High-frequency intelligent response electro-desalting power supply device

A power supply equipment and electric desalination technology, which is applied in the fields of crude oil electric desalination in refineries and oil field electric dehydration, and can solve the problems of large reactors, difficult to reach, and unfavorable crude oil emulsion demulsification.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

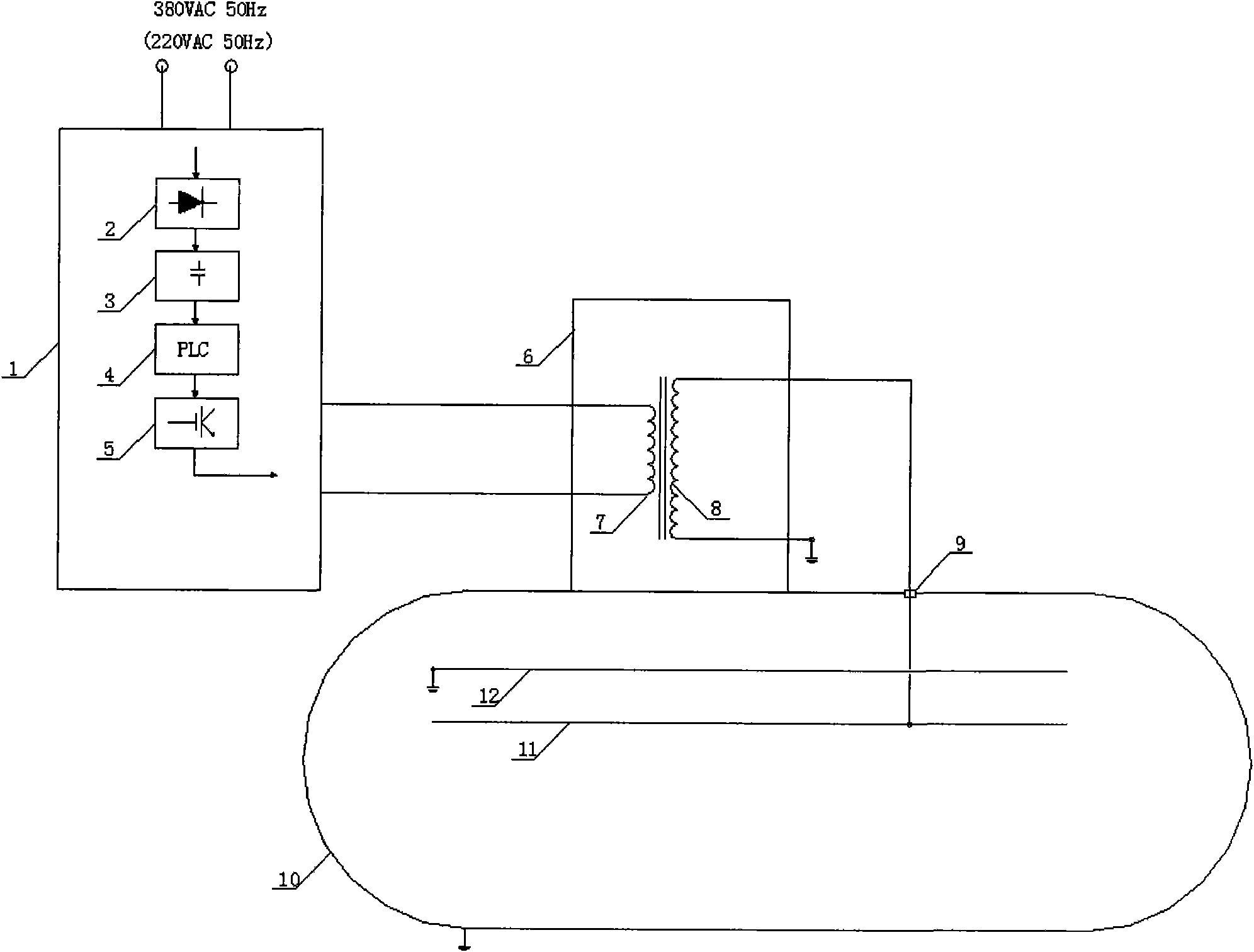

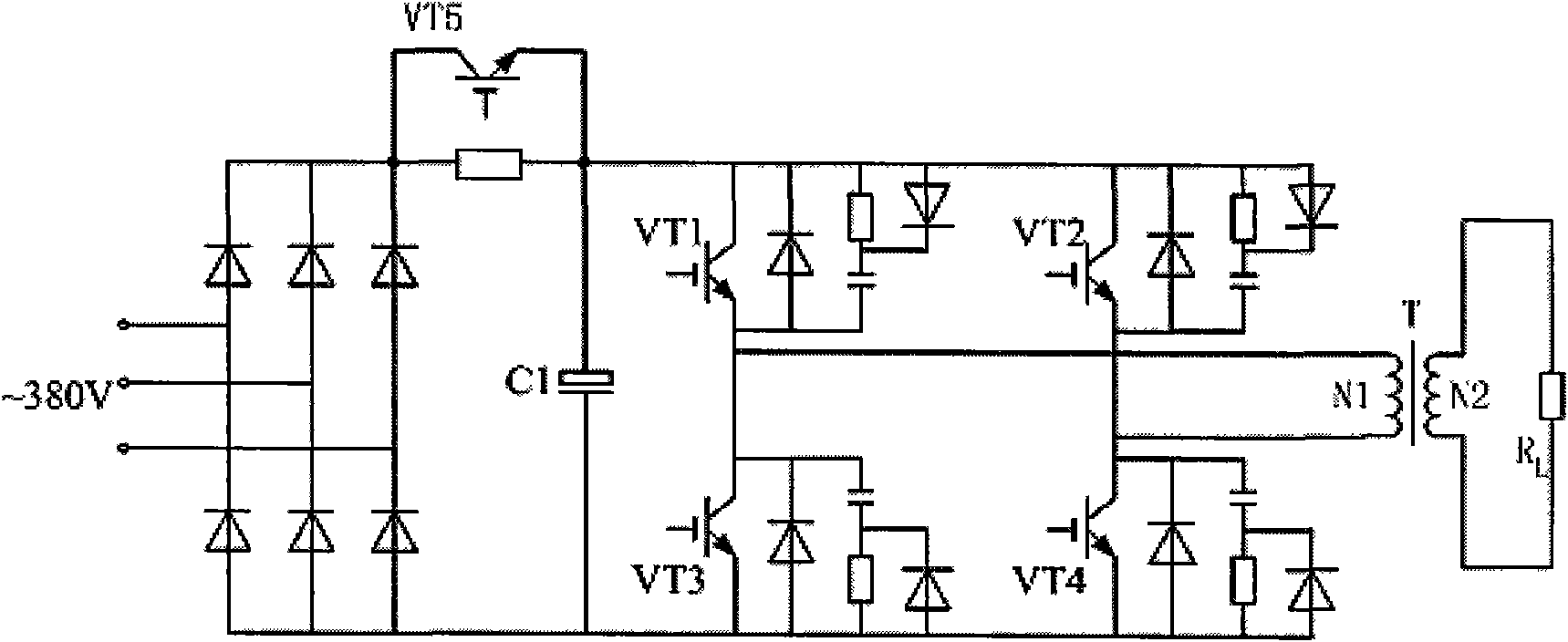

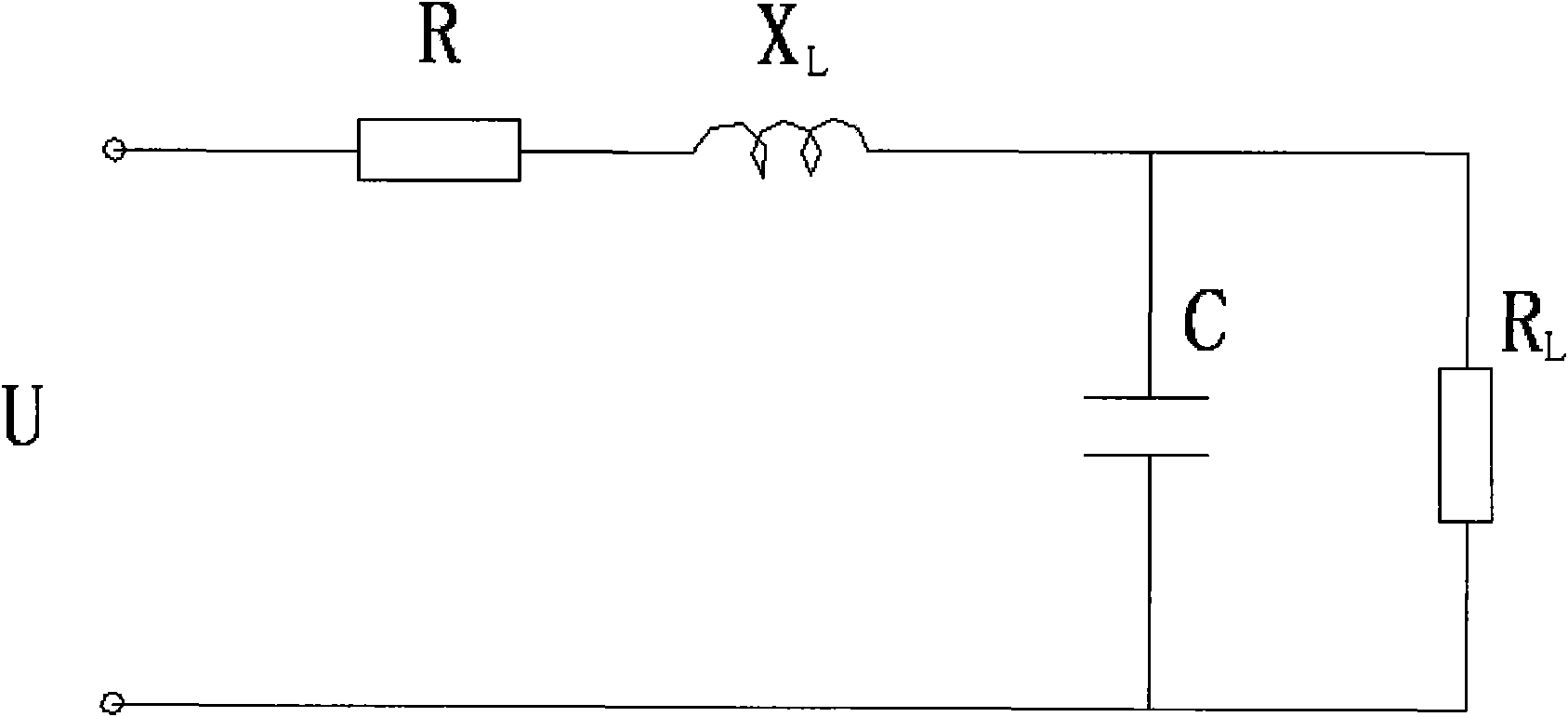

[0016] refer to figure 1 A high-frequency intelligent response control electric desalination and electric dehydration power supply is provided with a high-frequency intelligent response control cabinet 1, an explosion-proof high-frequency transformer 6, a high-voltage electric introduction rod 9, an electric desalination and electric dehydration tank body 10, and an electrode plate 11. The high-frequency intelligent response control cabinet 1 is mainly through the rectification circuit, filter circuit, inverter circuit, protection circuit, output voltage amplitude adjustment circuit, and anti-bias circuit to realize the adjustable voltage between 0-540 volts and the frequency at 50 Adjustable between -20000Hz, the main function of the rectifier circuit is to convert the input three-phase alternating current into direct current. This paper adopts a three-phase full-bridge controllable rectification circuit, which consists of rectifier diodes and IGBT devices to form a three-ph...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com