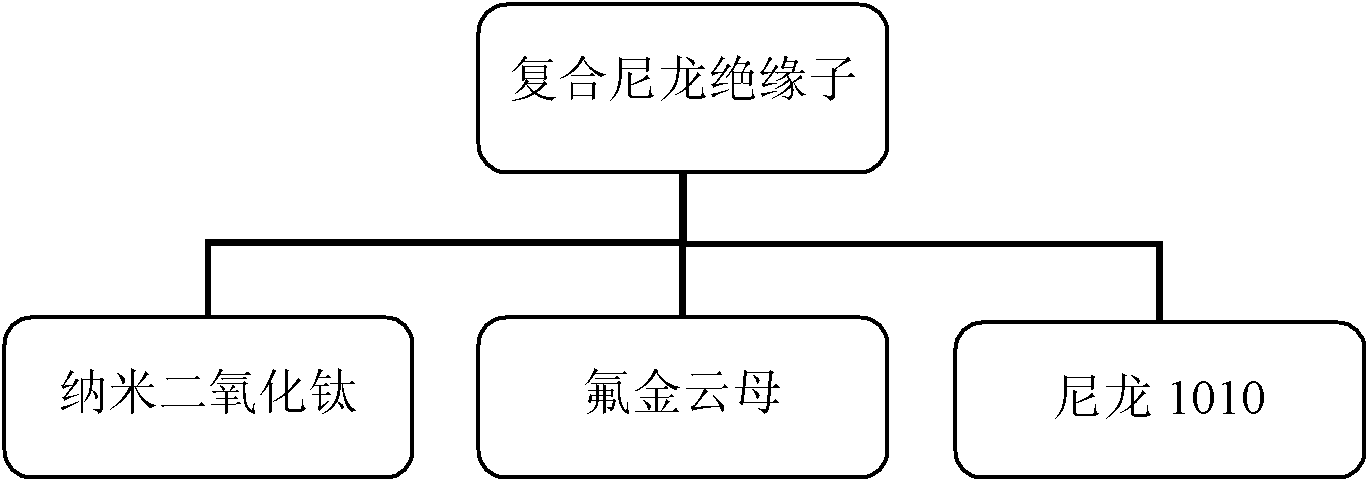

Composite insulating material and preparation method of composite insulating material

A composite insulation and mixed powder technology, applied in organic insulators, plastic/resin/wax insulators, etc., can solve the problems of high water absorption, insufficient modulus and strength, and harsh technological conditions of nylon 1010 insulators, and achieve low surface The effect of secondary electron emission coefficient, low cost and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

