Nutritive soybean milk and preparing method thereof

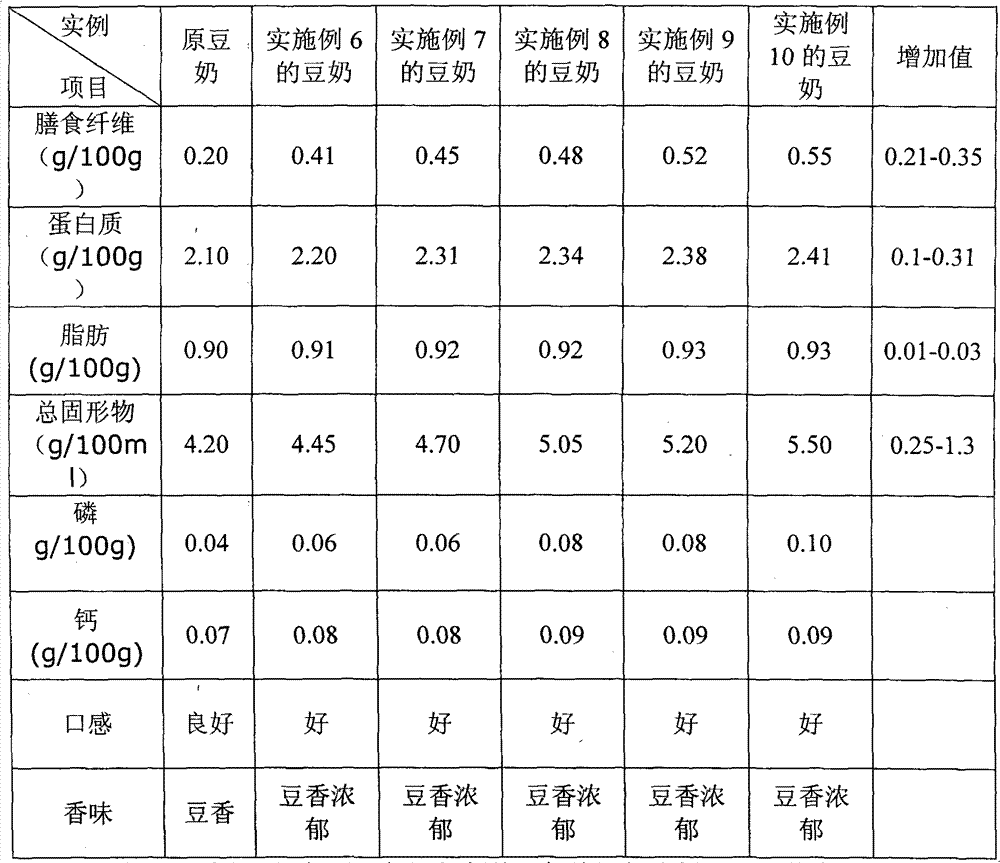

A soymilk and nutrition technology, which is applied to the field of nutritious soymilk and its production, can solve the problems of being unsuitable for direct human consumption, poor taste, and heavy fishy smell of fresh bean dregs, and achieve the effects of rich nutrition, comfortable taste and good bean flavor.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052]Press the fresh bean dregs with a filter press until no water drips down; take 60KG of processed bean dregs, 10KG of wheat bran; 0.5KG of ammonium sulfate, 0.5KG of magnesium sulfate, 1.5KG of ammonium bicarbonate and 1.5KG of glucose, and mix well; Part adjustment, the moisture content of the evenly mixed mixture of the second step is adjusted to water content 55-65% (percentage by weight); Packing, with the plastic bag of one end sealing, qualified mixture is filled plastic bag, with Press it by hand, and then seal the other end of the plastic bag; put the plastic bag containing the mixture into an autoclave, and sterilize it at 121 degrees Celsius for 1 hour; put the sterilized plastic Bag is moved into aseptic inoculation room, is cooled to room temperature; In aseptic inoculation room, mixed bacterial classification is inserted in the plastic bag; Described mixed bacterial classification is that aspergillus niger, saccharomyces cerevisiae and candida utilis are by we...

Embodiment 2

[0054] Press the fresh bean dregs with a filter press until there is no water dripping down; take 65KG of processed bean dregs, 15KG of wheat bran; 1KG of ammonium sulfate, 1KG of magnesium sulfate, 2KG of ammonium bicarbonate and 2KG of glucose, and mix evenly; The moisture content of the evenly mixed mixture of the second step is adjusted to water content 55-65% (percentage by weight); Packing, with the plastic bag of one end sealing, qualified mixture is filled plastic bag, compacts with hand, Then seal the other end of the plastic bag; put the plastic bag containing the mixture into an autoclave, and sterilize it for 1 hour at 121 degrees Celsius; move the sterilized plastic bag into a sterile Inoculation room, cooled to room temperature; in the aseptic inoculation room, the mixed strains were inserted into plastic bags; the mixed strains were prepared with Aspergillus niger, Saccharomyces cerevisiae and Candida utilis in a weight ratio of 1:3:2 The resulting mixed strain;...

Embodiment 3

[0056] Press the fresh bean dregs with a filter press until there is no water dripping; take 70KG of the treated bean dregs, 20KG of wheat bran; 1.5KG of ammonium sulfate, 1.5KG of magnesium sulfate, 2.5KG of ammonium bicarbonate and 2.5KG of glucose, mix well; Part adjustment, the moisture content of the evenly mixed mixture of the second step is adjusted to water content 55-65% (percentage by weight); Packing, with the plastic bag of one end sealing, qualified mixture is filled plastic bag, with Press it by hand, and then seal the other end of the plastic bag; put the plastic bag containing the mixture into an autoclave, and sterilize it at 121 degrees Celsius for 1 hour; put the sterilized plastic Bag is moved into aseptic inoculation room, is cooled to room temperature; In aseptic inoculation room, mixed bacterial classification is inserted in the plastic bag; Described mixed bacterial classification is that aspergillus niger, saccharomyces cerevisiae and candida utilis are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com