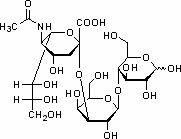

Preparation method of 3'-sialic acid lactose

A technology of sialyllactose and lactose, which is applied in the field of bioengineering, can solve the problems that the simulated human milk effect cannot be satisfied, and the difference is large.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Example 1 Fermentation

[0024] (1) High-density culture: use Escherichia coli CCTCC NO: M208088 as the strain, add 18L of fermentation medium to a 30L fermenter with an inoculum of 4%, maintain the temperature at 30-37°C throughout the fermentation process, and ventilate at 1- 1.5 vvm, the stirring speed is 600-800 r / min; during the fermentation process, ammonia water is added to control the pH to 6-7, and the fermentation cycle is 32-48 hours; after 2-6 hours of fermentation, feed medium is added until the end of fermentation The addition was stopped half an hour before, and the volume of the added feed medium was equivalent to the volume of the fermentation medium, and was added to the fermentation system at an even speed.

[0025] Fermentation medium composition g / L: sorbitol 30, lactose 20, ammonium sulfate 2.5, dipotassium hydrogen phosphate trihydrate 2.5, MgSO 4 0.9, tryptone 1.5.

[0026] Feed medium composition g / L: sorbitol 400, ammonium sulfate 50.

[00...

Embodiment 2

[0028] The collection of embodiment 2 sialyllactose

[0029] (1) Sterilization by centrifugation: After the fermentation, the fermented liquid obtained in Example 1 was heated at 80°C for 30 minutes, and then centrifuged at 6000 rpm for 10 minutes to remove bacteria, and supernatant 1 containing sialyllactose and bacteria sludge were obtained.

[0030] (2) Heating and lysing the bacteria: Dilute the bacteria slime obtained in step (1) with water 3 to 5 times, heat in a boiling water bath for 45 minutes, and then centrifuge at 10,000 rpm for 10 minutes to remove cell debris to obtain supernatant 2 containing sialyllactose;

[0031] (3) Ion exchange resin adsorption and desorption: Combine the supernatant 1 obtained in step (1) and the supernatant 2 obtained in step (2), heat to 80-90°C, and heat at constant temperature for 15 minutes; The membrane is subjected to ultrafiltration to collect the filtrate; the filtrate is treated with a molecular weight cut-off of 500Da ultrafiltr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com