure hydration and alumina, which is applied in the field of metal-organic compound synthesis, can solve problems such as the troublesome recycling of hydrous isopropanol, the difficulty in preparing metal aluminum powder, and the high melting point of aluminum isopropoxide, so as to achieve short hydrolysis aging time and save Equipment investment and energy consumption, the effect of easy filtration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

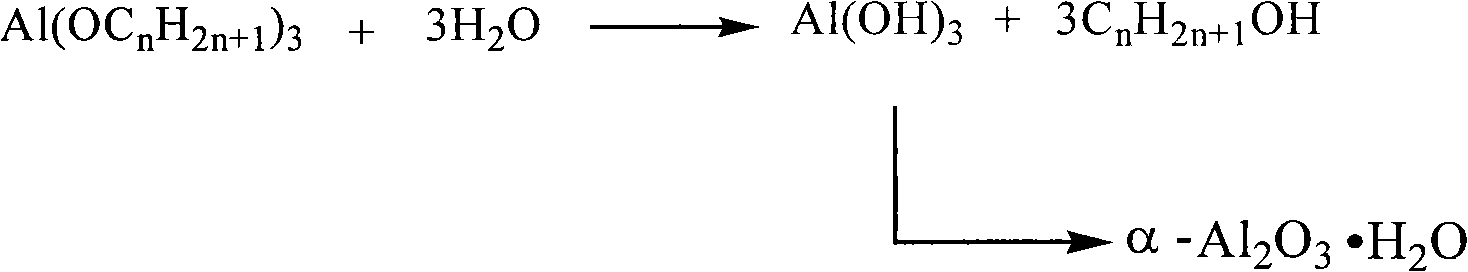

Method used

Image

Examples

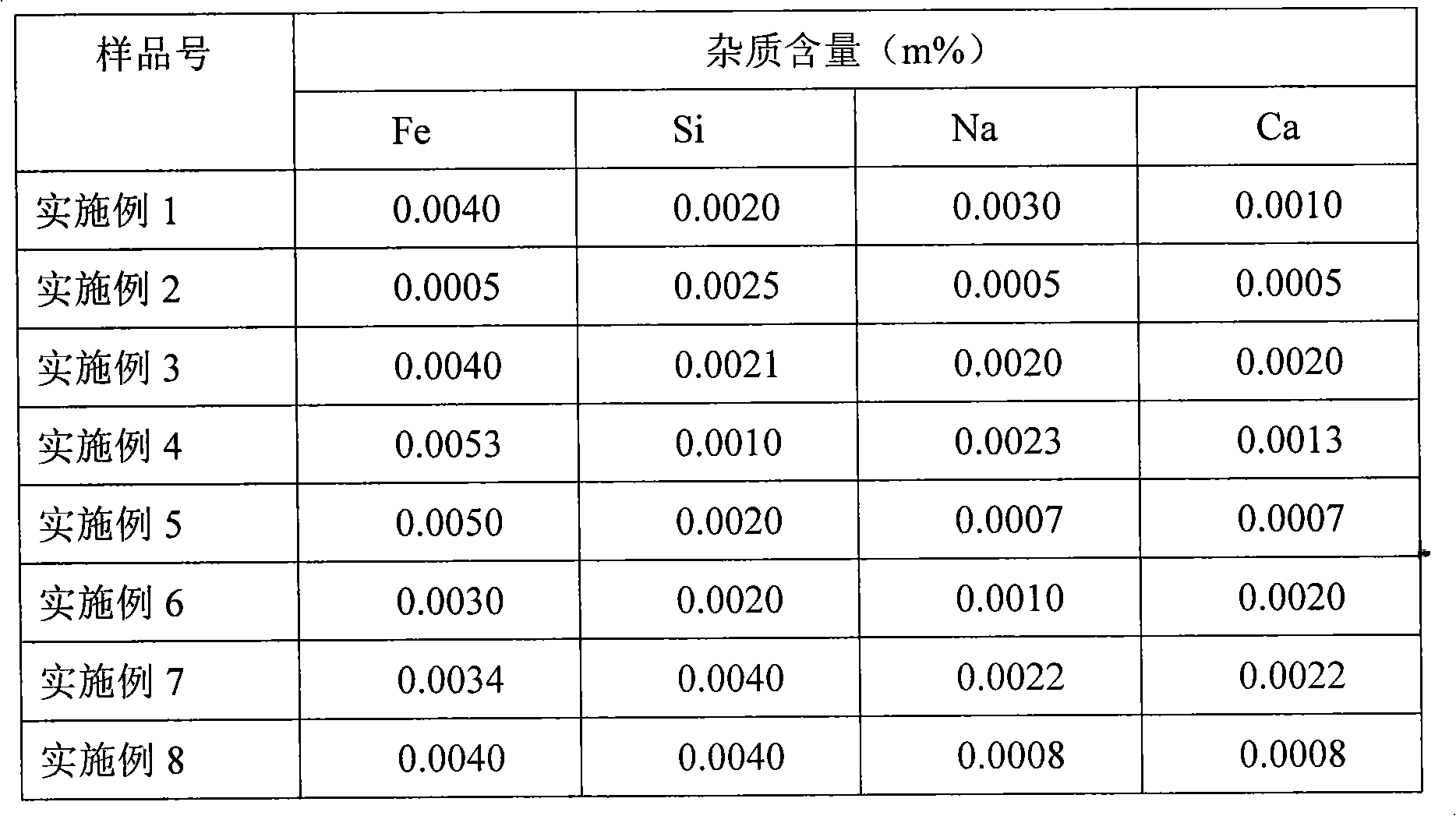

Embodiment 1

[0015] Put 27g of aluminum ingots, 1.33g of anhydrous aluminum trichloride and 50g of n-hexanol (water content less than 0.2%) in a 1L four-neck flask with a condenser tube, and after reflux for 0.5h, drop 256g of n-hexanol into the flask and react under reflux 1h, filtered while hot. The filtrate was put into a 2L autoclave at a temperature of 80°C, and after adding 400 g of deionized water at a temperature of 80°C, the system was sealed. Raise the temperature to 120°C, perform hydrolysis for 2 hours, separate the alcohol, then add 500g of deionized water at 95°C, raise the temperature to 115-180°C, age for 5h, evaporate the remaining alcohol, and spray dry to obtain 60g of white alumina. After XRD, differential thermal and ICP-MS analysis, it is proved to be high-purity α--Al 2 o 3 ·H 2 O.

Embodiment 2

