Glycine and application of acid salt thereof in preparation of glyphosate

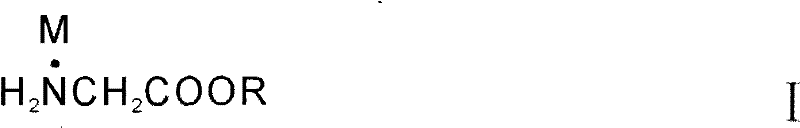

A technology of glycine hydrochloride and glycine ester is applied in the application field of glycine and its acid salt of glycine ester in the preparation of glyphosate, and can solve the problems of low cost, soil damage and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

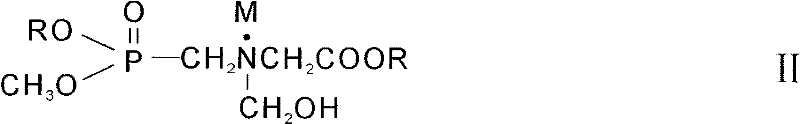

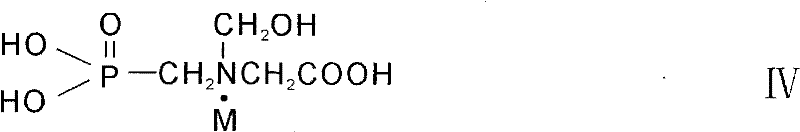

Method used

Image

Examples

Embodiment 1

[0038] Throw 100g of 98% glycine into the pressure reactor, start stirring, slowly add 318g of 30% hydrochloric acid aqueous solution at room temperature, or add 427-213g of 30-60% sulfuric acid aqueous solution, control the temperature at 20-60°C, preferably 40°C, Stir the reaction for 0.5-2 hours, preferably 1 hour, then distill the acidic aqueous solution as much as possible under vacuum or under normal pressure, and the distillate can be used for the preparation of the next batch of glycine acid salt, and the distillation substrate is glycine hydrochloride Salt, or glycine sulfate, slowly add 362-724g of anhydrous methanol to the solid glycine hydrochloride, adjust the temperature at 10-60°C, stir for 0.5-1 hour, all the solids are dissolved in methanol, and then add 98% 40-80 g of paraformaldehyde, after stirring for 0.5-1.5 hours, the solution becomes clear and transparent;

[0039] Put the above clear and transparent solution in an autoclave, and slowly heat up from 40°...

Embodiment 2

[0041]Put 100g of 98% glycine into a 2000ml pressure reactor, start stirring, slowly add 258g of 37% hydrochloric acid aqueous solution at room temperature, or add 106-214g of 30-60% sulfuric acid aqueous solution, control the temperature at 40°C, and stir for 0.5- After 1 hour, glycine hydrochloride is formed, then slowly add 80g of 98% paraformaldehyde, control the temperature at 40-60°C, stir and react for 1-4 hours, raise the temperature to 60°C, slowly add 87g of 98% phosphorous acid, Control the pressure > 0.1Mpa, control the temperature at 110-128°C, keep warm for 1-16 hours to generate hydroxymethyl glyphosate and its acid salt, add 150-850g of water or 150-1200g of 50% methanol aqueous solution, and flow back After reacting for 1-4 hours, start to deacidify for 1-2 hours, and then deacidify under a vacuum of 0.07-0.08Mpa. After steaming out the acid as much as possible, add 212g of water, stir for 10 minutes, and stand at 20-25°C for 12 hour, and then the crystallized...

Embodiment 3

[0043] Select 98% glycine hydrochloride or 100g of 98% glycine sulfate into the pressure reactor, start stirring, slowly add 400g of anhydrous methanol, stir for 0.5-1 hour to form a clear and transparent solution, and then slowly add 98% 53g of paraformaldehyde solid, stirred for 0.5-1 hour, the reaction solution became clear and transparent again, controlled the temperature at 60-128°C, slowly added 74g of 98% phosphorous acid, or slowly added 99g of 98% dimethyl phosphite, and stirred React for 1 to 16 hours to generate N-methylolglyphosate and its N-methylolglyphosate methyl ester, then slowly add 298g of 30% hydrochloric acid or 574 g of 30% to 60% sulfuric acid under normal pressure ~1148g, reflux reaction for 1~4 hours, then deacidification for 1~2 hours, then deacidification under 0.07~0.08Mpa vacuum, after steaming out the acid as much as possible, add 142g of water, stir for 10 minutes, at 20~25℃ , stand still for 12 hours, then filter the crystallized solid, and dry...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com