Electrolyte for electrochemical mechanical polishing of copper interconnecting layer and preparation method thereof

A mechanical polishing and electrochemical technology, which is applied in the field of electrolyte and its preparation for electrochemical mechanical polishing of copper interconnection layers, can solve the problems of poor surface quality and high surface roughness, and achieve improved surface quality, improved electric field conditions, The effect of improving selective dissolution removal ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

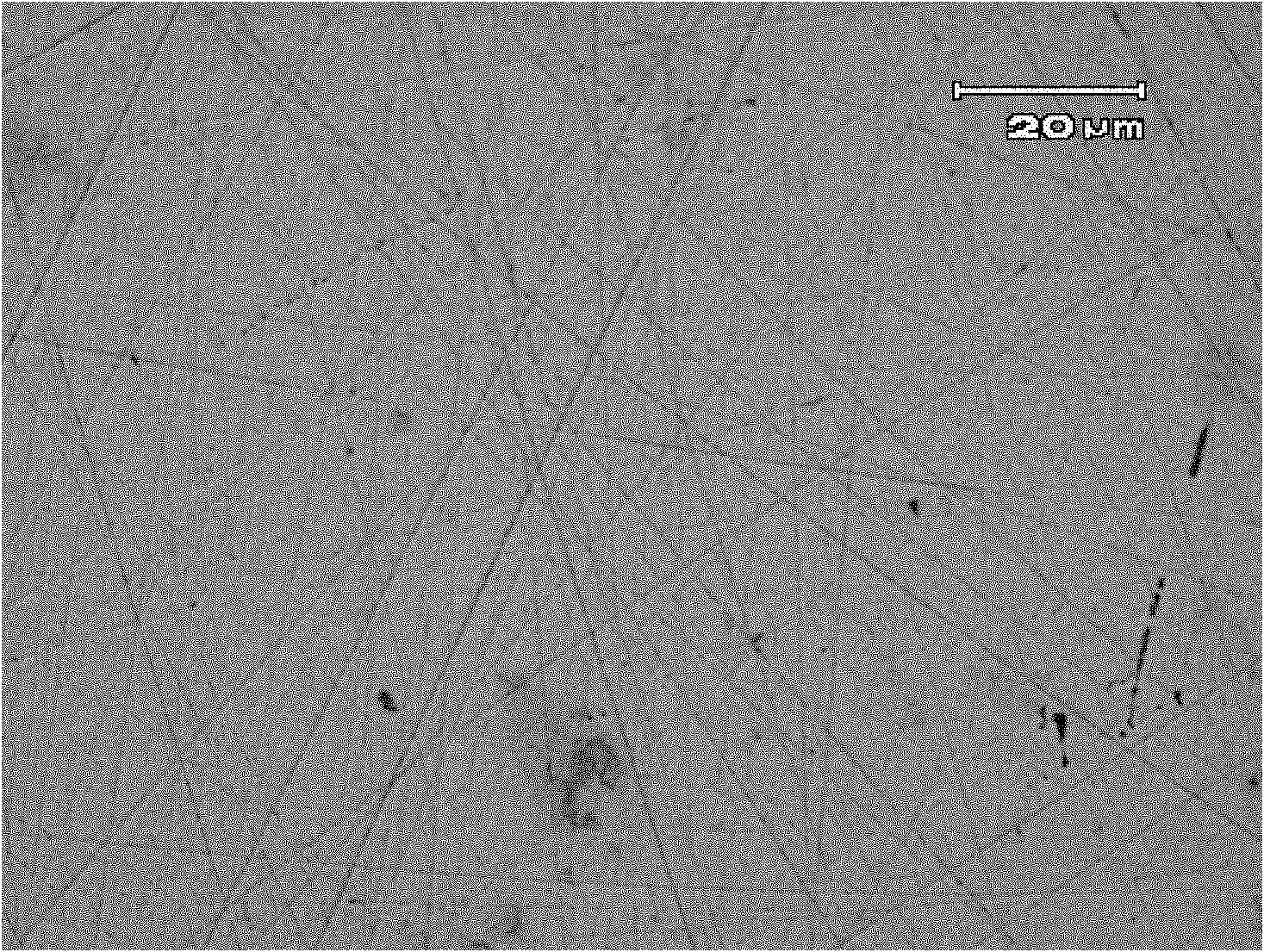

Embodiment 1

[0027] An electrolytic solution for electrochemical mechanical polishing of copper interconnection layers and a preparation method thereof, comprising the steps of:

[0028] 1) According to the proportion of each component in deionized water: complexing agent: 40g / L, inhibitor: 3g / L, abrasive grain: 10g / L; dispersant: 10g / L; deionized water: 100ml; select Raw materials such as complexing agent, inhibitor, abrasive grain, dispersant and deionized water are used for standby;

[0029] The complexing agent is glycine; the inhibitor is thiosalicylic acid; the abrasive particles are rutile titanium dioxide; the dispersant is polyethylene glycol 1000.

