Method for preparing contact lens-shaped amniotic dressing

A technology for contact lenses and amniotic membrane dressings, applied in dressings, viscous dressings, ophthalmic treatment, etc., can solve problems such as non-covering of amniotic membrane, displacement of amniotic membrane, and irritation of eyes by hard materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] Embodiment 1: the preparation of amniotic membrane

[0050] (1-1) Preparation of human amniotic membrane

[0051] Human amnion was processed by the method disclosed in the paper by Kim and Tseng (Kim JC and Tseng SC, Cornea, 14:473-84 (1995)). Isolation of amniotic membranes from placentas of pregnant women undergoing caesarean section. Pregnant women were prescreened for viral hepatitis B and C, HIV, and syphilis, and only those placentas with negative maternal blood serology were used. The amniotic membrane thus obtained was successively washed several times with sterile saline solution and sodium hypochlorite, and repeatedly washed with purified water. The obtained membrane is stored under low temperature conditions (2-8° C.) for future use.

[0052] (1-2) Preparation of bovine amniotic membrane

[0053] The bovine amnion was processed through the following steps. Bovine placentas were obtained after parturition, and the amniotic membranes were isolated therefro...

Embodiment 2

[0056] Embodiment 2: the preparation of mold and ring

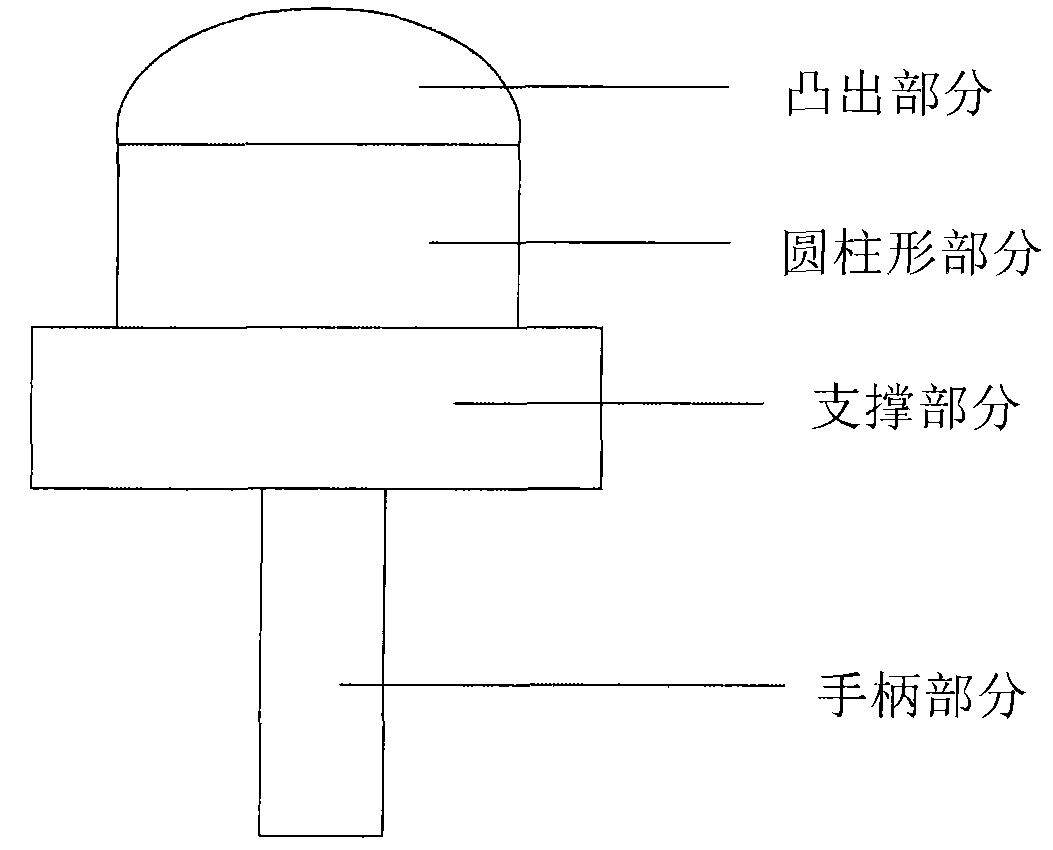

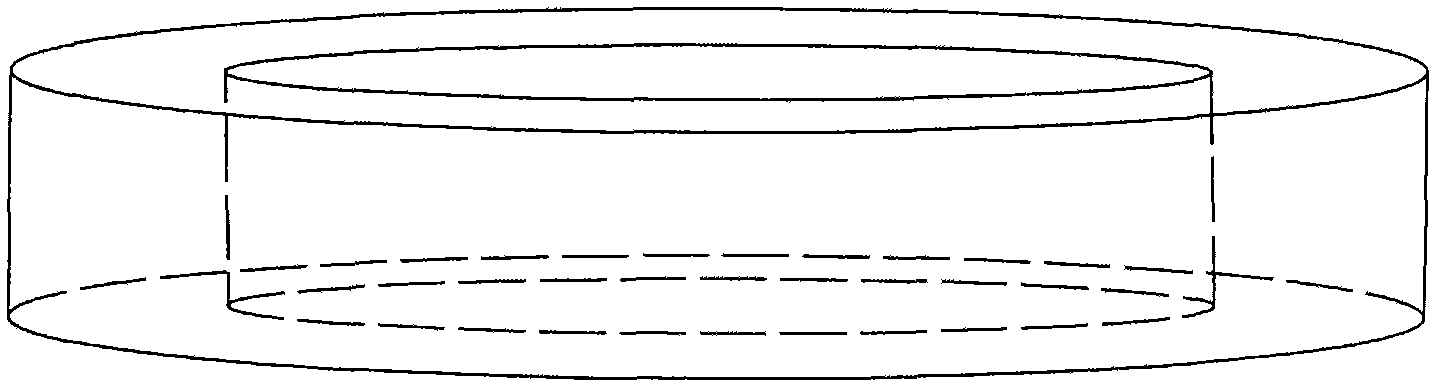

