Device for purifying and stirring non-ferrous metal liquid

A non-ferrous metal and stirring device technology, which is applied in the direction of liquid degassing, transportation and packaging, chemical instruments and methods, etc., can solve the problems of high gas consumption of inert gas, high technical parameters of hydrogen removal equipment, and inconvenient maintenance, etc., to achieve The effect of overall performance improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

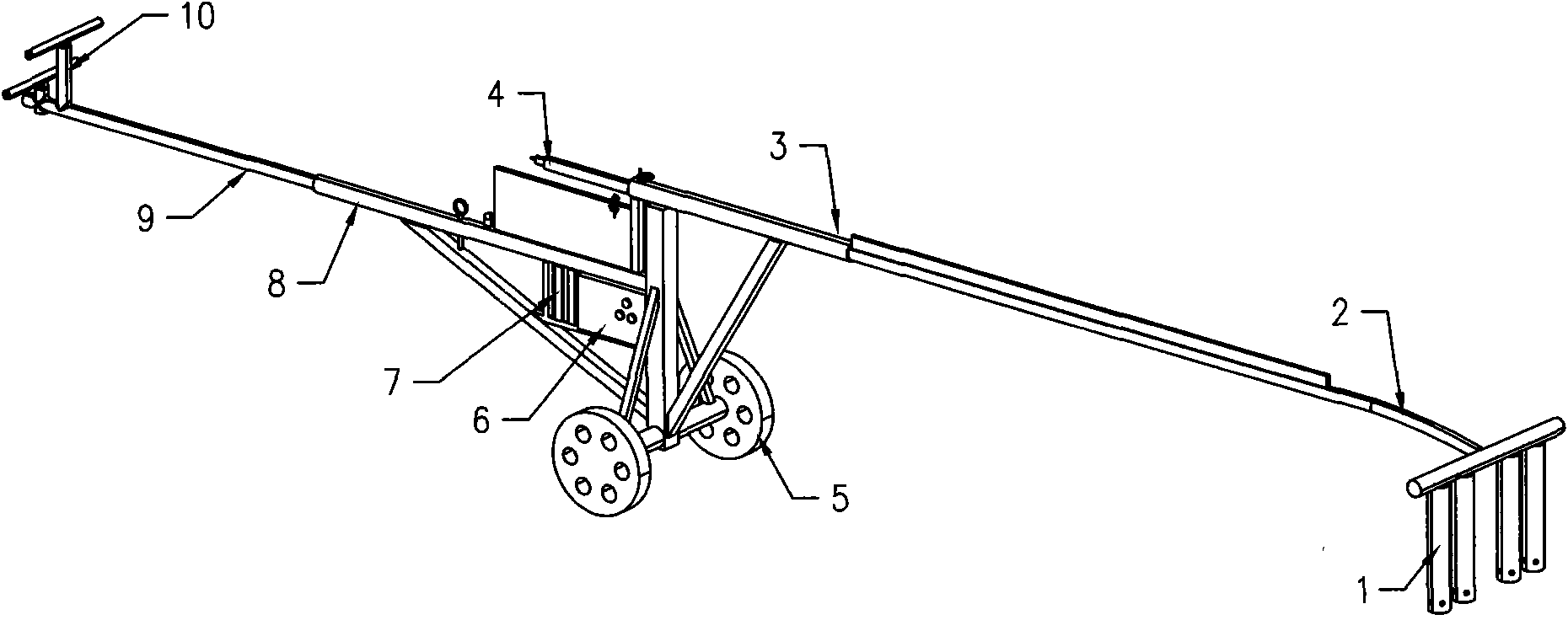

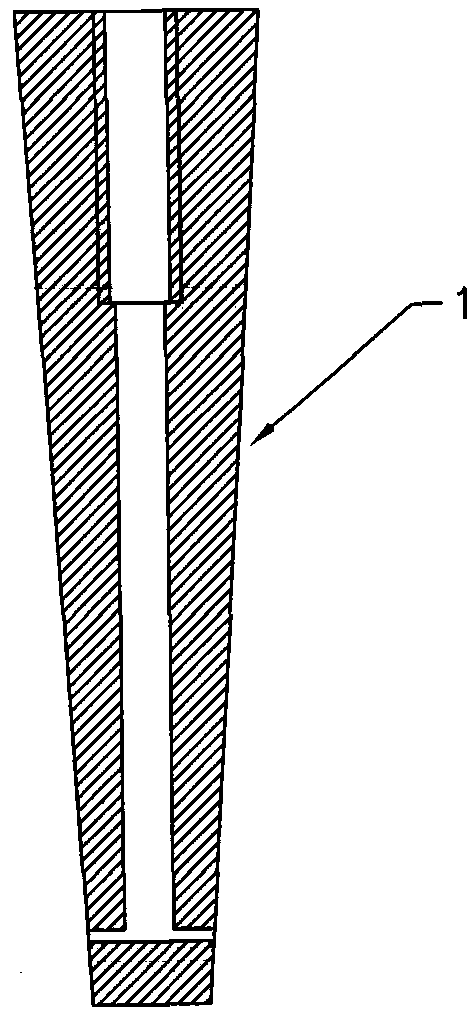

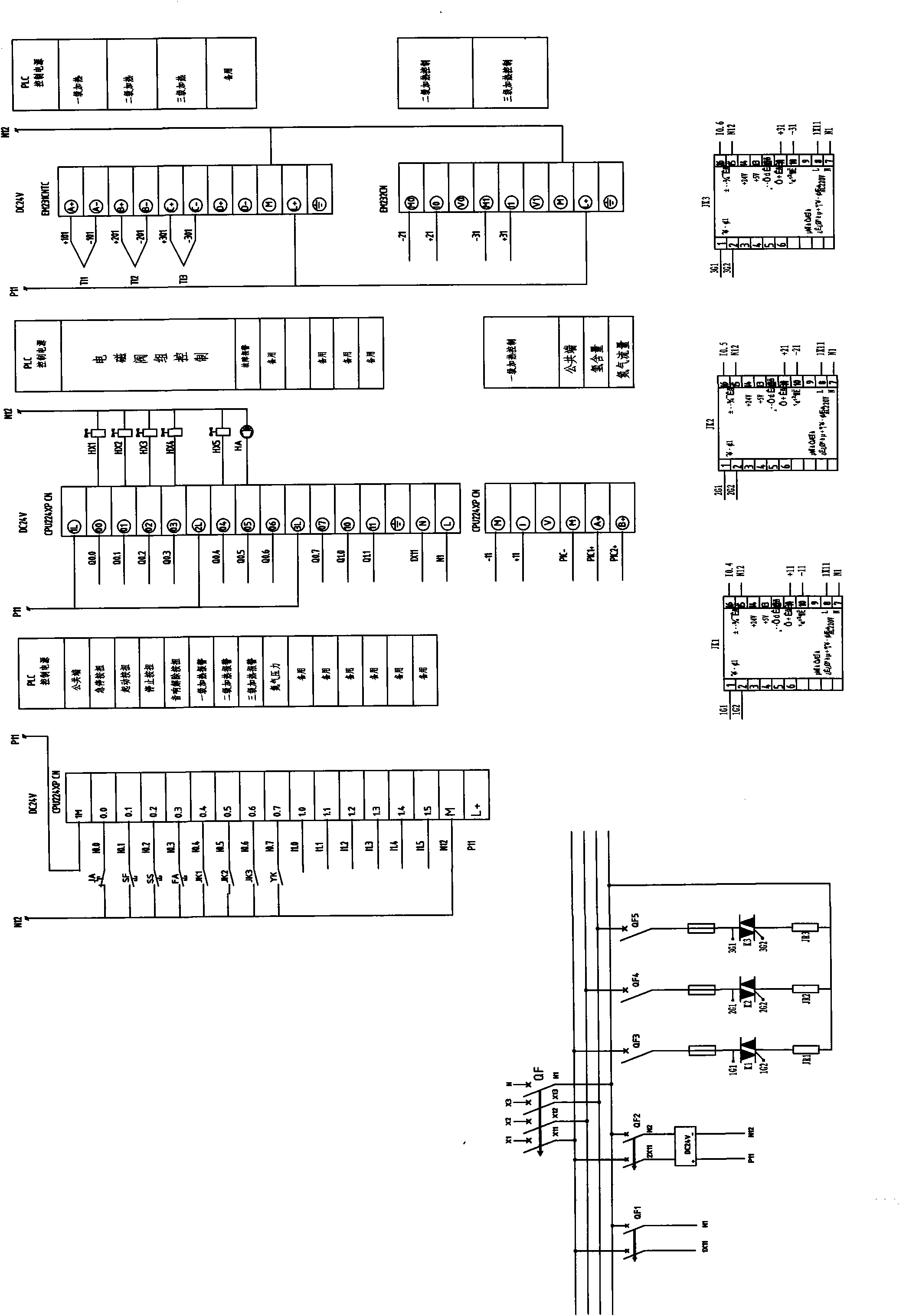

[0019] As shown in the figure, the non-ferrous metal liquid purification and stirring device consists of a bracket (8), a rolling wheel (5) located under the bracket (8), and a handle (10) at the end of the bracket (8). On the bracket (8) A degassing pipe (2) is provided. The end of the degassing pipe (2) is connected with a graphite rod (1) with vent holes. A three-stage heating device is provided on the degassing pipe (2). The number of heating devices can be adjusted according to The setting value of the intake air temperature or the power of the heating device is appropriately increased or decreased, usually one to three levels. The degassing pipe (2) is connected in series with the ventilation control valve group (6), and the ventilation control valve group (6) is composed of two to five vent valves connected in parallel, and there are five in this embodiment. The air inlet (4) of the ventilation control valve group is communicated with the inert gas conduit, and a flow me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com