[0030] 2) Add the complexing agent and inhibitor into the deionized water according to the above ratio, and stir evenly with a glass rod, so that each substance is fully dissolved in the deionized water;

[0031] 3) On the basis of the electrolyte that has been added with complexing agent and inhibitor, add abrasive particles and dis...

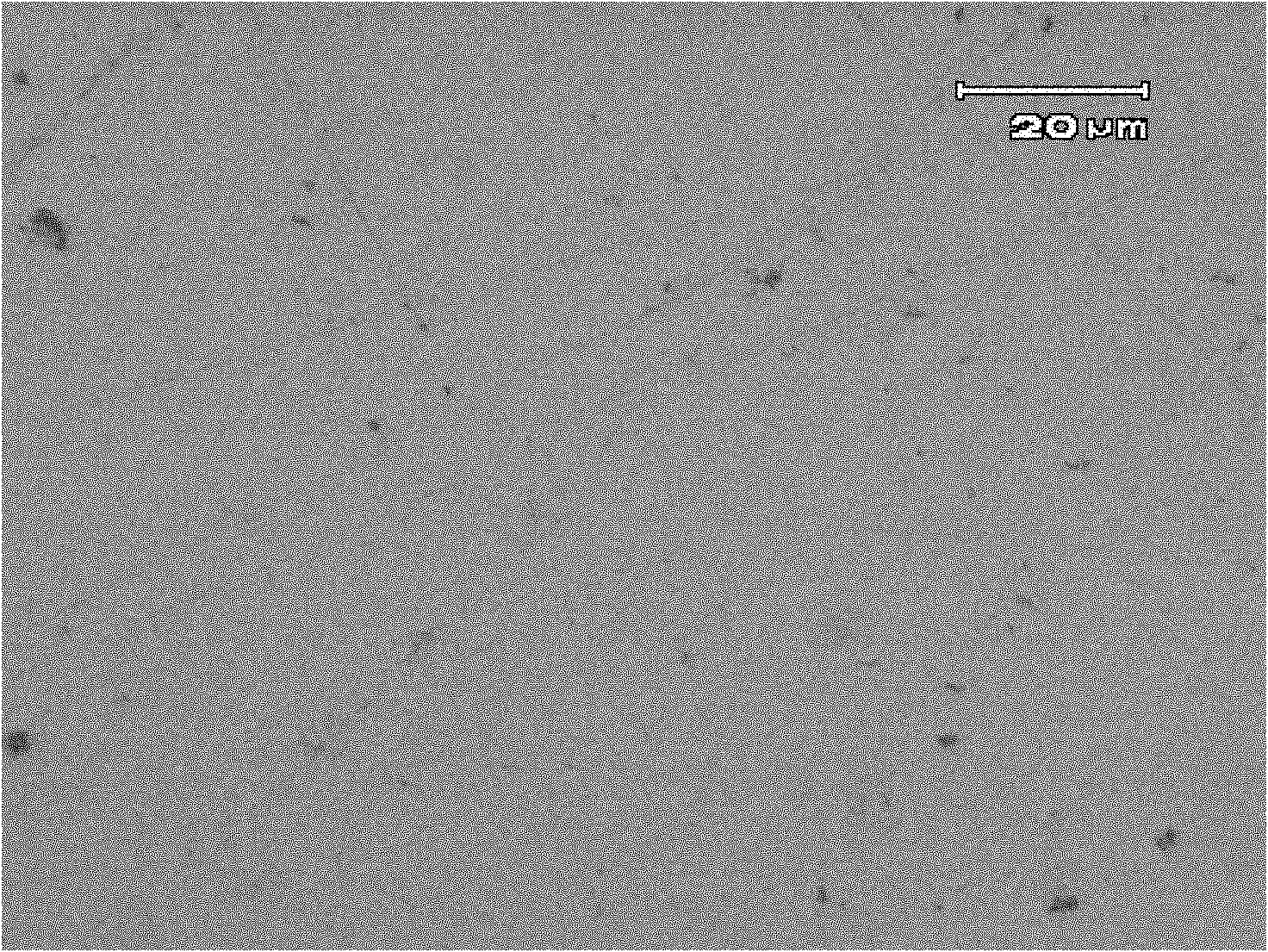

Embodiment 2

[0033] An electrolytic solution for electrochemical mechanical polishing of copper interconnection layers and a preparation method thereof, comprising the steps of:

[0034] 1) According to the proportion of each component in deionized water: complexing agent: 30g / L, inhibitor: 1g / L, abrasive grain: 10g / L; dispersant: 10g / L; deionized water: 100ml; select Raw materials such as complexing agent, inhibitor, abrasive grain, dispersant and deionized water are used for standby;

[0035] The complexing agent is glycine; the inhibitor is benzotriazole; the abrasive grain is rutile titanium dioxide; the dispersant is polyethylene glycol 1000.

