Substrate for surface enhanced Raman scattering and preparation method thereof

A technology that enhances Raman scattering and substrates, applied in the field of chemical analysis and detection, to achieve the effects of improved sensitivity, easy concentration, and small contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0061] The present invention also provides a method for preparing a substrate for surface-enhanced Raman scattering, comprising:

[0062] a) sintering the solid support with zinc acetate on the surface at 300-350°C to obtain the first slide;

[0063] b) soaking the first slide in a mixed solution of zinc nitrate, hexamethylenetetramine and 1,3-propanediol to form a zinc oxide nanolayer on the surface of the first slide to obtain a second slide ;

[0064] c) soaking the second slide in the noble metal solution, taking it out and irradiating it with ultraviolet light to obtain a third slide;

[0065] d) immersing the third slide in a noble metal plating solution to form a noble metal nanolayer on the surface of the zinc nanolayer; the noble metal is gold or silver;

[0066] e) soaking the fourth slide in a hydrophobic compound solution to form a hydrophobic layer on the surface of the noble metal nanoparticle layer of the fourth slide to obtain a substrate.

[0067] Compared ...

Embodiment 1

[0075] Preparation of superhydrophobic surface-enhanced Raman scattering substrate

[0076] Take a glass slide with a size of 1 cm×1.5 cm, and ultrasonically clean it in acetone, ethanol, and ultrapure water for 10 minutes in order to obtain a clean glass slide, and dry it with nitrogen. Wet the slide with 12 μL, 0.005M ethanol solution of zinc acetate, rinse with ethanol after 25 seconds, N 2 Blow dry and repeat this operation 4 times. The glass slide was placed in a muffle furnace and sintered at 350° C. for 20 min to obtain a glass slide coated with ZnO seeds. Put the glass slide covered with ZnO into 20mL containing 0.025MZn(NO 3 ) 2 , 0.025M HMT, and 0.19M DAP solution, reacted at 92°C for 90min, and prepared a glass slide coated with ZnO nanorod array. Put the glass slide coated with ZnO nanorod array into 3mL 0.05M AgNO 3 Soak in the solution for 30 minutes, and then turn on the ultraviolet lamp for 10 minutes. The wavelength of the ultraviolet lamp is 254nm, the p...

Embodiment 2

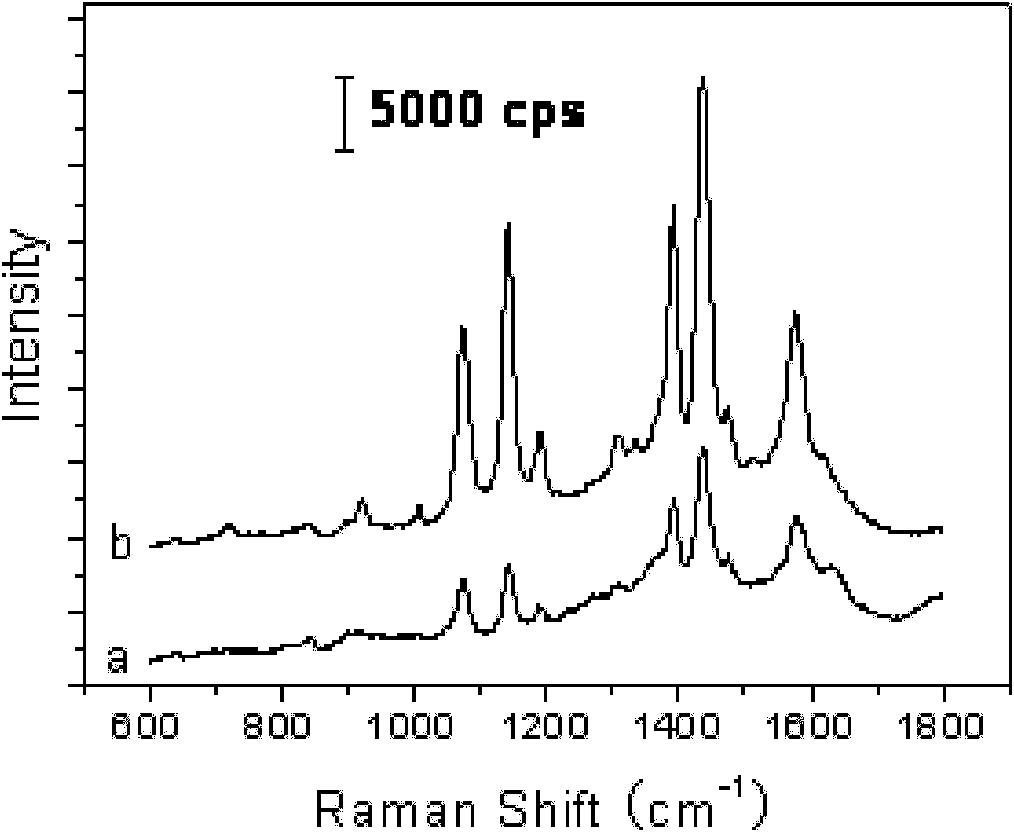

[0082] Take 1×10 -6 5 μL of 4-ATP (p-mercaptoaniline) aqueous solution of M was dropped on the substrate prepared in Example 1, and dried at room temperature. After the solvent evaporated, the substrate was placed in a Renishaw 2000 microscope. The Raman scattering spectrum data is collected in the laser Raman spectrometer, and the results are as follows figure 1 Shown in curve b.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com