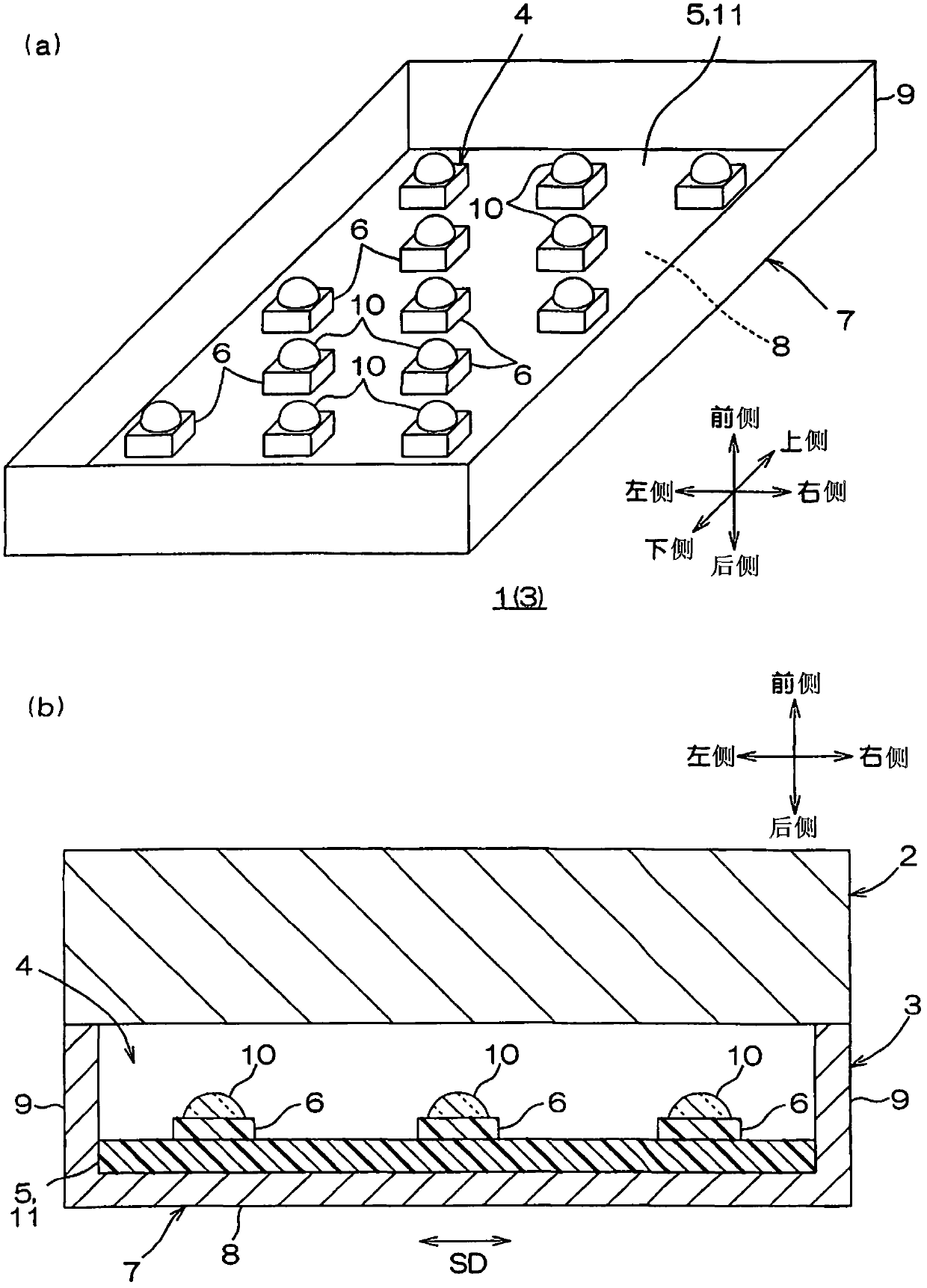

Backlight and liquid crystal display device

A technology of backlight and light source, which is applied in the field of backlight, can solve the problems of uneven color, low thermal conductivity, and insufficient diffusion of liquid crystal display devices, and achieve the effect of improving display performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

