Comprehensive utilization method for vanadium slag

A technology of vanadium slag and vanadium pentoxide, which is applied in the field of metallurgy, can solve problems such as high pollution, low efficiency, and unsafety, and achieve the effects of high purity, simple process, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

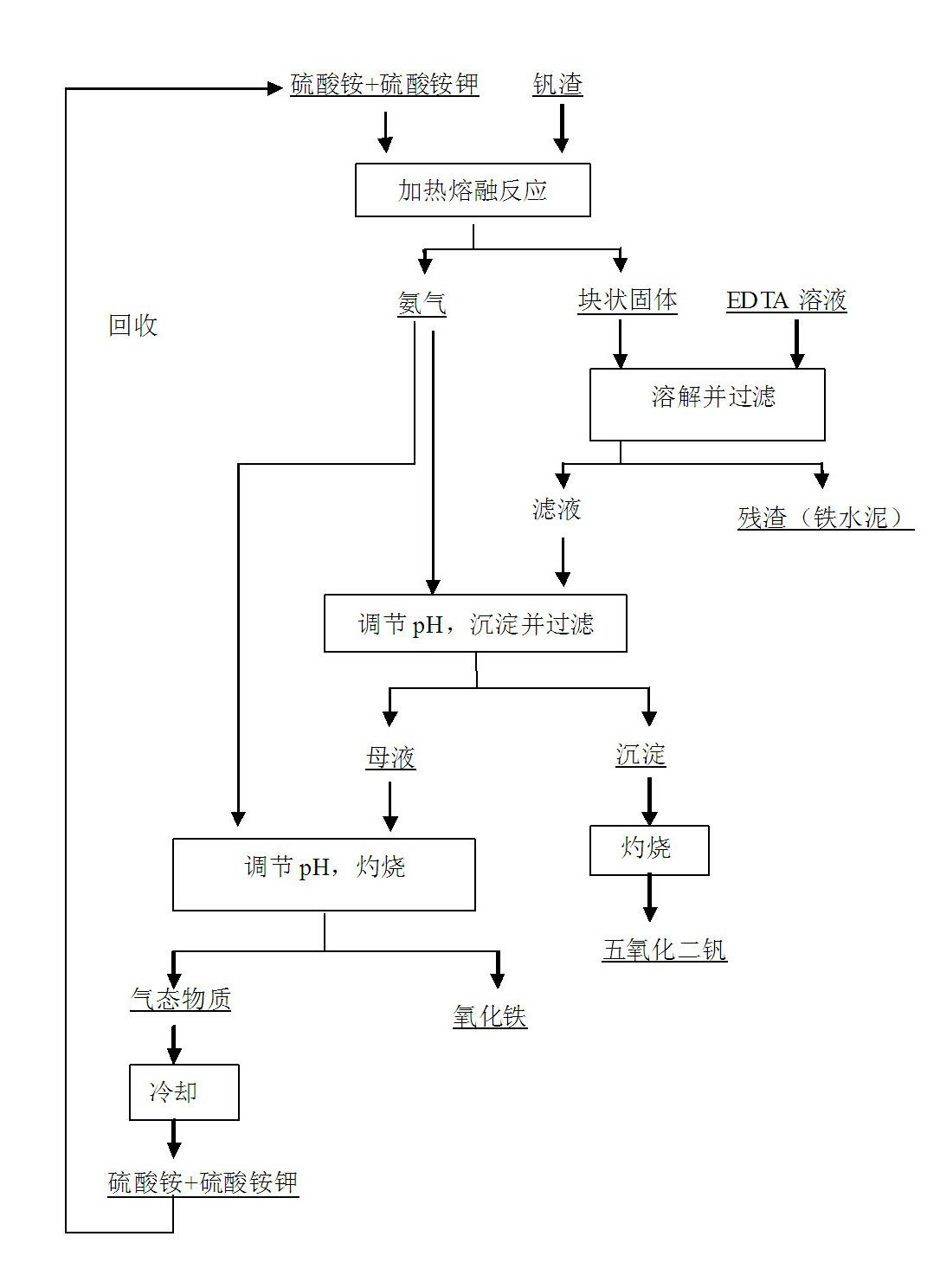

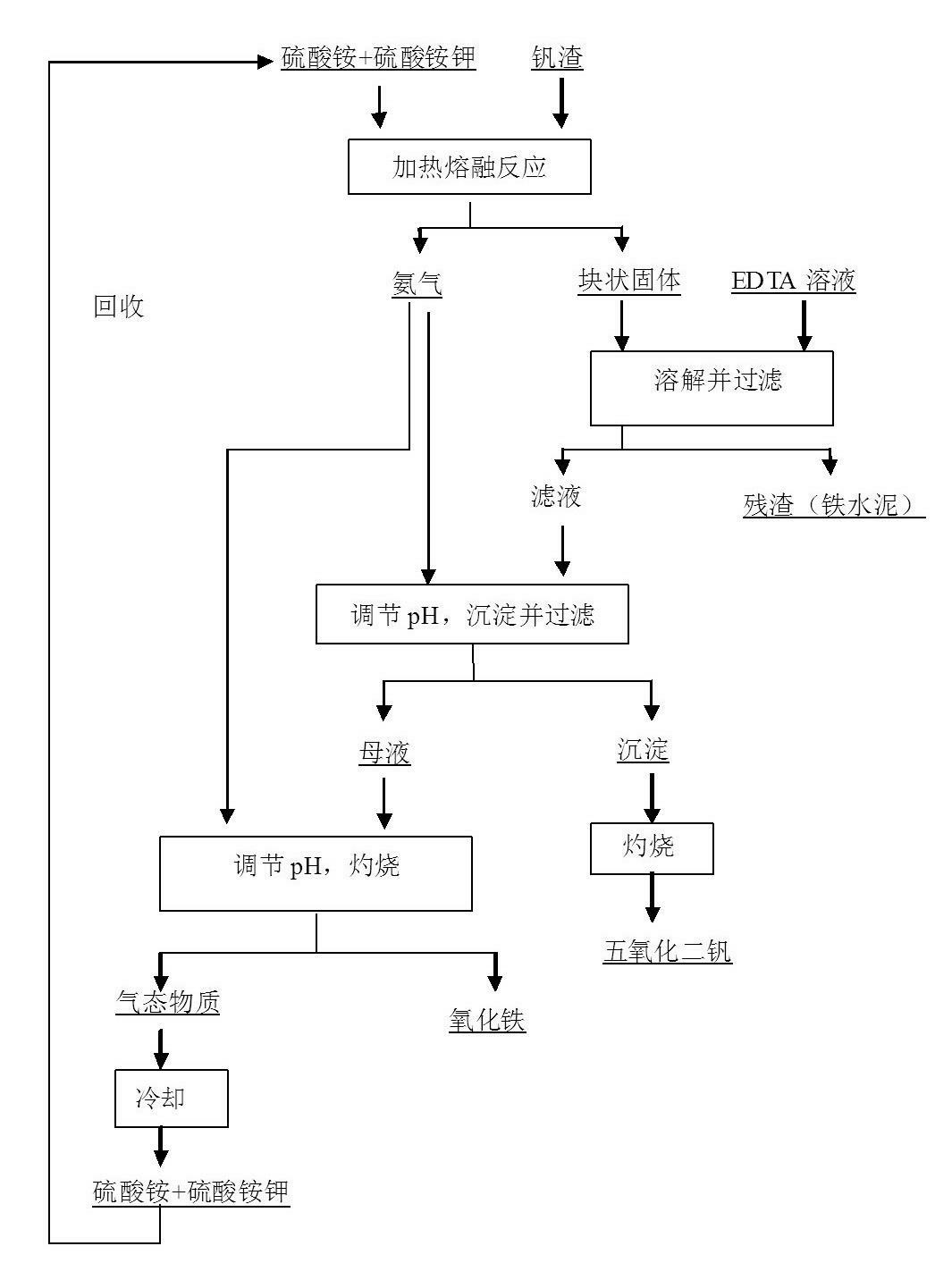

Method used

Image

Examples

Embodiment 1

[0035] (1) Crushing and grinding: the vanadium slag containing 29% by weight of iron and 1.0% by weight of vanadium is crushed and ground to obtain a powder with a diameter of 80 μm;

[0036] (2) Mixing: According to the weight ratio of vanadium slag powder: ammonium sulfate: potassium ammonium sulfate = 1:7:3, weigh the raw materials, and mix the vanadium slag powder with ammonium sulfate and potassium ammonium sulfate evenly;

[0037] (3) Melting: raise the temperature of the above-mentioned mixed material to 300°C and keep it warm for 15 minutes to obtain massive solid and ammonia gas;

[0038] (4) Dissolving and filtering: the block solid obtained above is dissolved in an aqueous solution of EDTA with a concentration of 0.15mol / L, and the molar ratio of EDTA to iron is 0.6:1, and then filtered to obtain the filtrate and residue, the residue is iron cement , the percentage of filtrate water-soluble vanadium accounting for the total weight of vanadium in the vanadium slag is...

Embodiment 2

[0043] (1) Crushing and grinding: the vanadium slag containing 20% by weight of iron and 3.0% by weight of vanadium is crushed and ground to obtain a powder with a diameter of 70 μm;