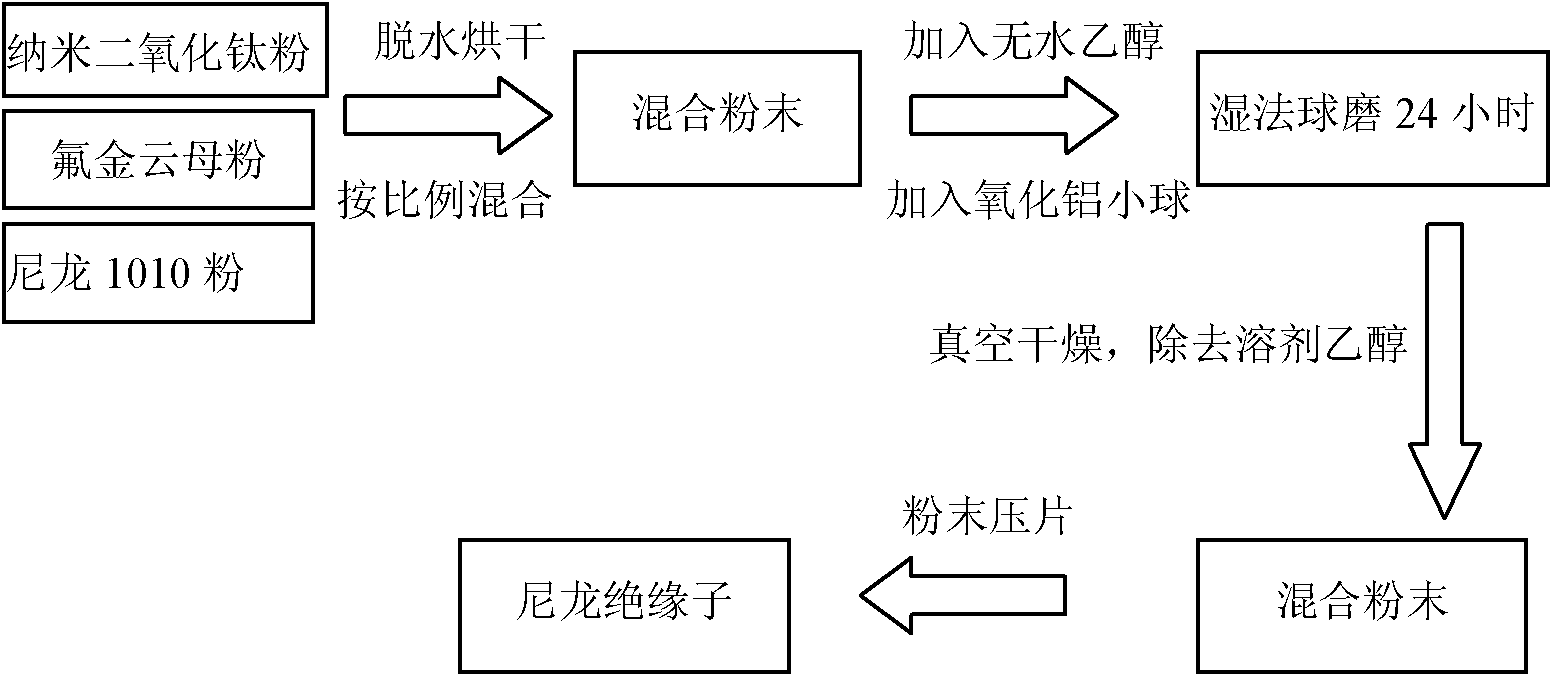

[0032] Nylon 1010 powder, nano-titanium oxide powder, and fluorphlogopite powder were dehydrated and dried at 110°C for 5 hours, respectively, and then mixed according to the mass percentage of 66%: 25.5%: 8.5%, and a certain amount of anhydrous Ethanol and alumina ceramic balls (about 4mm in diameter) were put into a ball mill for wet ball milling for 24 hours. After the ball milling, the mixed system was put into a vacuum oven at 80°C for 10 -1 Pa vacuum degree, 6 hours, solvent ethanol is completely volatilized, obtains the mixed powder of nylon 1010-nanometer titanium dioxide-fluorine phlogopite that mixes well.

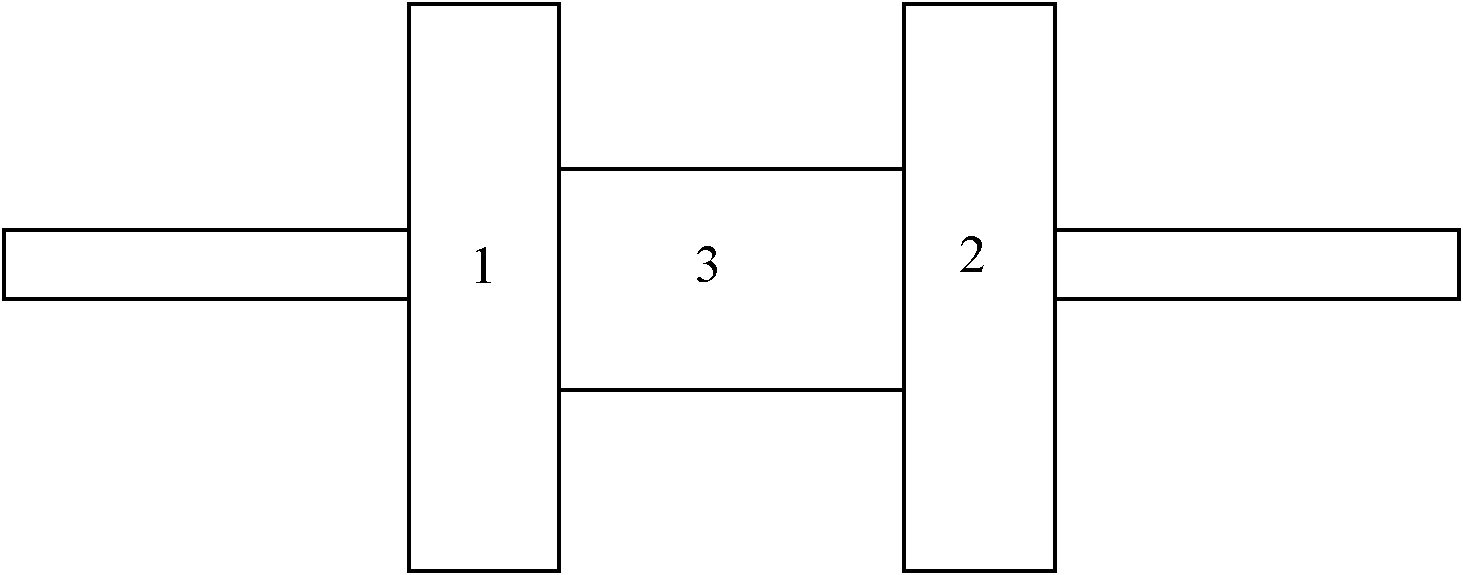

[0033] Put the mixed powder into an electric heating mold, and press it into an insulator with a certain shape with a powder tablet press. When the powder is pressed into tablets, the heating temperature is controlled at 240°C, and the pressure is 3Mpa. When pressing each time, the pressure is maintained and cooled to 190°C, and then the pressure is released to z...

Embodiment 2

[0036] The preparation process was the same as in Example 1, except that the mass percent ratio of nylon 1010 powder, nano-titanium dioxide, and fluorphlogopite powder was 66.5%:30%:3.5%, and the pressure was 5Mpa when the powder was pressed into tablets.

[0037] The flashover voltage of the pressed sample is higher than that of the comparison sample pressed from pure nylon 1010 powder. The data are shown in Table 1.

Embodiment 3

[0039] The preparation process was the same as in Example 1, except that the mass percent ratio of nylon 1010 powder, nano-titanium dioxide, and fluorphlogopite powder was 72.5%: 20%: 7.5%, and the pressure when the powder was pressed into tablets was 4Mpa.

[0040] The flashover voltage of the pressed sample is higher than that of the comparison sample pressed from pure nylon 1010 powder. The data are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com