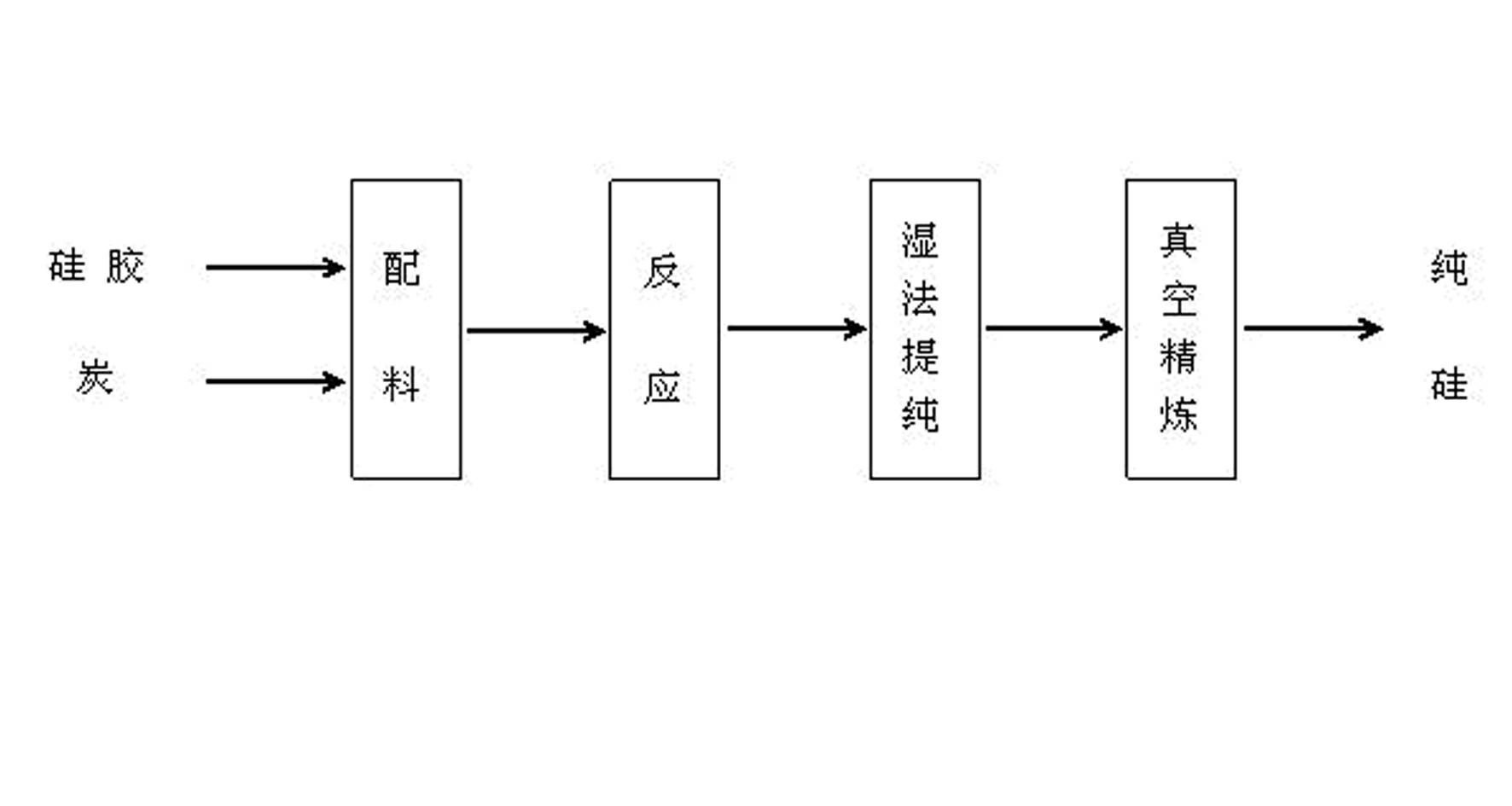

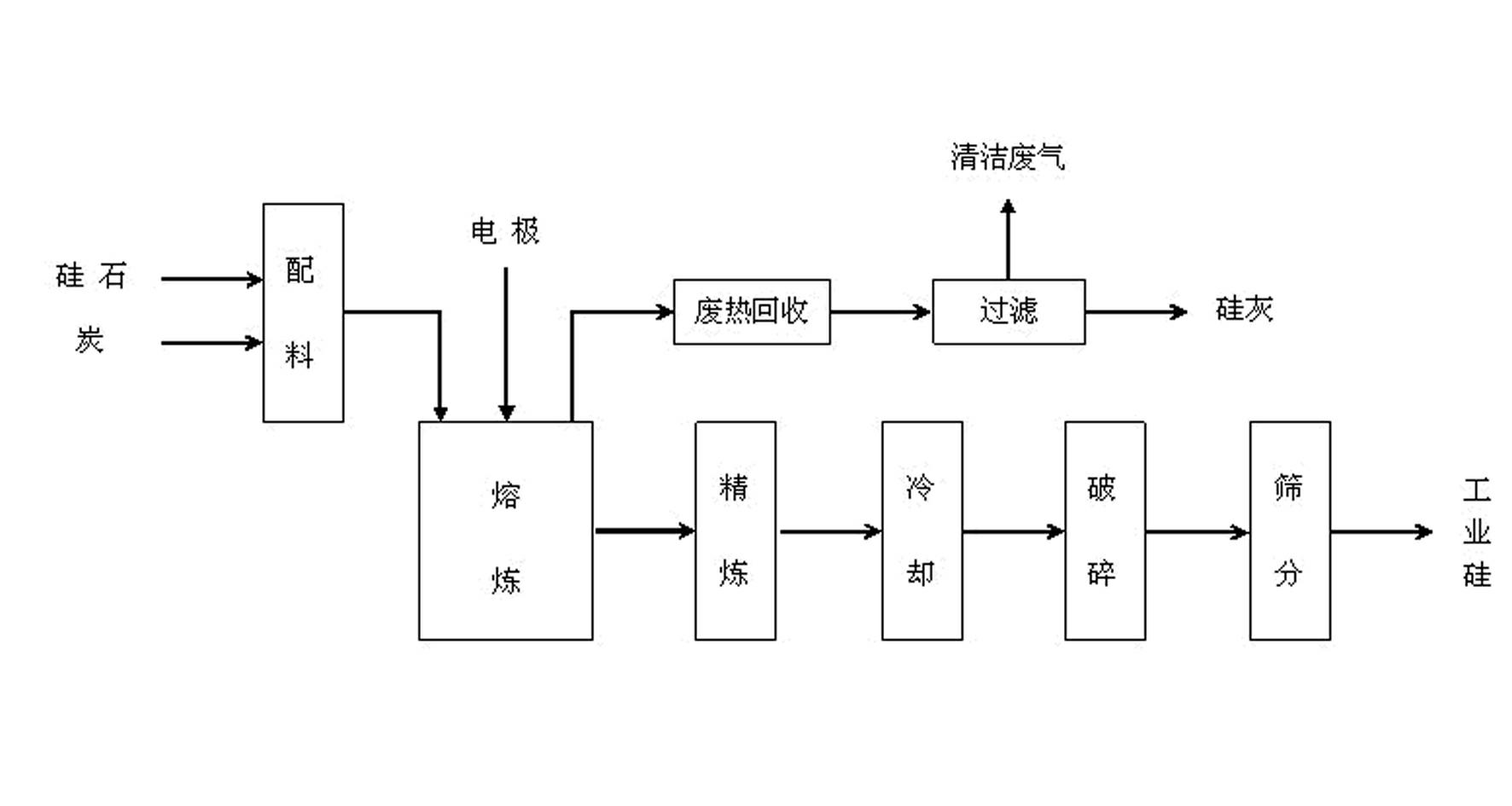

Method for producing pure silicon by using by-product silica gel in phosphate fertilizer industry

A silica gel and by-product technology, applied in chemical instruments and methods, silicon compounds, inorganic chemistry, etc., can solve the problems of increasing the burden of refining and purification, unrealized industrial production, and insignificant economic benefits, and achieve good social and economic benefits. , Conducive to protection and effective utilization, and the effect of environmental pollution control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

