Antioxidation method of nano copper powder

A nano-copper powder and anti-oxidation technology, which is applied in the anti-oxidation field of nano-copper powder, can solve the problems of powder oxidation and corrosion on the surface of copper powder, etc., and achieve the effect of blocking further corrosion, preventing oxidation, and good anti-oxidation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

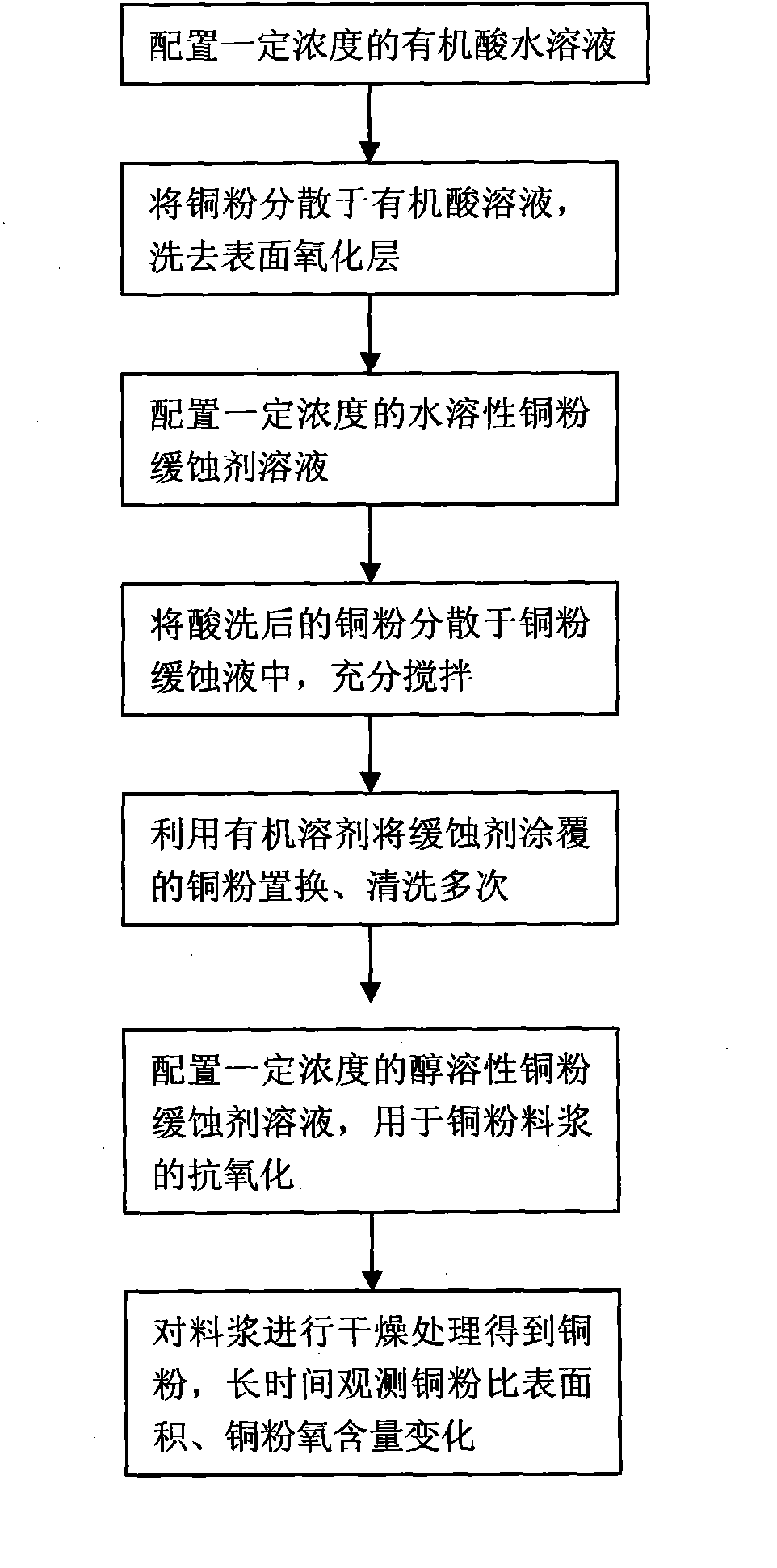

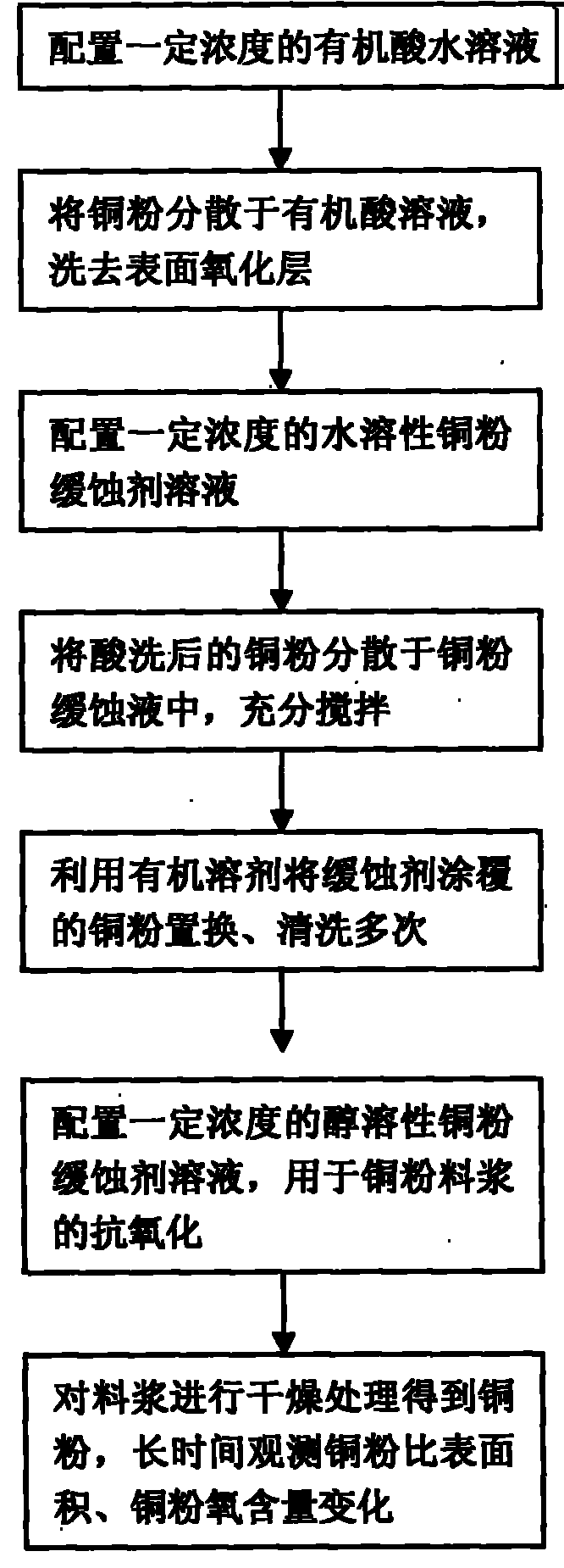

Method used

Image

Examples

Embodiment 1

[0028] (1) Choose citric acid to dissolve in deionized water to prepare a 0.5% citric acid aqueous solution, and the pH of the solution is 2.

[0029] (2) Add the nano copper powder prepared by the PVD method to the above-mentioned citric acid aqueous solution, continue to stir, track the pH value of the solution, and add the citric acid aqueous solution to the slurry in time to maintain the pH value of the solution at 2~2.5 In the meantime, the stirring time is up to 1h and then stand still, and the supernatant liquid is filtered off to obtain copper powder slurry.

[0030] (3) Choose BTA as the copper powder corrosion inhibitor, and configure it as a 0.5% BTA aqueous solution, disperse the copper powder slurry of the above step (2) in it, stir for 1 hour and then stand, and filter the supernatant liquid to obtain copper Powder slurry.

[0031] (4) Use absolute ethanol to replace the copper powder slurry obtained in step (3) three times to obtain a copper powder slurry containing e...

Embodiment 2

[0037] (1) Choose oxalic acid to dissolve in deionized water and prepare an organic acid aqueous solution with a concentration of 0.5%. The pH of the solution is 2.

[0038] (2) Add copper powder to the above organic acid solution, keep stirring, track and measure the pH value of the solution, and add oxalic acid aqueous solution to the slurry in time to maintain the pH value of the solution between 2 and 2.5, and the stirring time is up to 1h After that, let it stand and filter the supernatant.

[0039] (3) Select triethanolamine as the copper powder corrosion inhibitor, and configure it as a 0.5% triethanolamine aqueous solution, disperse the copper powder slurry in it, stir for 1 hour and then stand still, filter the supernatant liquid to obtain copper powder slurry .

[0040] (4) The copper powder slurry was replaced with isopropanol three times to obtain a copper powder slurry containing isopropanol.

[0041] (5) Choose stearic acid as copper powder corrosion inhibitor. First, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com