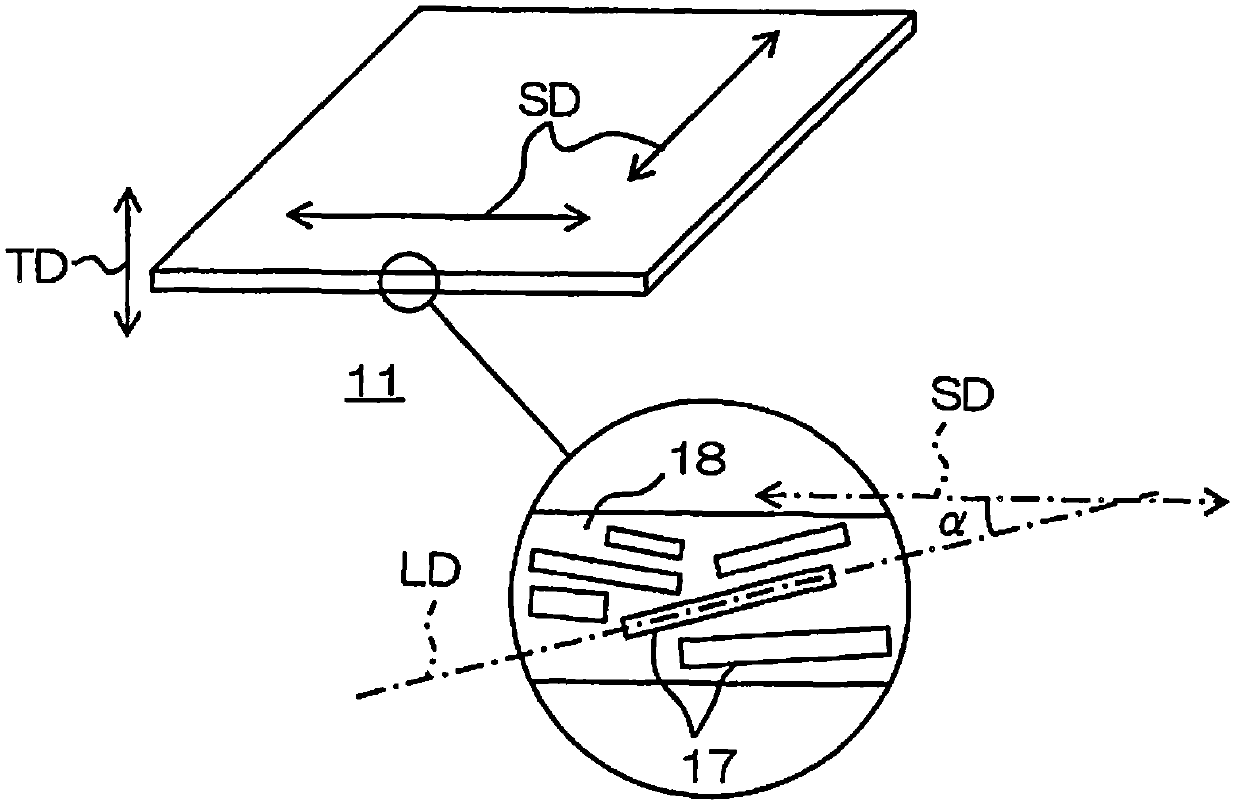

Method used

Image

Examples

Embodiment

[0242] Preparation examples and examples are shown below, and the present invention will be described more specifically, but the present invention is not limited to these examples.

[0243] (Preparation of thermally conductive sheet)

preparation example 1

[0245] 13.42 g of PT-110 (trade name, plate-shaped boron nitride particles, average particle diameter (light scattering method) 45 μm, manufactured by Momentive Performance Materials Japan), 1.0 g of JER828 (trade name, bisphenol A ring Oxygen resin, the first epoxy resin, liquid, epoxy equivalent 184~194g / eqiv., softening temperature (ring and ball method) is less than 25 ℃, melt viscosity (80 ℃) 70mPa·s, Japan epoxy resin company (パパンエキポキシ Resin Co., Ltd.), and 2.0 g of EPPN-501HY (trade name, triphenylmethane type epoxy resin, second epoxy resin, solid, epoxy equivalent 163 to 175 g / eqiv., softening temperature (ring and ball method) 57 ~63°C, manufactured by Nippon Kayaku Co., Ltd.), 3g (solid content 0.15g) (accounting for 5% by mass relative to the total amount of JER828 and EPPN-501H of epoxy resin) curing agent (Curezol2P4MHZ-PW (trade name, Shikoku Kasei) 5% by mass methyl ethyl ketone dispersion (manufactured by the company) was mixed and stirred, and left overnight a...

