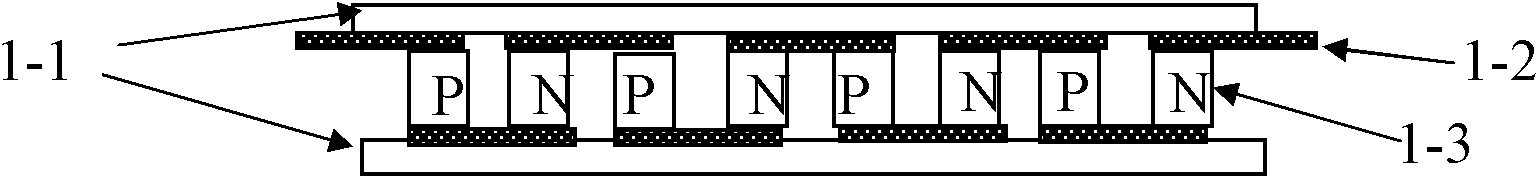

Method for manufacturing heat-resisting temperature differential thermoelectric component

A technology of thermoelectric devices and manufacturing methods, which is applied in the direction of manufacturing/processing of thermoelectric devices, can solve problems such as high-temperature melting of solder joints, device failure, etc., and achieve the effect of increasing the use temperature and high application value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