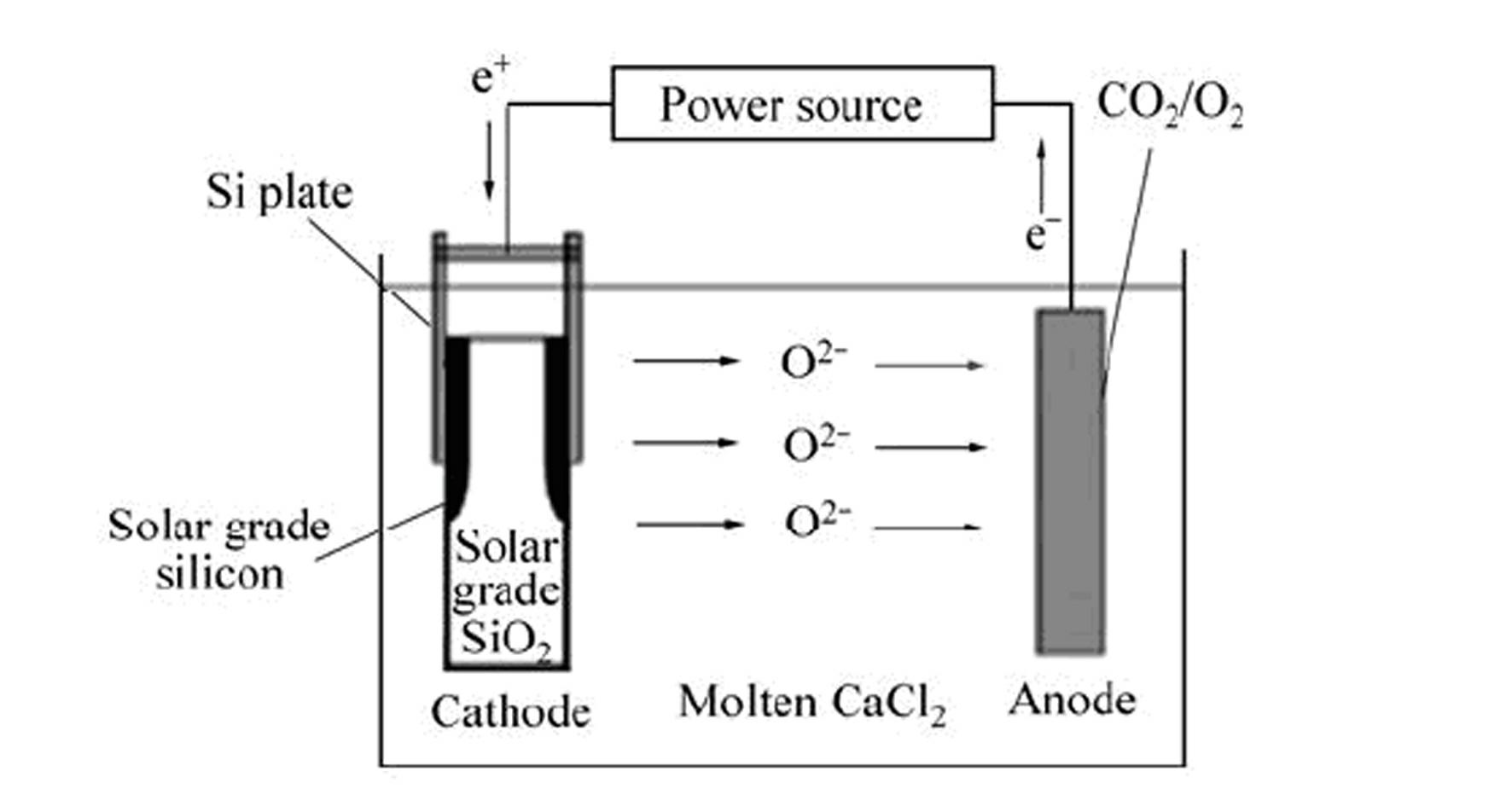

Method used

Image

Examples

Embodiment 1

[0047] After the raw materials are pretreated, according to the material ratio (C-Si ratio) as , material ratio (charcoal-petroleum coke ratio) is Perform batching; send the mixture into a high-temperature carbon tube furnace, and the preheating condition is to vacuumize to 5.0×10 -3 mbar (1mbar=100Pa), the temperature rises to 600°C, and the heating rate is 50°C·min -1 , keep warm for 20min; the protective atmosphere condition is to evacuate to 5.0×10 -2 Below mbar, argon is used as the protective gas, the protective gas pressure is 0.02MPa, and the protective gas flow rate is 7.5CFH (1CFH=472 cm 3 min -1 ), the pressure is 25mbar, the temperature rises to 1825°C, and the heating rate is 50°C·min -1 , keep warm for 25min; cool to room temperature, the product can be obtained.

Embodiment 2

[0049] After the raw materials are pretreated, according to the material ratio (C-Si ratio) as , material ratio (charcoal-petroleum coke ratio) is Perform batching; send the mixture into a high-temperature carbon tube furnace, and the preheating condition is to vacuumize to 5.0×10 -3 mbar (1mbar=100Pa), heating up to 600℃, the heating rate is 50℃·min -1 , keep warm for 20min; the protective atmosphere condition is to evacuate to 5.0×10 -2 Below mbar, argon is used as the protective gas, the protective gas pressure is 0.02MPa, and the protective gas flow rate is 7.5CFH (1CFH=472 cm 3 min -1 ), the pressure is 25mbar, the temperature rises to 1825°C, and the heating rate is 50°C·min -1 , keep warm for 25min; after the reaction product is cooled and crushed, when the silicon powder particle size is D=150~75μm, the wet purification stage is two stages, the leaching agent is 8.00% HCl, 5.15% HF, and the liquid-solid ratio is 5:1, the stirring rate is 140 rad min -1 Under ...

Embodiment 3

[0051] After the raw materials are pretreated, according to the material ratio (C-Si ratio) as , material ratio (charcoal-petroleum coke ratio) is Perform batching; send the mixture into a high-temperature carbon tube furnace, and the preheating condition is to vacuumize to 5.0×10 -3 mbar (1mbar=100Pa), heating up to 500~700℃, the heating rate is 25~50℃·min -1 , keep warm for 10-30 minutes; the protective atmosphere condition is to vacuumize to 5.0×10 -2 Below mbar, argon is used as the protective gas, the protective gas pressure is 0.02MPa, and the protective gas flow rate is 7.5CFH (1CFH=472 cm 3 min -1 ), the pressure is 50mbar, the temperature rises to 1775°C, and the heating rate is 50°C·min -1 , keep warm for 30min; after the reaction product is cooled and crushed, when the particle size of silicon powder is D=150~75μm, the number of wet purification stages is two, the leaching agent is 8.00% HCl, 5.15% HF, and the liquid-solid ratio is 5:1, the stirring rate is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com