[0036] 2) Add the complexing agent and inhibitor into the deionized water according to the above ratio, and stir evenly with a glass rod, so that each substance is fully dissolved in the deionized water;

[0037] 3) On the basis of the electrolyte that has been added with complexing agent and inhibitor, add abrasive particles and dispersant ac...

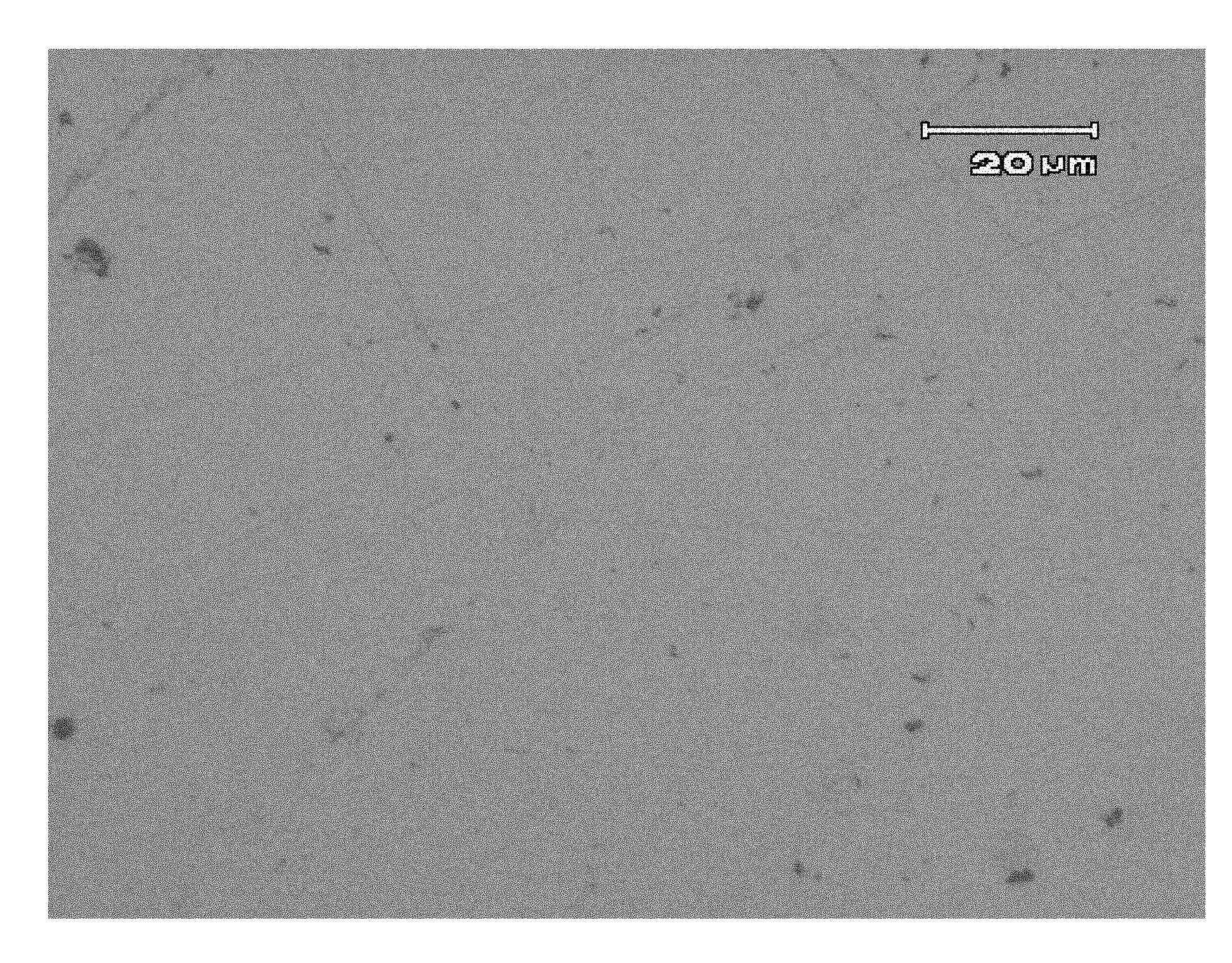

Embodiment 3

[0039] An electrolytic solution for electrochemical mechanical polishing of copper interconnection layers and a preparation method thereof, comprising the steps of:

[0040] 1) According to the proportion of each component in deionized water: complexing agent: 30g / L, inhibitor: 1g / L, abrasive grain: 20g / L; dispersant: 20g / L; deionized water: 100ml; select Raw materials such as complexing agent, inhibitor, abrasive grain, dispersant and deionized water are used for standby;

[0041] The complexing agent is oxalic acid; the inhibitor is thiosalicylic acid; the abrasive particles are anatase titanium dioxide; the dispersant is polyethylene glycol 600.

[0042] 2) Add the complexing agent and inhibitor into the deionized water according to the above ratio, and stir evenly with a glass rod, so that each substance is fully dissolved in the deionized water;

[0043] 3) On the basis of the electrolyte that has been added with complexing agent and inhibitor, add abrasive particles and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com