[0044] (2) Mixing: According to the weight ratio of vanadium slag powder: ammonium sulfate: ammonium potassium sulfate=1:5:5, weigh the raw materials, and mix the vanadium slag powder with ammonium sulfate and ammonium potassium sulfate evenly;

[0045] (3) Melting: raise the temperature of the above-mentioned mixed material to 270°C and keep it warm for 30 minutes to obtain massive solid and ammonia gas;

[0046] (4) Dissolving and filtering: Dissolve the block solid obtained above in an aqueous solution of EDTA with a concentration of 0.18mol / L, and the molar ratio of EDTA to iron is 1.1:1, then filter to obtain the filtrate and residue, the residue is iron cement , the percentage of filtrate water-soluble vanadium accounting for the total weight of vanadium in the vanadium slag is 96%, and ...

Embodiment 3

[0051] (1) Crushing and grinding: the vanadium slag containing 30% by weight of iron and 0.8% by weight of vanadium is crushed and ground to obtain a powder with a diameter of 100 μm;

[0052] (2) Mixing: According to the weight ratio of vanadium slag powder: ammonium sulfate: potassium ammonium sulfate = 1:12:2, weigh the raw materials, and mix the vanadium slag powder with ammonium sulfate and potassium ammonium sulfate evenly;

[0053] (3) Melting: raise the temperature of the above-mentioned mixed material to 400°C and keep it warm for 10 minutes to obtain massive solid and ammonia gas;

[0054] (4) Dissolving and filtering: Dissolve the block solid obtained above in an aqueous solution of EDTA with a concentration of 0.1mol / L, and the molar ratio of EDTA to iron is 0.8:1, then filter to obtain the filtrate and residue, the residue is iron cement , the percentage of filtrate water-soluble vanadium accounting for the total weight of vanadium in the vanadium slag is 93%, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com