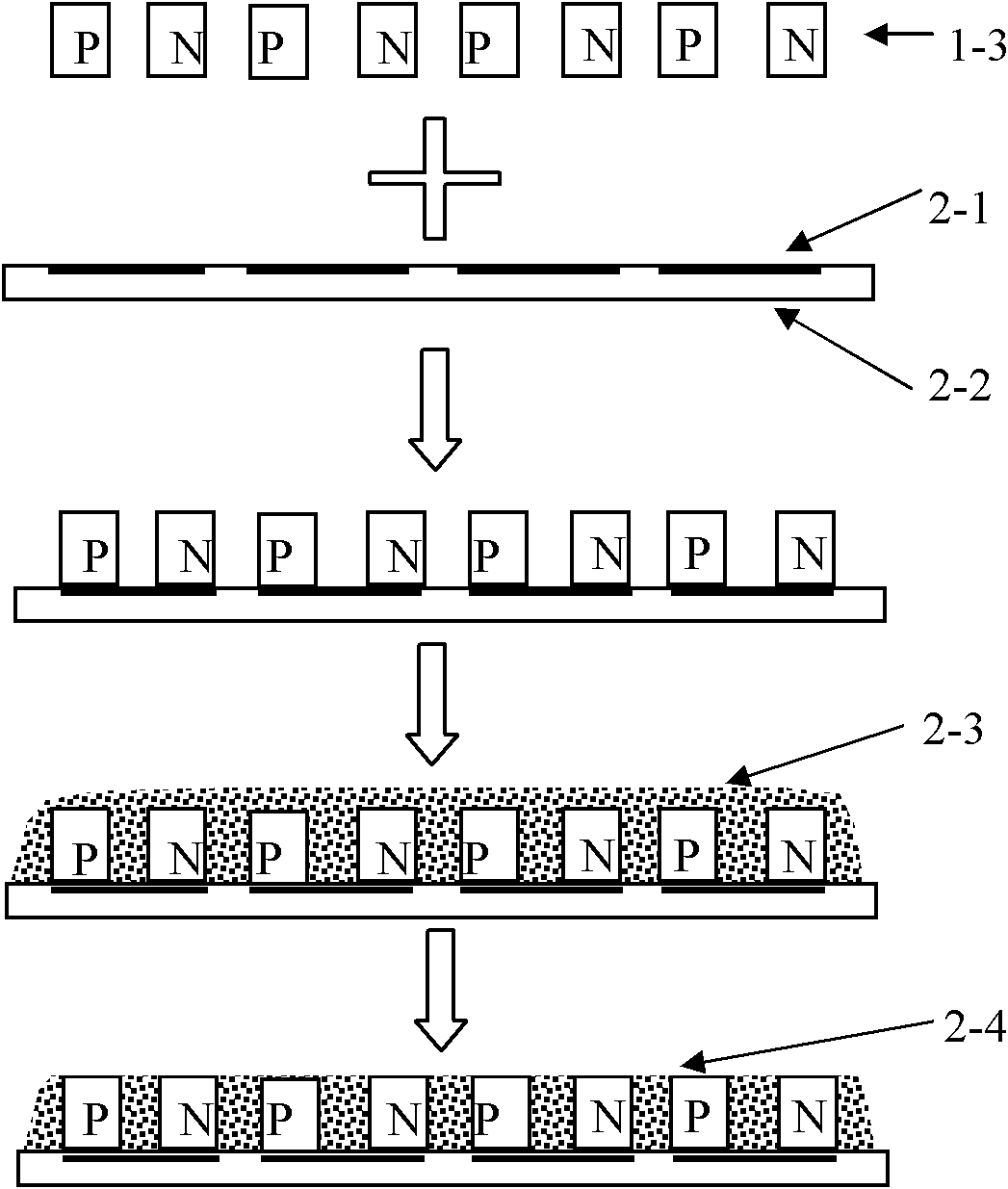

Embodiment 1

[0046] Example 1, using low-temperature solder with a melting point temperature of only 138 degrees to weld the semiconductor block, using Thomas potting glue with a heat-resistant temperature of 360 degrees for potting, and curing at a temperature of 80 degrees for 48 hours after potting, the resulting When the manufactured thermoelectric device is used for thermoelectric power generation, the hot-end substrate can withstand a high temperature of 260 degrees for a long time without being damaged.

Embodiment 2

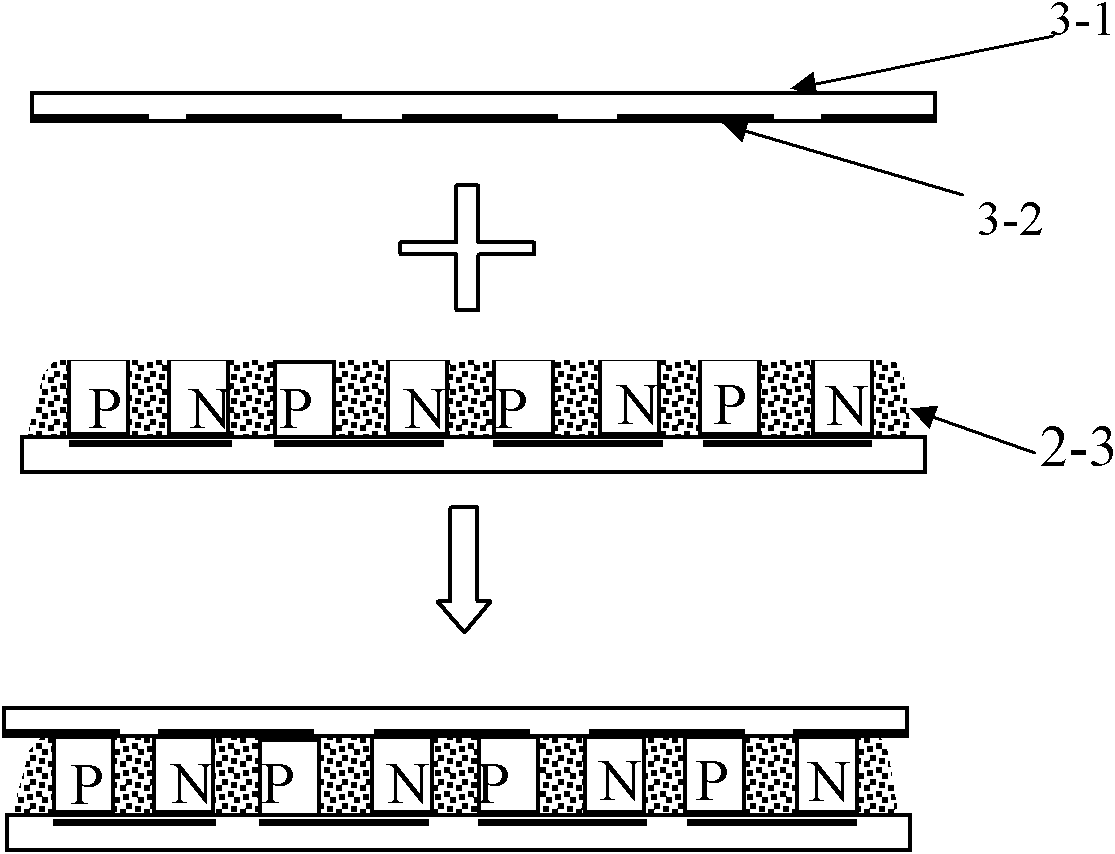

[0047] Example 2, using tin-silver solder with a melting point of 221 degrees to weld the semiconductor block, using copper oxide-phosphate inorganic glue with a heat-resistant temperature of 800 degrees for potting and sealing, and curing at 150 degrees for 48 hours after potting, When the manufactured thermoelectric device is used for thermoelectric power generation, the hot end substrate can withstand a high temperature of 360 degrees for a long time without being damaged. The instantaneous heat-resistant temperature of the hot end surface of the device reaches 450 degrees.

[0048] Such as Figure 4 As shown, in order to reduce the heat loss caused by the heat conduction of the sealing glue and the temperature difference between the hot and cold surfaces becomes smaller, when filling the heat-resistant thermosetting insulating glue, the filling amount of the glue can be reduced, and only half of the height of the thermoelectric semiconductor material block can be filled. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com