Method for extracting active ingredients from tangerine seeds

A technology for active ingredients and orange pits, applied in the field of extraction and separation of active ingredients of natural products, can solve the problems that the extraction and purification process needs to be perfected, the extraction method goes against objective facts, the yield of limonin is low, and the like, so as to avoid flammability. Explosive problem, short extraction time, high yield effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

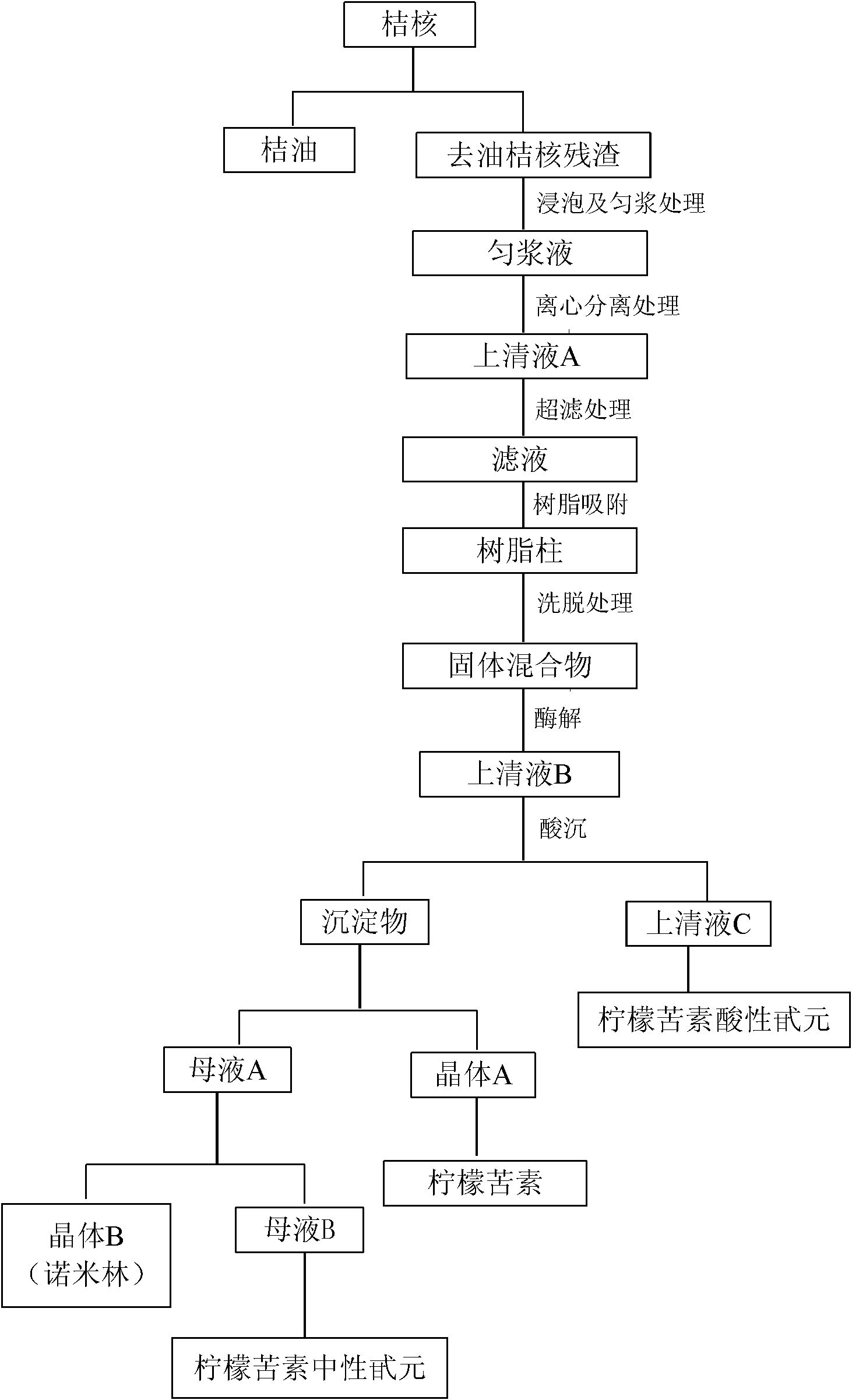

[0071] A method for extracting active ingredients from tangerine stones, specifically comprising the following steps:

[0072] The first step: extract the orange oil after crushing the orange core:

[0073] After 42.74g orange core is pulverized to 60 orders, join in supercritical carbon dioxide extractor and extract orange oil, set carbon dioxide gas pressure as 30MPa, extraction temperature is 48 ℃, extraction time is 1.5 hours, obtains orange oil 17.74g and de-orange orange Nuclear residue 24.98g.

[0074] The second step: remove the oil orange pit residue and soak and homogenate:

[0075] According to the ratio of liquid to solid ratio of 10ml / g, use distilled water to soak to remove oil orange core residues, and adjust the pH value to 8 with a NaOH solution with a concentration of 3M. After soaking for 0.5h at a temperature of 80°C, use a flash extractor. For homogenization treatment, the rotation speed is 3500r / min, stirring and crushing for 3min, and a homogenate liqu...

Embodiment 2

[0092] The difference between this example and Example 1 is that it includes the process of preparing limonin acidic aglycone, specifically:

[0093] Dry the supernatant C obtained by centrifuging in the eighth step under reduced pressure. The drying conditions under reduced pressure are 0.08MPa and 80°C to obtain the crude limonin acid aglycone, which is then extracted with methanol and evaporated at 40°C. Methanol was recovered to obtain 0.21 g of limonin acid aglycone as the extract.

Embodiment 3

[0095] The difference between this embodiment and Example 2 is that it also includes the steps of preparing nomilin and limonin neutral aglycone, specifically:

[0096] Evaporate the mother liquor A in the ninth step to dryness to obtain a dry product, add methanol (analytical pure) to the dry product according to the ratio of liquid to solid ratio of 15ml / g, then stand at -20°C for 0.5h, and centrifuge at 4000r / min for 10min , the precipitate obtained is crystal B, the supernatant is mother liquor B, and the crystal B is 0.036 g of nomilin. .

[0097] After the mother liquor B was evaporated to dryness, the crude limonoid neutral aglycone was obtained, and NaOH with a pH value of 10 was added to the crude limonoid neutral aglycone at a liquid-solid ratio of 8ml / g, and heated to 60 ℃ to dissolve the crude limonin neutral aglycone in NaOH solution with a pH value of 10, and then use 4M hydrochloric acid to adjust the pH of the solution to 1.5, centrifuge, and wash the obtained...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com