Technology for continuously producing hydrazine hydrate

A hydrazine hydrate and process technology, which is applied in the field of continuous production of hydrazine hydrate, can solve the problems of high energy consumption and material consumption, large equipment investment, high environmental protection pressure and the like, and achieves the effects of small investment and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

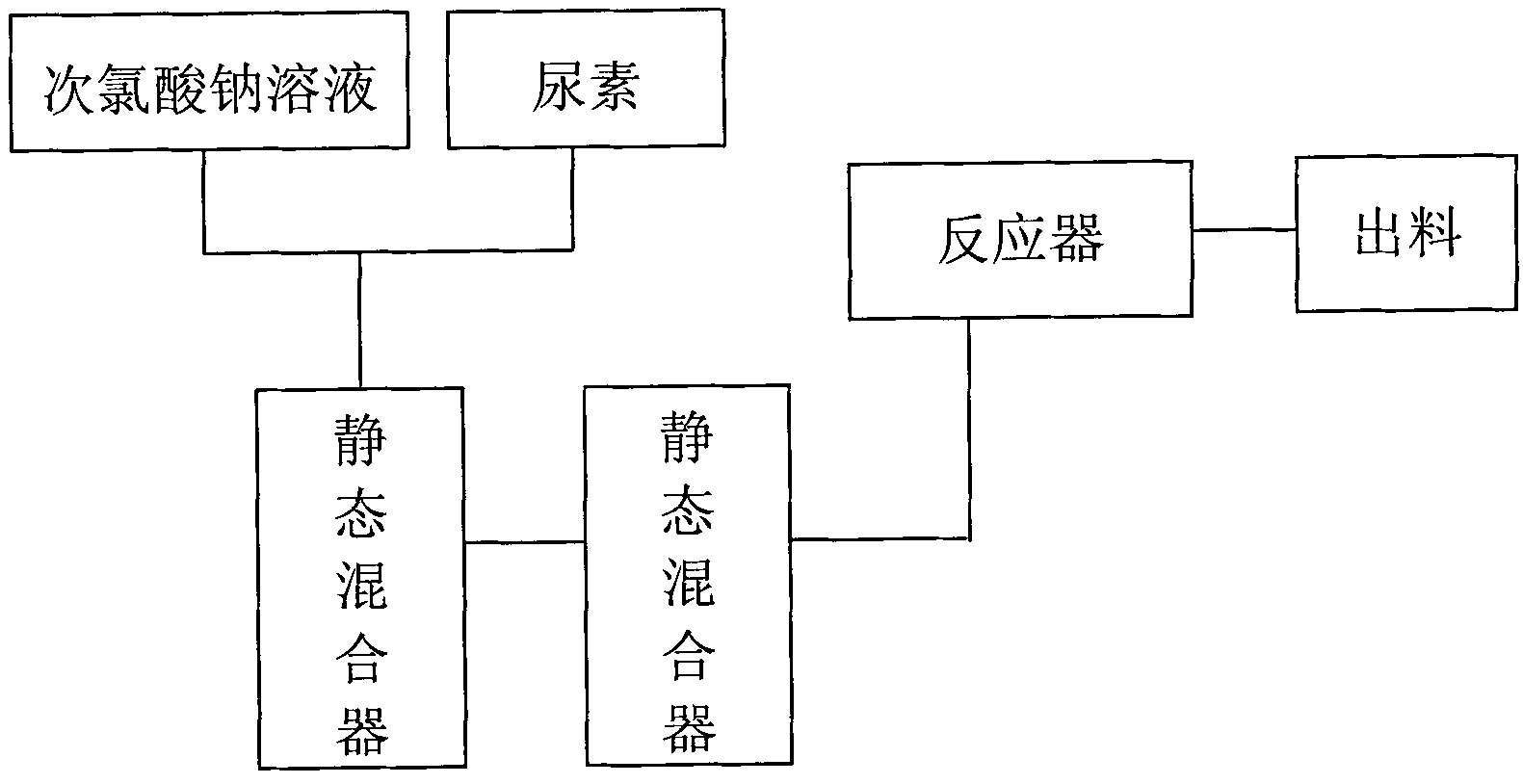

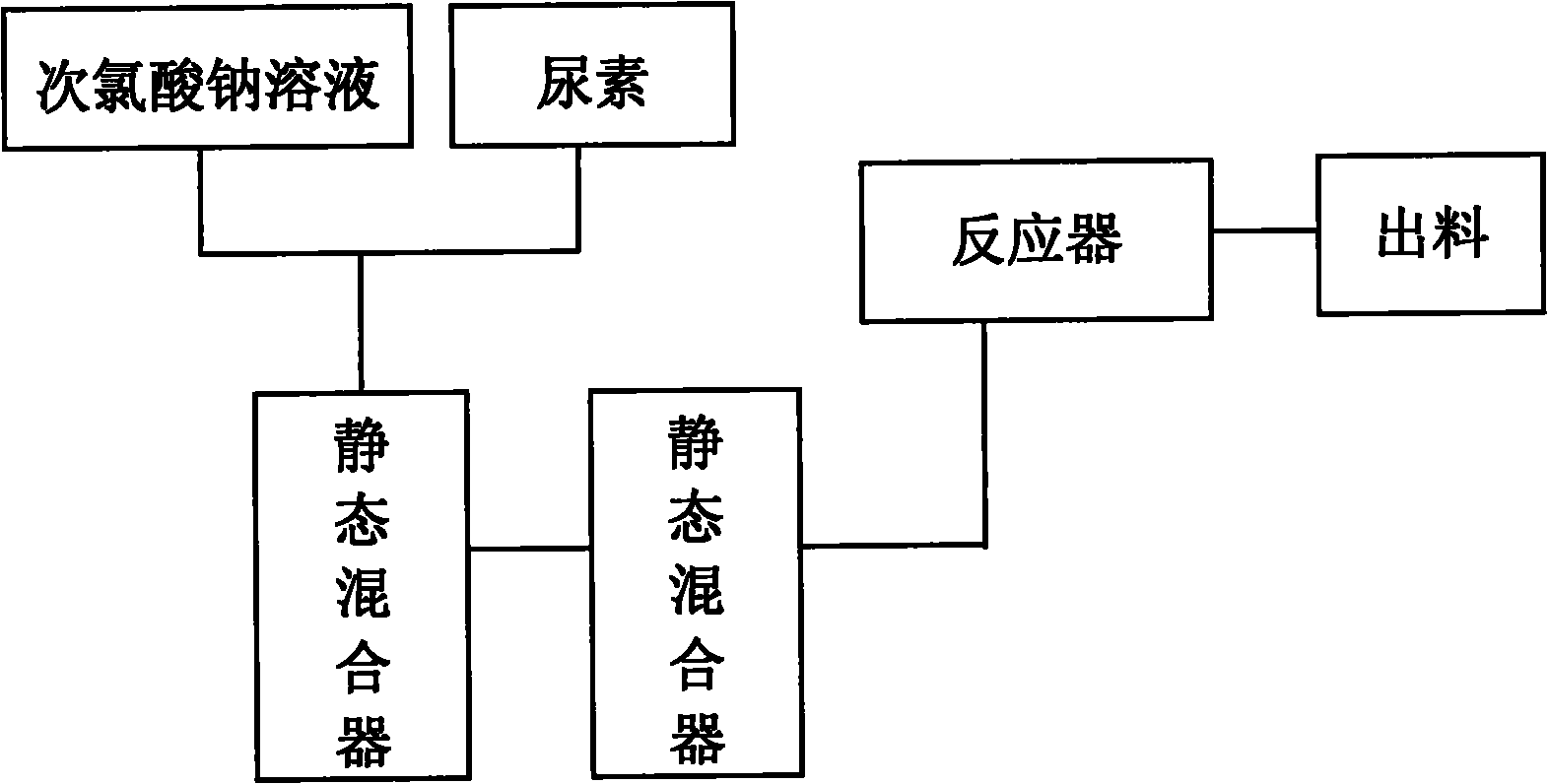

Method used

Image

Examples

Embodiment 1

[0030] First, pass chlorine gas into the 25% sodium hydroxide solution to prepare a sodium hypochlorite solution with an available chlorine concentration of 120g / L and a free alkali concentration of 150-160g / L. Weigh 5kg of urea and add 17L of water to prepare a solution ,, and open the frozen brine inlet and outlet of the static mixer to maintain a constant temperature of 20°C. Add urea and sodium hypochlorite into the reactor and keep stirring. After 30 minutes, open the outlet of the reactor to allow the materials to enter the reactor, heat the reactor quickly until the temperature rises to 125°C, and the materials are discharged from the reactor. The detected yield of hydrazine hydrate is 85%.

Embodiment 2