[0017] Put 27g of aluminum ingots, 1.33g of anhydrous aluminum trichloride and 50g of n-hexanol (water content less than 0.2%) in a 1L four-neck flask with a condenser tube, and after reflux for 0.5h, add 307g of n-hexanol and react for 0.5 h, filter while hot. The filtrate was put into a 2L autoclave at a temperature of 80°C, and after adding 400 g of deionized water at a temperature of 80°C, the system was sealed. Raise the temperature to 115-180°C, perform a hydrolysis reaction for 2 hours, separate the alcohol, then add 500g of deionized water at 95°C, raise the temperature to 120°C, age for 4 hours, evaporate the remaining alcohol, and spray dry to obtain 60g of white alumina. After XRD, differential thermal and ICP-MS analysis, it is proved to be high-purity α--Al 2 o 3 ·H 2 O.

Embodiment 3

[0019] Put 27g of aluminum wire, 1.3g of anhydrous aluminum trichloride and 50g of n-hexanol into a 2L four-neck flask, and after reacting for 0.5h, add 256g of n-hexanol, reflux for 2h, filter while it is hot, and put the filtrate into a refrigerator with a temperature of 90°C In a 2L autoclave, add 400 g of deionized water at a temperature of 90° C., and then seal the system. Raise the temperature to 130°C, perform hydrolysis reaction for 2 hours, separate the alcohol, then add 500g of deionized water at 95°C, raise the temperature to 130°C, age for 3h, evaporate the remaining alcohol, and spray dry to obtain 60g of white alumina. After XRD, differential thermal and ICP-MS analysis, it is proved to be high-purity α--Al 2 o 3 ·H 2 O.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com