Preparation method of cysteamine hydrochloride controlled-release feed additive

A cysteamine hydrochloride and feed additive technology, applied in the field of cysteamine hydrochloride feed additives and animal feeds, can solve the problems of loss of physiological activity, poor animal palatability and feed intake, and poor stability. Removal of rotten egg odor and bitterness, protection of physiological activity and stability, enhancement of strength and completeness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

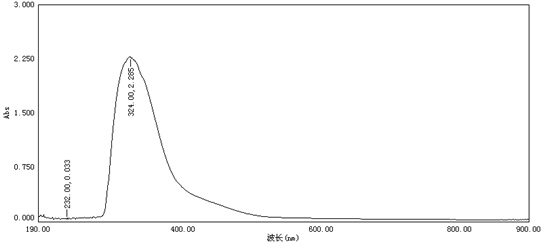

Image

Examples

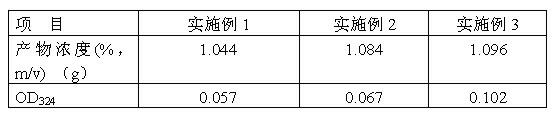

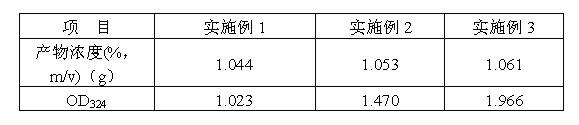

Embodiment 1

[0033] The preparation of the liquid finished product of the present invention: take by weighing 3500 grams of cysteamine hydrochloride, 5700 grams of glucose, and 800 grams of water, adjust to pH3.5 with sodium hydroxide solution after it is mixed uniformly, stirring speed 90 rpm, temperature Control the temperature at 87°C and react for 80 minutes to obtain the liquid finished product of the present invention.

Embodiment 2

[0035] The preparation of the liquid finished product of the present invention: take by weighing 5000 grams of cysteamine hydrochloride, 4500 grams of glucose, and 500 grams of water, mix them evenly, adjust the pH to 4.5 with sodium hydroxide, stir at a speed of 60 rpm, and control the temperature React at 89°C for 60 minutes to obtain the liquid finished product of the present invention.

Embodiment 3

[0037] Preparation of the liquid finished product of the present invention: Weigh 6800 grams of cysteamine hydrochloride, 3000 grams of glucose, and 200 grams of water, mix them evenly, adjust the pH to 5.5 with sodium hydroxide, stir at a speed of 70 rpm, and control the temperature After reacting for 70 minutes at 85°C, the liquid finished product of the present invention was obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com