Method for preparing surface phosphorylated water-soluble carbon nanotube and prepared carbon nanotube

A technology of carbon nanotubes and water solubility, which is applied in the field of carbon nanotubes, can solve the problems of poor water solubility of carbon nanotubes, and achieve the effect of simple and easy preparation method, good biocompatibility and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

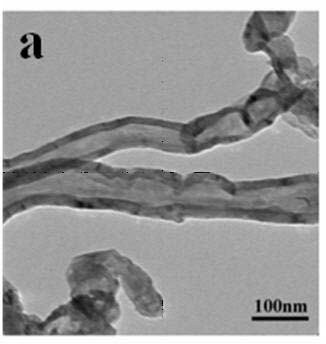

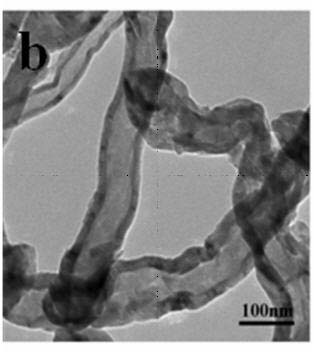

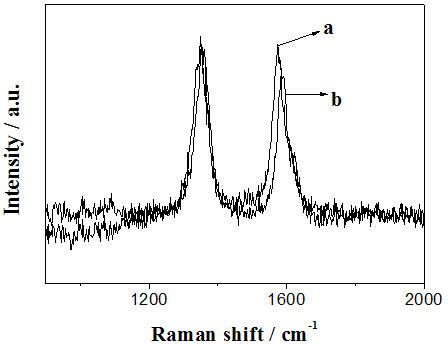

Image

Examples

Embodiment 1

[0032] The carbon nanotubes are purified and calcined as follows:

[0033] (1) Add 100-500 mg MWNTs carbon nanotubes and 10-35 ml concentrated hydrochloric acid (36-38%) into a 50 ml three-necked flask equipped with a reflux condensing device, reflux at 50 °C while magnetic stirring, and react After 5 h, cool to room temperature, add 100 ml of distilled water to dilute, let it stand until the carbon nanotubes are completely precipitated, pour off the supernatant, filter the lower suspension with a microporous membrane, wash with water until the pH of the dripping filtrate=7, A black filter cake of black carbon nanotubes was obtained. Product A was obtained by drying at room temperature.

[0034] (2) Add the product A dried in step 1 and 10-35 ml concentrated nitric acid (65-68%) into a 50 ml three-necked flask equipped with a reflux condensing device, reflux at 50 °C while magnetically stirring, and react 3 After h, cool to room temperature, add 100 ml of distilled water to ...

Embodiment 2

[0038]Take 6.66 mg of treated SWNTs (the treatment method is the same as in Example 1) and dissolve them in 30 ml of distilled water. After ultrasonication for half an hour, add 30 ml of 10 mM benzylidene phosphonic acid with pH=7. The mixture is ultrasonicated for 10 h. After sufficient reaction Filtrate with a microporous membrane, wash with water until clean, and dry at room temperature to obtain phosphonated water-soluble SWNTs.

Embodiment 3

[0040] Take 666 mg of treated MWNTs (the treatment method is the same as in Example 1) and dissolve them in 300 ml of distilled water. After ultrasonication for half an hour, add 30 ml of 10 mM naphthalene-1-methylenephosphonic acid with pH=7, and the mixture is ultrasonicated for 10 h. After fully reacting, filter with a microporous membrane, wash with water until clean, and dry at room temperature to obtain phosphonated water-soluble MWNTs.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com