Cured composite material and sand-fixing method for plant greening

A composite material and chemical curing technology, applied in chemical instruments and methods, soil conditioning materials, applications, etc., can solve the problems of easy oxidative degradation, poor stability, etc., achieve fertilizer retention, water evaporation, convenient construction, and improve resistance to UV degradation The effect of the ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] 1. Production of sand body model

[0047] The production method of the test body: put Toyoura standard sand (Toyoura Silica Mining Co., Ltd., density 2.6g / cm2) into a cylindrical abrasive tool (diameter 50mm*height 100mm) 3 ). The thickness of the actually loaded sand is 50mm. The porosity is 40%.

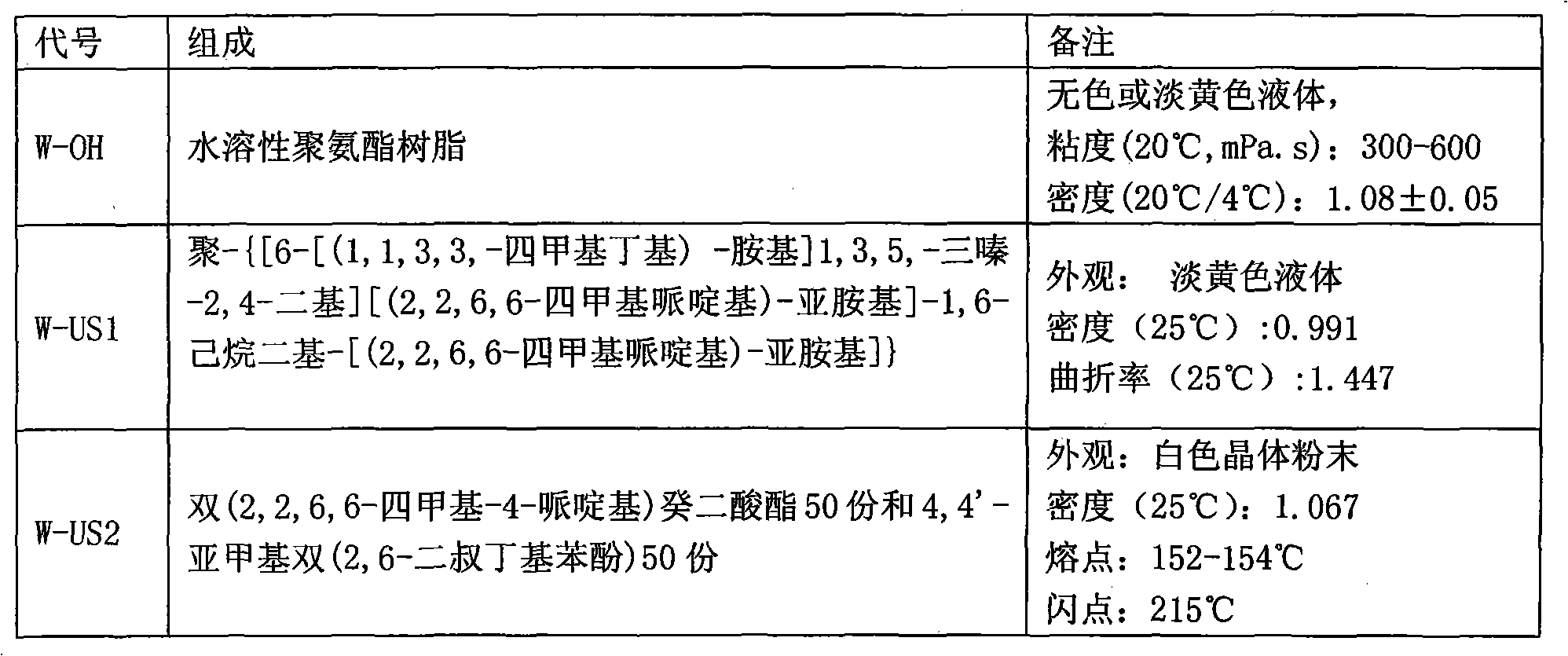

[0048] 2. Preparation of cured composite material for plant greening containing ultraviolet degradation control agent W-US1

