Fluidization roasting method for gold sulfide ore

A technology of fluidized roasting and gold ore, which is applied in the field of fluidized roasting of sulfide gold ore, can solve the problems of waste of resources, high environmental protection costs of enterprises, high gold content in cyanidation tailings, and achieve full and complete combustion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

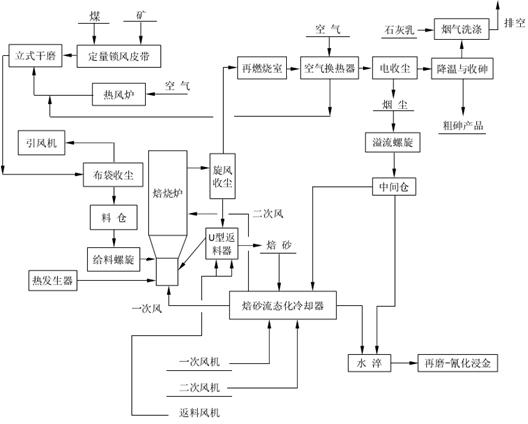

Method used

Image

Examples

Embodiment 1

[0042] The main chemical composition of sulfide gold ore is listed in Table 1.

[0043] Table 1 The chemical element composition (%) of embodiment 1-sulfide gold ore

[0044]

[0045] *Note: The units of Au and Ag are g / t.

[0046] The sulfide gold ore, with 8% water content, is crushed to -8mm, and quantitatively fed into the airlock belt scale at the entrance of the vertical mill, and the crushed coal crushed to -30mm is also quantitatively and evenly fed into the airlock belt scale at the entrance of the vertical mill , the amount of coal added is 3% of the amount of sulfide gold ore, and the sulfide gold ore and coal are sent to the vertical mill through the air lock belt scale for hot air drying and grinding classification. The hot air comes from the hot blast stove, and the temperature of the hot air entering the vertical mill is 300 oC , the hot air temperature at the outlet of the vertical mill is 70 oC , the dried and finely ground mixture of mineral powder an...

Embodiment 2

[0054] The main chemical composition of sulfide gold ore is listed in Table 2.

[0055] Table 2 The chemical element composition (%) of embodiment 2-sulfide gold ore

[0056]

[0057] * Note: The units of Au and Ag are g / t.

[0058] The sulfide gold ore, with a water content of 6%, is crushed to -8mm, and quantitatively fed into the airlock belt scale at the entrance of the vertical mill, and the crushed coal crushed to -30mm is also quantitatively and evenly fed into the airlock belt scale at the entrance of the vertical mill , the amount of coal added is 3% of the amount of sulfide gold ore, and the sulfide gold ore and coal are sent to the vertical mill through the air lock belt scale for hot air drying and grinding classification. The hot air comes from the hot blast stove, and the temperature of the hot air entering the vertical mill is 300 oC , the hot air temperature at the outlet of the vertical mill is 75 oC , the dried and finely ground mixture of mineral pow...

Embodiment 3

[0066] The main chemical composition of sulfide gold ore is listed in Table 3.

[0067] Table 3 The chemical element composition (%) of embodiment 3-sulfide gold ore

[0068]

[0069] * Note: The units of Au and Ag are g / t.

[0070] Feed sulfide gold ore with 8% water content into the air-lock belt scale at the entrance of the vertical mill, and at the same time, crush the coal crushed to -20mm into the air-lock belt scale at the entrance of the vertical mill in a quantitative and uniform manner. The amount of coal added It is 3% of the amount of sulfide gold ore. The sulfide gold ore and coal are sent to the vertical mill through the air lock belt scale for hot air drying and grinding classification. The hot air comes from the hot blast furnace, and the temperature of the hot air entering the vertical mill is 350 oC , the hot air temperature at the outlet of the vertical mill is 85 oC , the dried and finely ground mixture of mineral powder and coal powder is pneumatic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com