Acid-containing crude oil demulsifying agent and preparation method thereof

A crude oil demulsifier and demulsifier technology, applied in chemical instruments and methods, chemical dehydration/demulsification, dissolution, etc., can solve problems such as desalination, dehydration and drainage of oil, poor adaptability of crude oil, low demulsification efficiency, etc. , achieve good demulsification, dehydration and desalination, and inhibit emulsification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

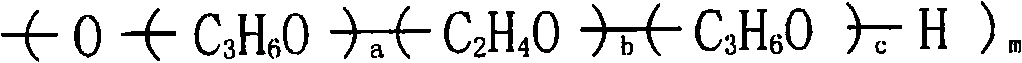

[0031] Example 1 is the composition and preparation method of the acid-containing crude oil demulsifier, and Examples 2 to 4 are the evaluation of the demulsification, desalination and dehydration effect of the acid-containing crude oil by the demulsifier.

[0032] The specific method of demulsifier evaluation is as follows: dilute the demulsifier into a 1% aqueous solution; take 50 g of crude oil and add it to a 100 ml desalting tank, add 2 to 4 ml of water (4 to 8%) and measure the demulsifier; Under the conditions of 800V / cm and 200 times of shaking and mixing, electric desalting was carried out for 30 minutes. After cooling, the salt content and water content of the crude oil were analyzed. The water content analysis is determined by the national standard GB260 method, and the salt content analysis is determined by the national standard GB6532 method.

[0033] Example 1

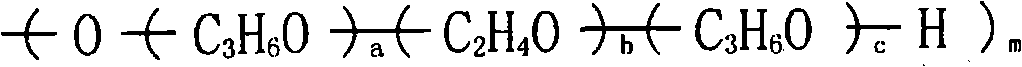

[0034] According to diethylenetriamine: ethylene oxide: propylene oxide weight ratio is 1: 150: 300 t...

Embodiment 2

[0039] Evaluate the effect of demulsifier on demulsification, desalination and dehydration of Shengli high-sulfur and high-acid crude oil. The density of Shengli high-sulfur and high-acid crude oil is 0.944g / cm 3 , the acid value is 2.50 mgKOH / g, the sulfur content is 1.8 (weight) %, and the salt content is 130 mgNaCl / L. The experimental results are shown in Table 2.

[0040] Table 2 Electrode-salting effect of demulsifier on Shengli high-sulfur and high-acid oil

[0041]

Embodiment 3

[0043] Evaluate the effect of desalting agent on demulsification, desalination and dehydration of Brazilian Malim crude oil, the density of Malim crude oil is 0.9336g / cm 3 , the acid value is 2.32 mgKOH / g, the sulfur content is 0.77 (weight) %, and the salt content is 130 NaCl / mg / L. The experimental results are shown in Table 3.

[0044] Table 3 The effect of demulsifier on the electric desalination of Malim crude oil

[0045]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Acid value | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com