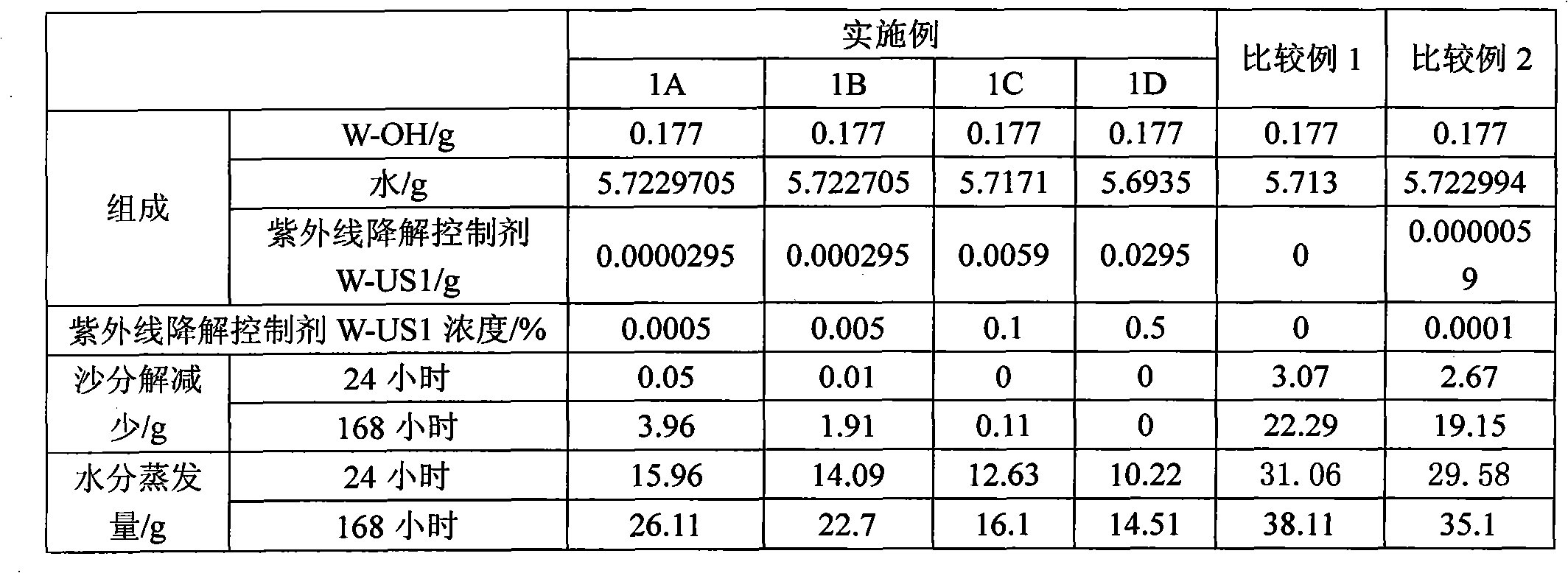

[0049] The W-OH chemical sand-fixing material, water and ultraviolet degradation control agent W-US1 are mixed according to the proportions of Examples 1A-1D in Table 2 in the cured composite material for vegetation greening containing ultraviolet degradation control agent W-US1.

[0050] 3. Spray the above-mentioned solidified composite material for vegetation greening on the surface of the prepared sand body model with a special Y-shaped tube mechanical equipment, and form a porous consolidation layer with a thickness of 5-50mm on the surface of ...

Embodiment 2

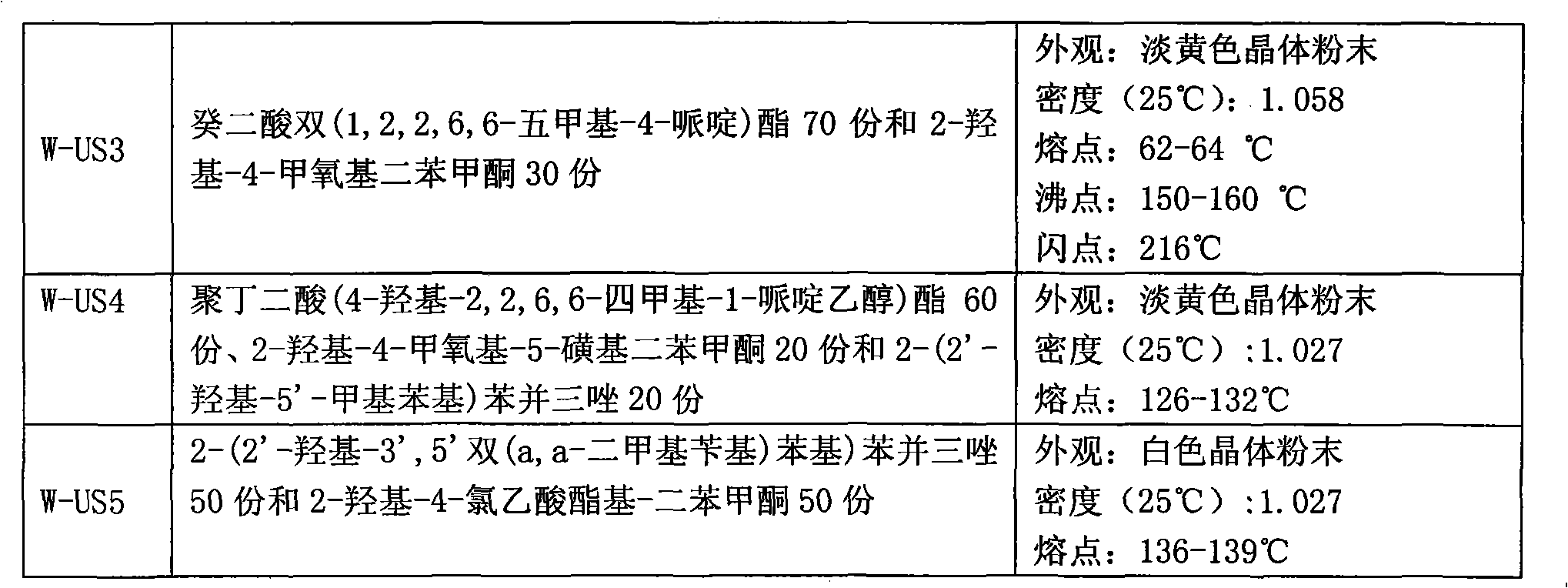

[0059] Except that the ultraviolet degradation control agent W-US2 is used to replace the ultraviolet degradation control agent W-US1 in the cured composite material for vegetation greening, all the others are the same as in Example 1, and each composition is mixed according to the ratio of Examples 2A-2D in Table 3. The test results are recorded in Table 3.

Embodiment 3

[0065] Except that the ultraviolet degradation control agent W-UA3 is used to replace the ultraviolet degradation control agent W-US1 in the cured composite material for vegetation greening, all the others are the same as in Example 1, and each composition is mixed according to the ratio of Examples 3A-3D in Table 4. The test results are recorded in Table 4.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com