Simple preparation method of hollow-spherical and flower-shaped indium oxide with secondary structure and application

A secondary structure, indium oxide technology, applied in chemical instruments and methods, analysis by making materials react chemically, inorganic chemistry, etc., can solve the problems of complex operation, high production cost, harsh experimental conditions, etc., and achieve a wide range of sources , low cost, simple and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

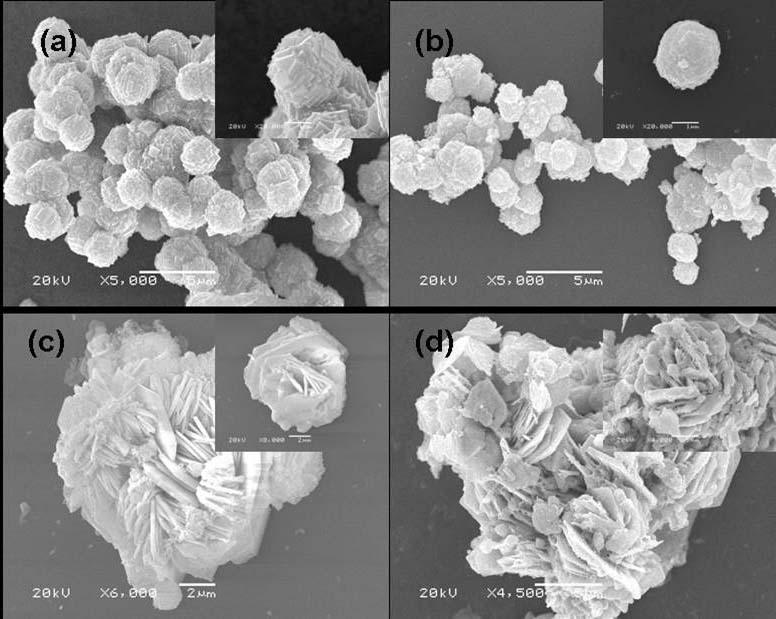

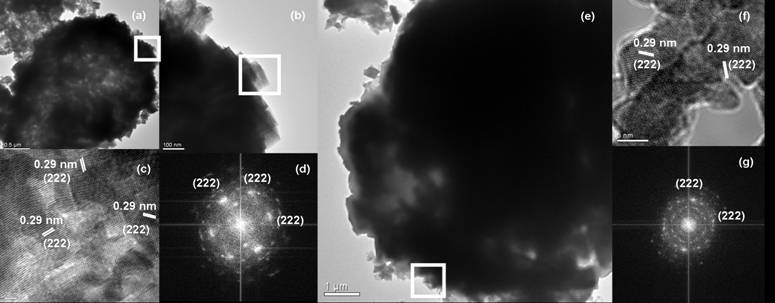

[0025] a) First add 2 mmol of indium chloride and 4 g of SDS into a 50 mL beaker filled with 40 mL of deionized water, then mix and stir for about 20 minutes. Add 4 mL of DMF to the above solution, and continue stirring for about 10 minutes. The solution was transferred into a 60 mL polytetrafluoroethylene-lined autoclave, and after sealing, the autoclave was kept at 160 °C for 10 hours. After 10 hours, the autoclave was taken out, and after being cooled to room temperature, the autoclave was opened, and the product was transferred to a beaker;

[0026] b) Wash the above product repeatedly with deionized water and absolute ethanol. Dry the final white precipitate at 60°C. The white precipitate is the precursor. And perform XRD and SEM characterization on the prepared white precursor;

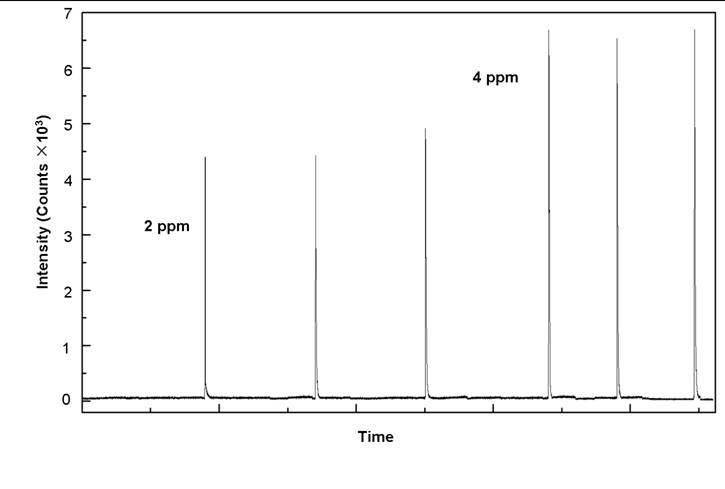

[0027] c) Transfer the dried precursor to a crucible, put the crucible into a muffle furnace at 400°C for 5 hours, take it out, and cool it down to room temperature. The finally obtained ye...

Embodiment 2

[0029] a) First add 2 mmol of indium chloride and 6 g of SDS into a 50 mL beaker filled with 40 mL of deionized water, then mix and stir for about 20 minutes. Add 4 mL of DMF to the above solution, and continue stirring for about 10 minutes. The solution was transferred into a 60 mL polytetrafluoroethylene-lined autoclave, and after sealing, the autoclave was kept at 160° C. for 10 hours. After 10 hours, the autoclave was taken out, and after being cooled to room temperature, the autoclave was opened, and the product was transferred to a beaker;

[0030] b) Wash the above product repeatedly with deionized water and absolute ethanol. Dry the final white precipitate at 60°C. The white precipitate is the precursor. And perform XRD and SEM characterization on the prepared white precursor;

[0031] c) Transfer the dried precursor to a crucible, put the crucible into a muffle furnace at 600°C for 5 hours, take it out, and cool it to room temperature. The finally obtained yellow...

Embodiment 3

[0033] a) First add 2 mmol of indium chloride and 1 g of SDS into a 50 mL beaker filled with 40 mL of deionized water, then mix and stir for about 20 minutes. Add 4 mL of DMF to the above solution, and continue stirring for about 10 minutes. The solution was transferred into a 60 mL polytetrafluoroethylene-lined autoclave, and after sealing, the autoclave was kept at 160° C. for 10 hours. After 10 hours, the autoclave was taken out, and after being cooled to room temperature, the autoclave was opened, and the product was transferred to a beaker;

[0034] b) Wash the above product repeatedly with deionized water and absolute ethanol. Dry the final white precipitate at 60°C. The white precipitate is the precursor. And perform XRD and SEM characterization on the prepared white precursor;

[0035] c) Transfer the dried precursor to a crucible, put the crucible into a muffle furnace at 400°C for 5 hours, take it out, and cool it down to room temperature.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com