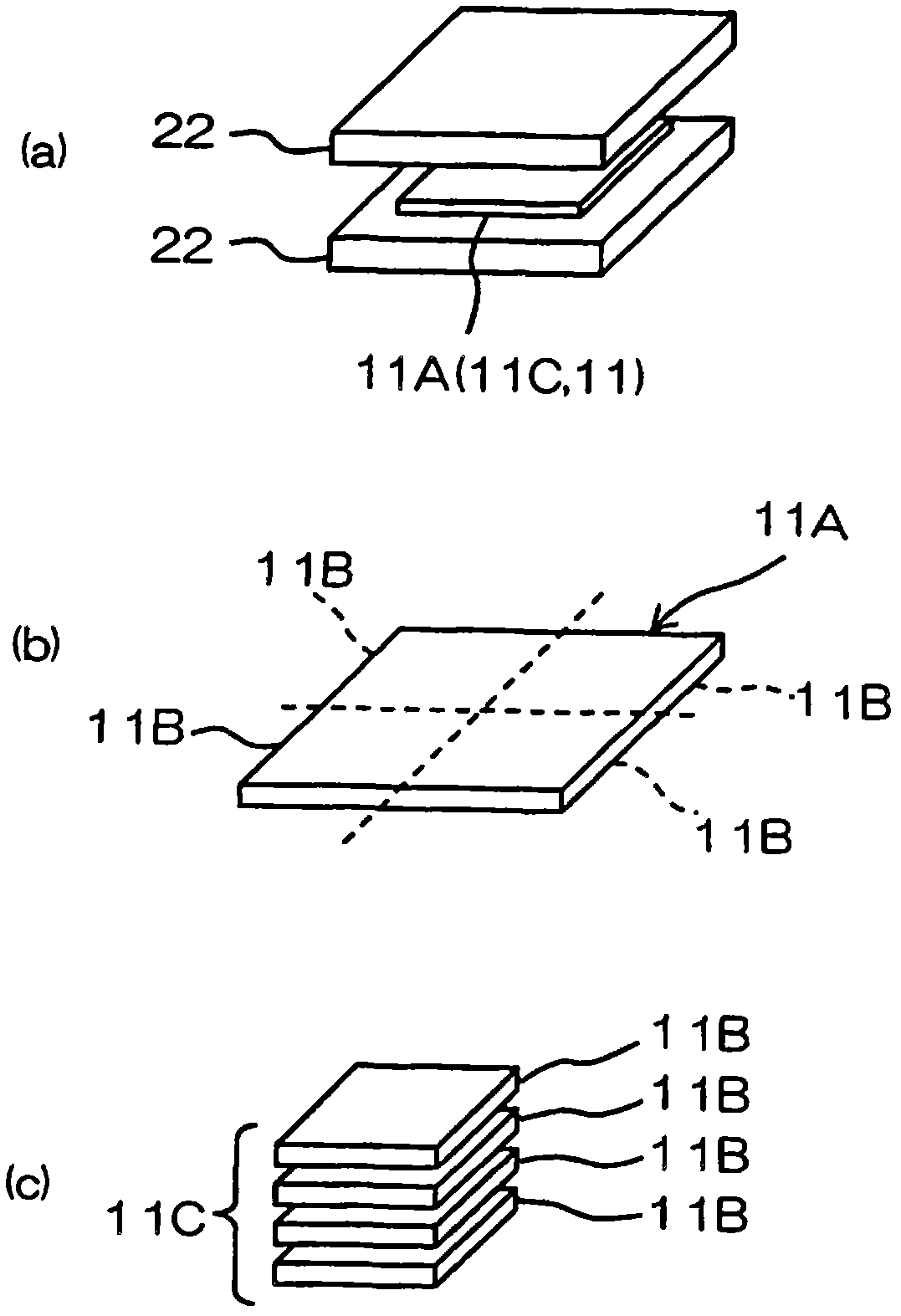

preparation example 2~16

[0252] Based on the compounding ratios and production conditions in Tables 1 to 3, thermally conductive sheets (Preparation Examples 2 to 16) were obtained in the same manner as in Preparation Example 1 (see image 3 ).

[0253] (manufacturing of backlight)

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com