Film transistor, electronic equipment and manufacture method thereof

A technology of thin-film transistors and electronic equipment, which is applied in semiconductor/solid-state device manufacturing, circuits, electrical components, etc. It can solve the problems of large size, performance fluctuations such as mobility and switching ratio, and easy deterioration of active layer characteristics, so as to achieve stable performance. , the effect of improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~4

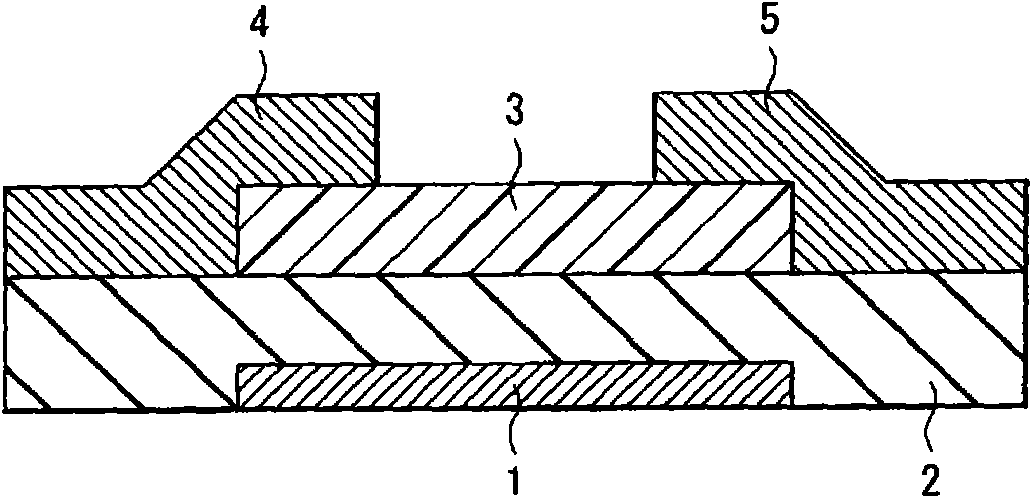

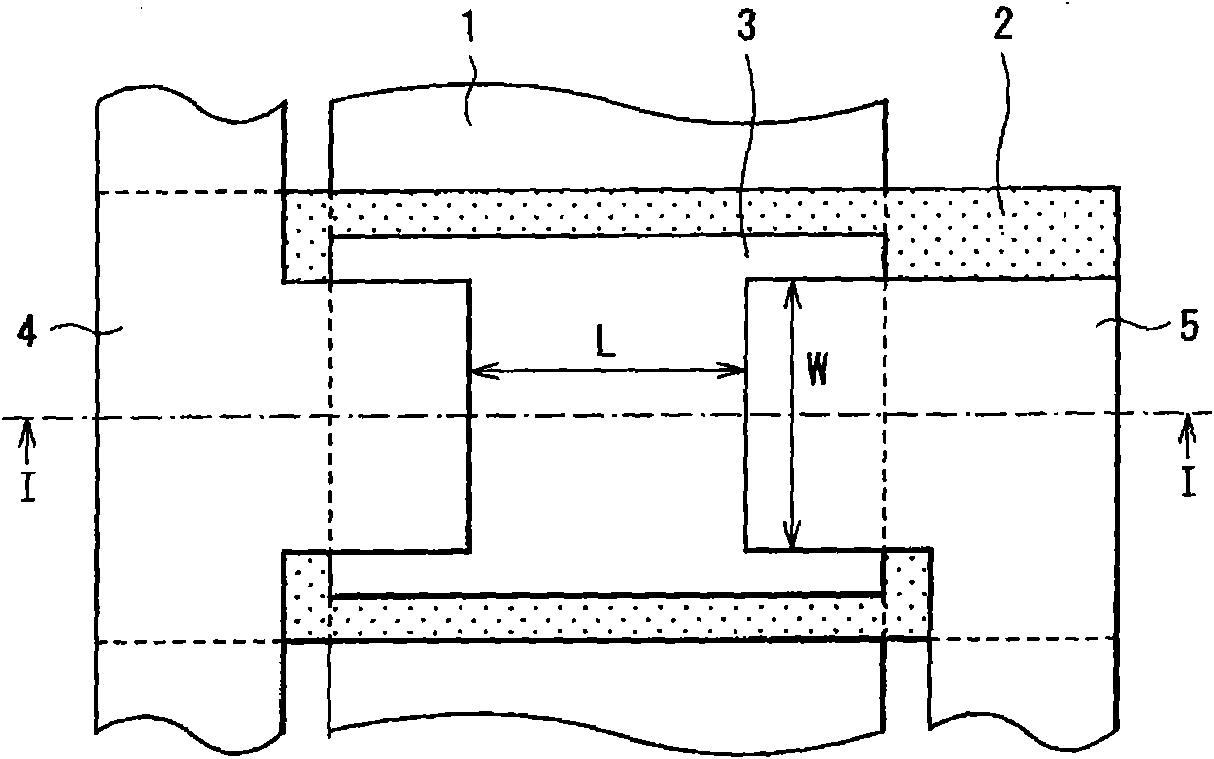

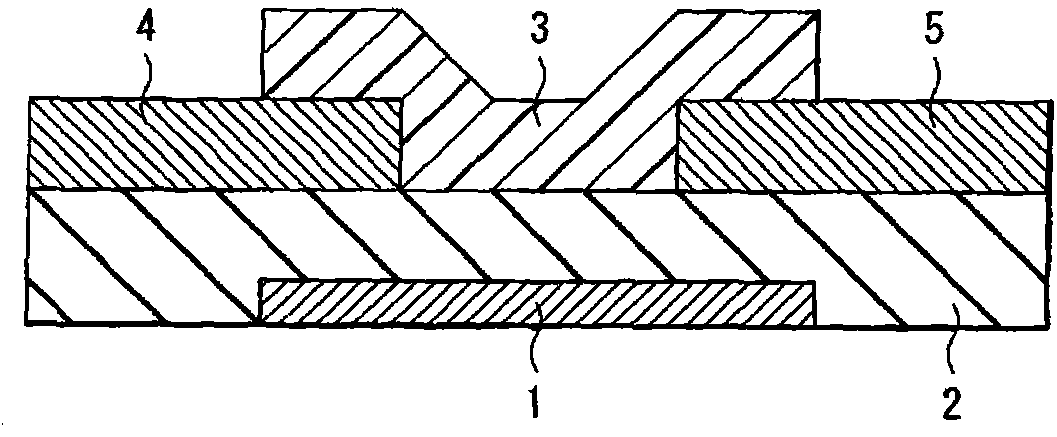

[0098] An experimental organic TFT of bottom-gate bottom-contact type was fabricated and its performance was studied. In the case of making organic TFTs, a silicon wafer doped with boron (B), phosphorus (P), antimony (Sb), or arsenic (As) is prepared first as a substrate for the gate electrode function. Then, a silicon dioxide (SiO 2 ) Constitute a gate insulating layer (thickness=150nm). Next, source and drain electrodes made of gold are formed on the gate insulating layer. In this case, make figure 2 The dimensions (L, W) shown are L=50μm and W=30mm. Next, the soluble organic semiconductor materials and soluble polymer materials (glass transition temperature Tg: °C) shown in Table 1 were dissolved in toluene to prepare a solution. In this case, the mixing ratio (weight ratio) of the soluble organic semiconductor material and the soluble polymer material is 1:1, and the total solid content is 1% by weight. As the soluble organic semiconductor material, a dioxaneanthanthren...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com