[0032] First, pass chlorine gas into the 25% sodium hydroxide solution to prepare a sodium hypochlorite solution with an available chlorine concentration of 120g / L and a free alkali concentration of 150-160g / L. Weigh 5kg of urea and add 17L of water to prepare a solution ,, and open the frozen brine inlet and outlet of the static mixer to maintain a constant temperature of 20°C. Add urea and sodium hypochlorite into the reactor and keep stirring. After 40 minutes, open the outlet of the reactor to allow the materials to enter the reactor, heat the reactor quickly until the temperature rises to 125°C, and the materials are discharged from the reactor. The detected yield of hydrazine hydrate was 87%.

Embodiment 3

[0034] First, chlorine gas is introduced into a sodium hydroxide solution with a concentration of 25% to prepare a sodium hypochlorite solution with an available chlorine concentration of 120g / L and a free alkali concentration of 150-160g / L. Weigh 5kg of urea and add 17L of water to prepare Solution, and open the inlet and outlet of the frozen brine of the static mixer to maintain a constant temperature of 20°C. Add urea and sodium hypochlorite into the reactor and keep stirring. After 60 minutes, open the outlet of the reactor to allow the materials to enter the reactor, heat the reactor quickly until the temperature rises to 125°C, and the materials are discharged from the reactor. The detected yield of hydrazine hydrate is 90%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com