Laser device capable of freely switching laser between 1064nm wavelength and 355nm wavelength

A laser, free technology, applied in the field of lasers, which can solve the problems of low output power, limited processing speed, and inability to carry out effective processing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

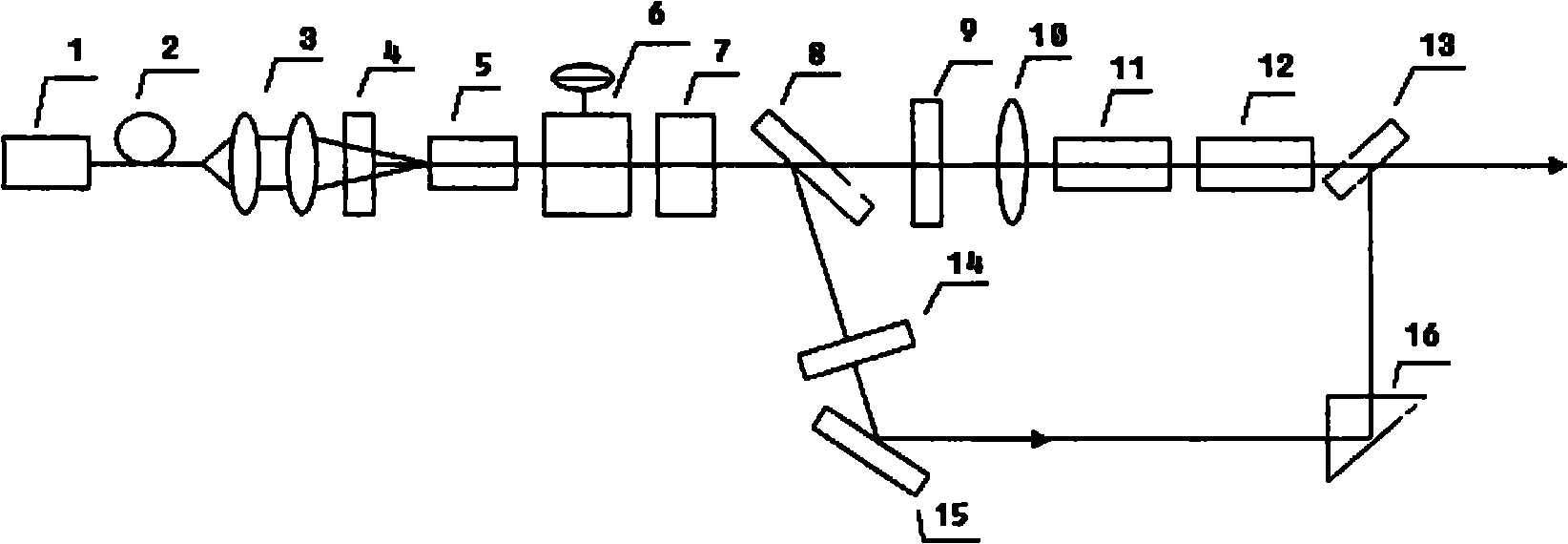

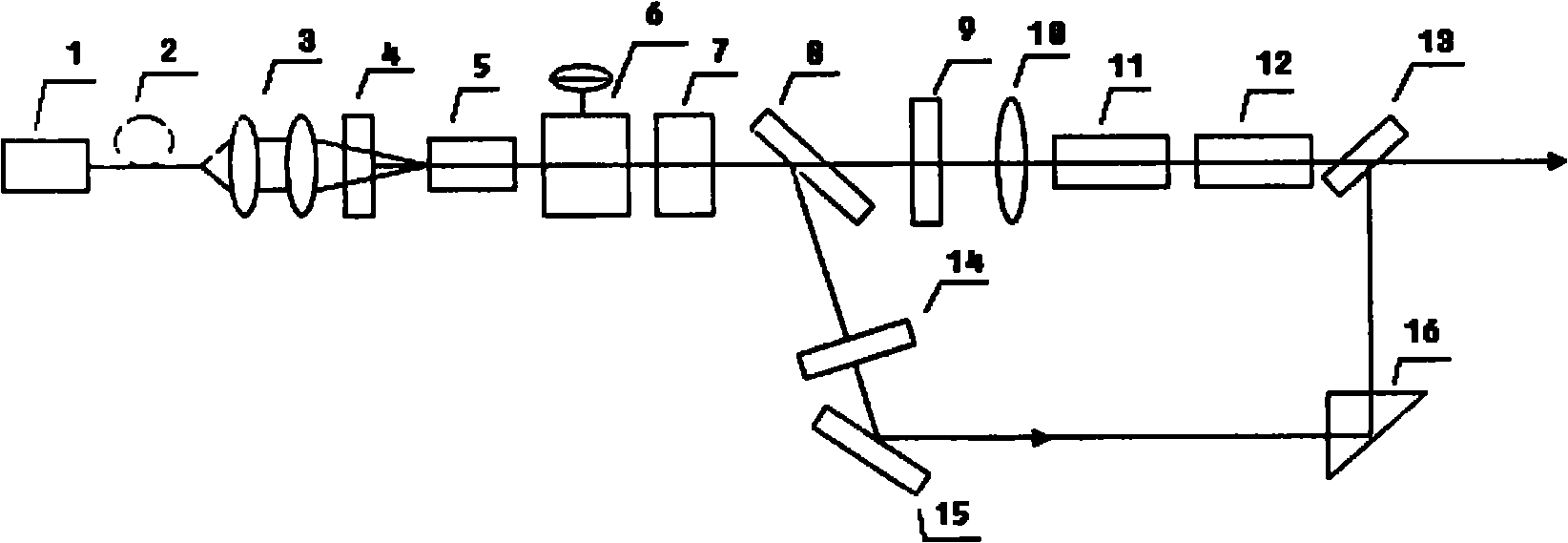

[0006] The experimental structure of the 1064nm and 355nm wavelength freely switchable output laser is shown in Figure 1, where

[0007] The output power of the pump source (1) is 30W, the central wavelength is 808.7nm, the spectral line width is ±3nm, the core diameter of the energy transmission fiber (2) is 400um, the numerical aperture is 0.22, the coupling focusing system (3) is a 1:1.5 imaging system, The total reflection mirror (4) is a flat mirror, coated with 1064nm high reflection coating and 808nm anti-reflection coating on both sides, and the laser gain medium crystal (5) is Nd:YVO 4 Crystal, doping concentration 0.2%, size 3x3x7mm 3 , acousto-optic Q switch (6) ultrasonic frequency 40.68MHz, RF power 20W, double-sided coated with 1064nm anti-reflection coating, electro-optic rotator (7) is KD * P crystal, half-wave voltage is 7600V, polarization beam splitter (8) Tp / Ts>1000:1, laser output mirror (9) is a flat mirror, coated with a film system with 1064nm transmit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com