Composite vacuum heat preservation box for energy storage sodium sulfur battery module

A technology of thermal insulation box and sodium-sulfur battery, which is applied in thermal insulation containers, packaging and application under vacuum/special atmosphere, etc., can solve the problems of increasing thermal insulation layer, failure temperature field of thermal insulation box, and reduction of effective use space of thermal insulation box, etc. Achieve good thermal insulation performance, solve the effect of heat unevenness or heat loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

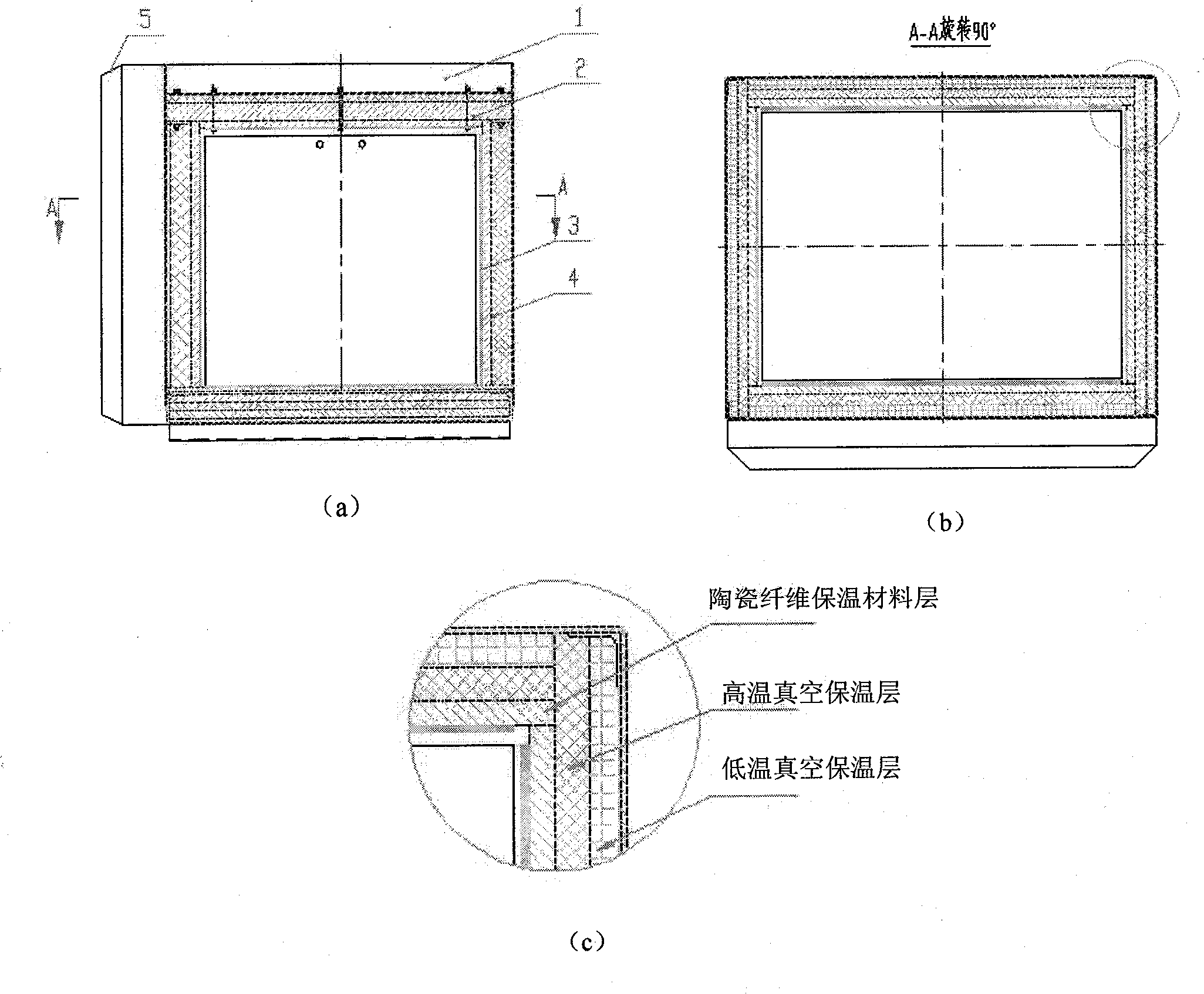

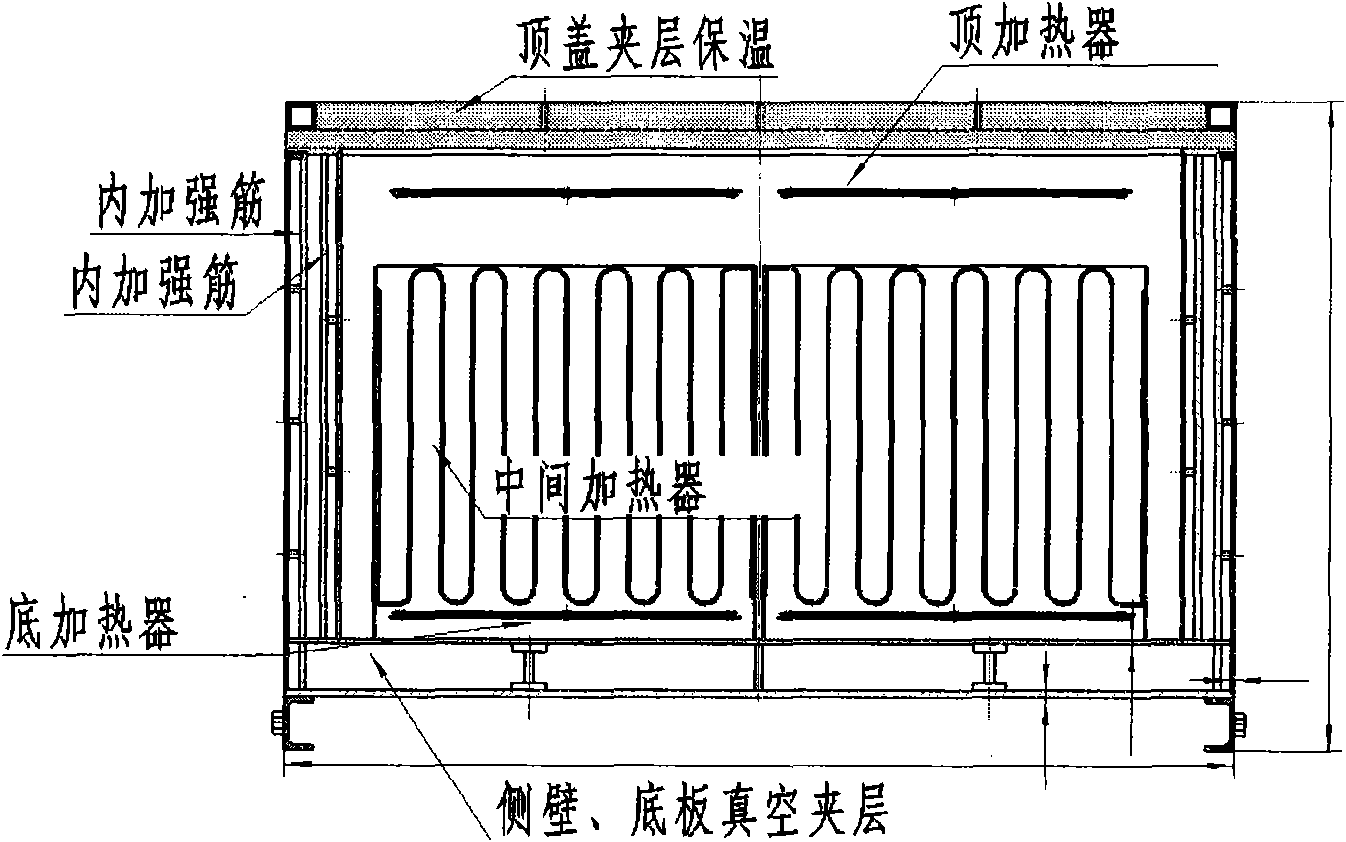

Embodiment 1

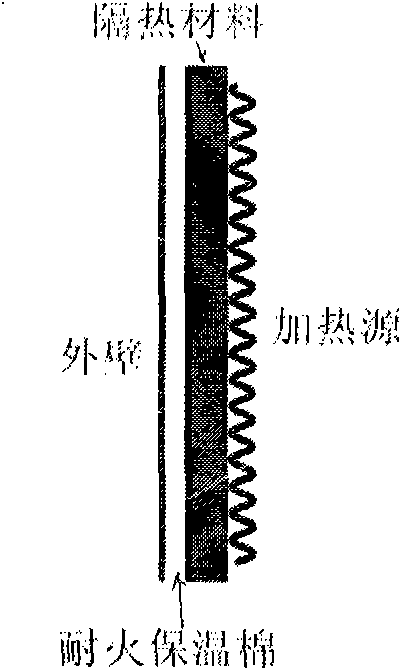

[0032] image 3 A composite vacuum-type incubator made according to the present invention with an outer dimension of 1070×1010×980mm is provided. The exterior of the incubator adopts a stainless steel structure, and the insulation layer of the incubator is a reflective layer, a heat-insulating layer, and a vacuum layer from the inside to the outside. , The total thickness of the insulation layer is 7cm, and the constant temperature power is <300W. There are a designed number of large-capacity sodium-sulfur single batteries inside the incubator, and a certain amount of quartz sand is filled in the gaps between the sodium-sulfur batteries. The temperature field inside the incubator is placed near the battery, and placed and tested evenly according to the upper and middle lower parts of the incubator. There are 6 temperature measurement points in the upper part and 8 temperature measurement points in the middle and lower part. After the incubator reaches the working temperature,...

Embodiment 2

[0034]According to the composite vacuum-type incubator with an outer dimension of 1570×1010×1180mm made according to the present invention, the outside of the incubator adopts a stainless steel structure, and the insulation layer of the incubator is a reflection layer, a heat insulation layer, a vacuum layer, and an insulation layer from the inside to the outside. The total thickness is 7cm, constant temperature power <500W. There are a designed number of large-capacity sodium-sulfur single batteries inside the incubator, and a certain amount of quartz sand is filled in the gaps between the sodium-sulfur batteries. The temperature field inside the incubator is placed near the battery, and placed and tested evenly according to the upper and middle lower parts of the incubator. There are 6 temperature measurement points in the upper part and 8 temperature measurement points in the middle and lower part. After the incubator reaches the working temperature, the actual measured hig...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com