[0057] Such as figure 1 and 2 A mold made to form the amniotic membrane in the shape of a contact lens and a ring (or "O-ring") used to contact the amniotic membrane with the mold are shown. The mold consisted of a cylindrical part with a diameter of 14 mm, a convex part with a base arc of 8.4 to 8.8 mm, a support part and a handle part. The supporting part includes a supporter supporting a ring for contacting and fastening the amniotic membrane, and the handle part has a cylindrical shape connected to the middle of the bottom surface of the supporting part. The mold is made of acetal resin. manufacture figure 2 O-rings to fit each die with a specific base arc. O-rings were made of Teflon (14.1 mm internal diameter) or perfluoroelastomer (12 mm internal diameter).

Embodiment 3

[0058] Example 3: Preparation of Amniotic Membrane

[0059] In order to make the amniotic membrane obtained in (1-1) to (1-3) have a contact lens shape, the amniotic membrane was brought into contact with the contact lens-shaped mold obtained in Example 2, and then fixed on the mold with an O-ring.

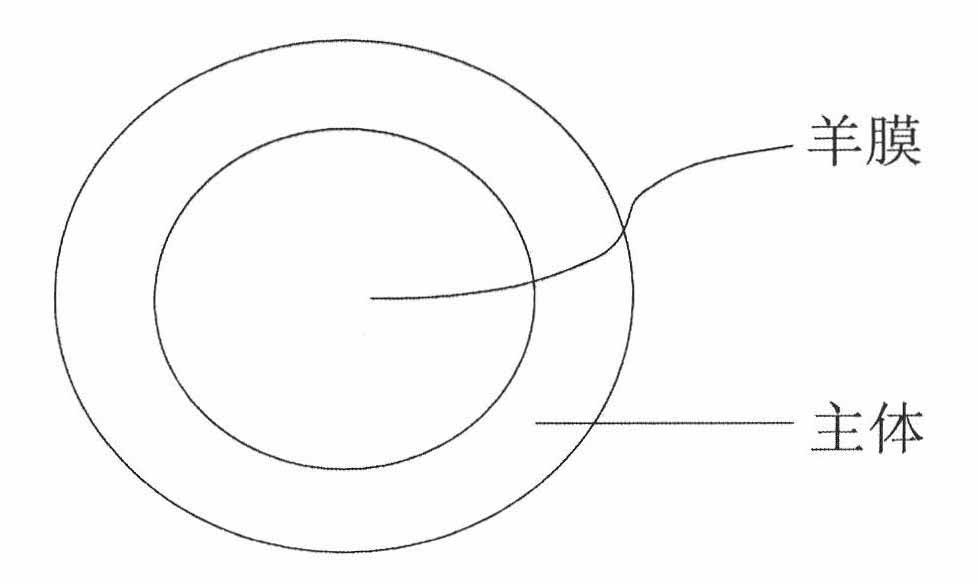

[0060] Specifically, the amniotic membrane was cut to the size of the mold, and then its epithelial layer was in contact with the convex part of the mold ( figure 1 ). In the case of overlapping amniotic membranes, overlap the last layer of amniotic membrane with its epithelial layer facing outwards. Then the O-ring ( figure 2 ) placed on the amniotic membrane or overlapping amniotic membranes to completely cover the mold, and then dried naturally, freeze-dried or vacuum-dried in a clean bench. Top perspective view of dried amniotic membrane (including mold) as image 3 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com