Hand disinfectant and production method thereof

A technology of hand sanitizer and production method, applied in the direction of disinfectant, botany equipment and method, biocide, etc., can solve problems such as peroxide application defects, methemoglobinemia, teratogenicity, etc., and achieve good promotion Application prospect, good bactericidal effect, remarkable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

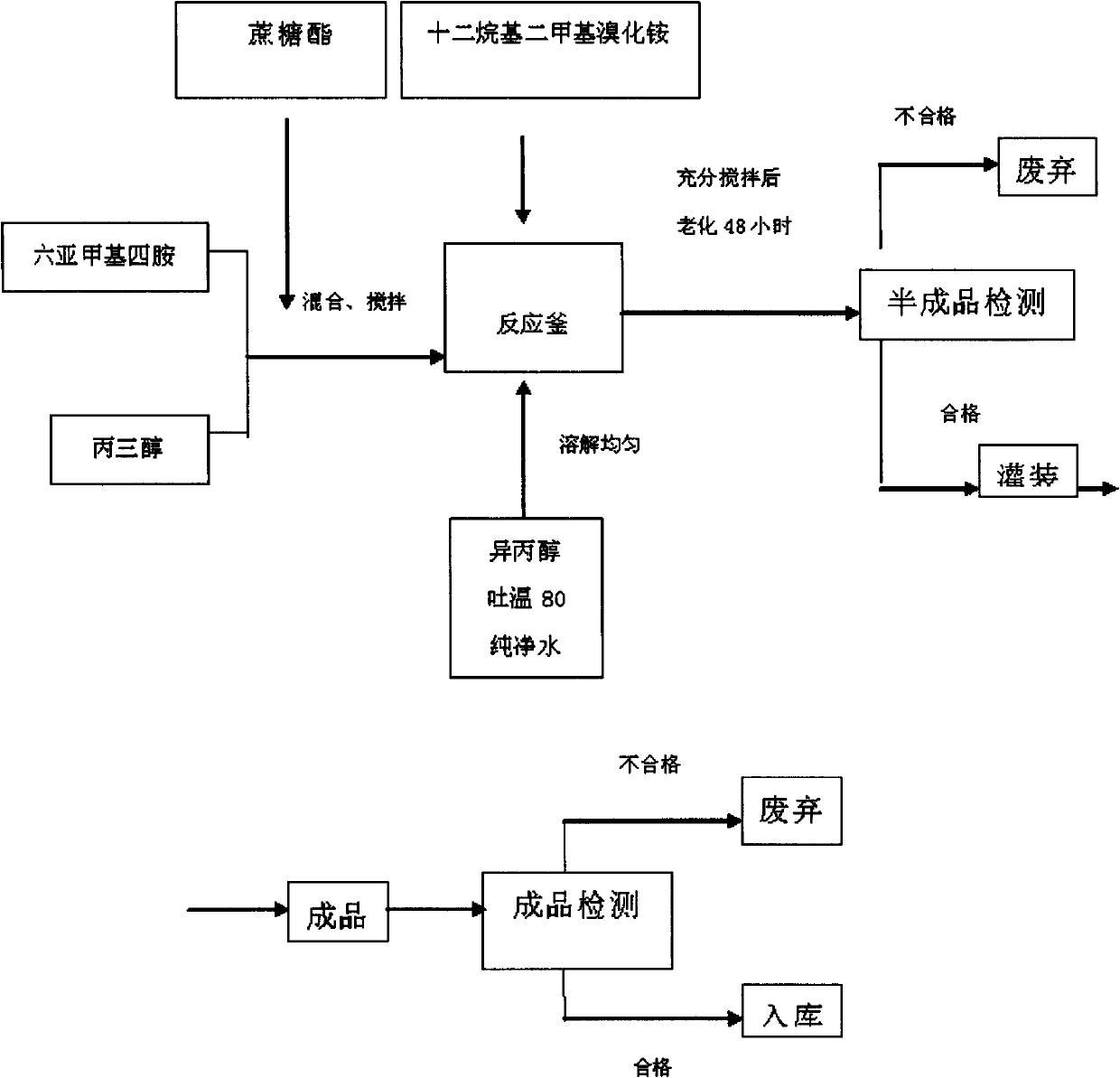

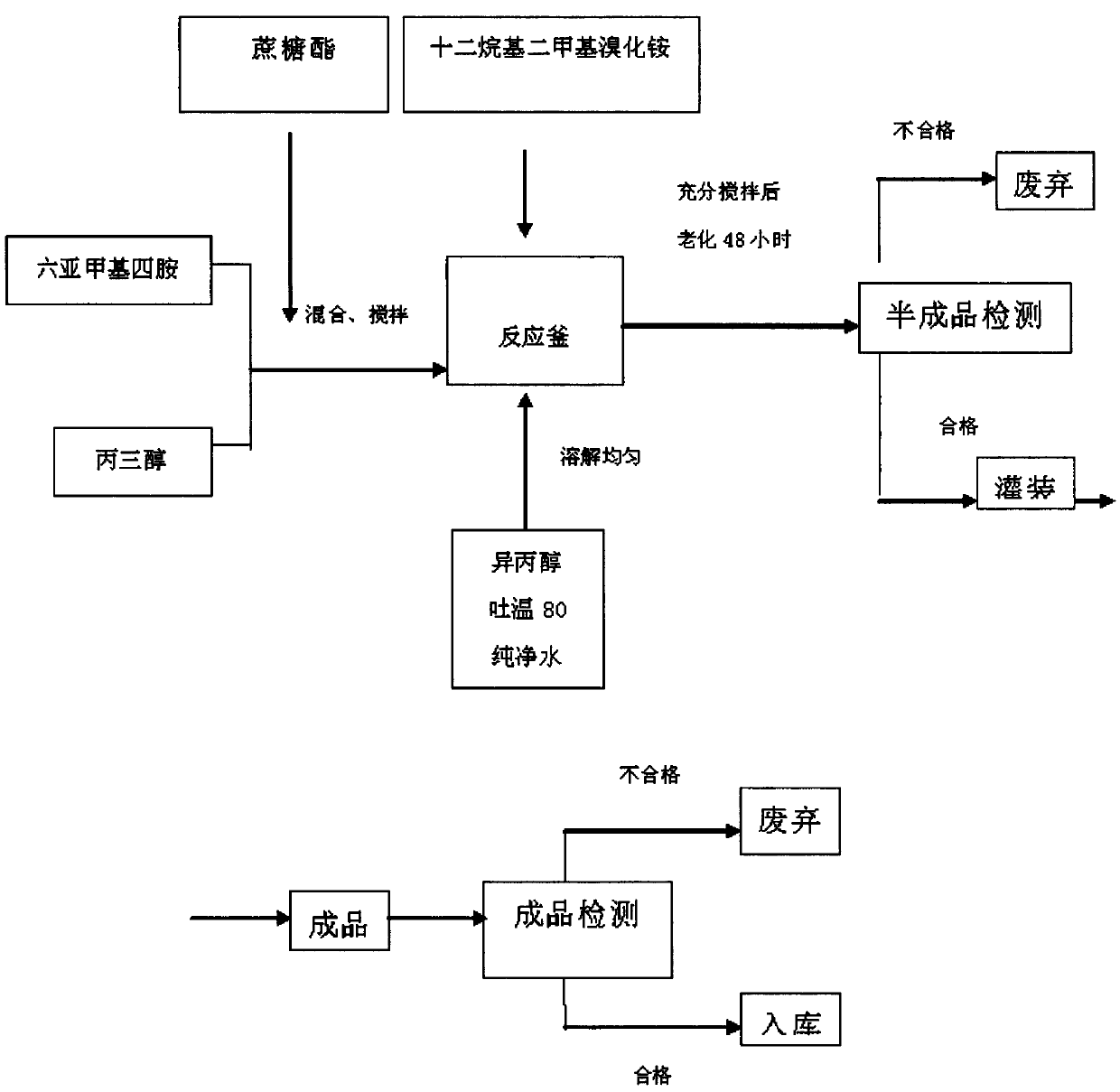

[0023] Embodiment one: a kind of production method of hand sanitizer, adopt following process steps:

[0024] (1) Add 0.05 kg of glycerol to 0.1 kg of hexamethylenetetramine, then add 0.05 kg of sucrose ester, mix and stir for 2 hours at 30°C and a pressure of 100KPa, and the speed of the mixer is 110 rpm; Add to the reaction kettle after stirring;

[0025] (2) 0.02 kilogram of lauryl dimethyl ammonium bromide is joined in the reactor; Then 0.05 kilogram of Virahol, 0.05 kilogram of Tween 80 and 99.68 kilograms of pure water are mixed and added in the reactor, at 30 Stir for 6 hours under the condition of ℃ and pressure of 100KPa, and the speed of the mixer is 510 rpm;

[0026] (3) After the material in the reaction kettle was left to age for 49 hours, after the content of the active ingredient was detected to be qualified, it was poured into a packaging barrel to obtain the finished hand sanitizer. The active ingredient content should be (in mass percent): 0.1% of hexamethy...

Embodiment 2

[0028] Embodiment two: a kind of production method of hand sanitizer adopts following processing steps:

[0029] (1) Add 0.5 kg of glycerol to 0.25 kg of hexamethylenetetramine, then add 0.5 kg of sucrose ester, mix and stir for 1.5 hours at 25°C and a pressure of 101KPa, and the speed of the mixer is 105 rpm; Add to the reaction kettle after stirring;

[0030] (2) 0.1 kilogram of lauryl dimethyl ammonium bromide is joined in the reactor; Then 0.5 kilogram of Virahol, 0.5 kilogram of Tween 80 and 97.65 kilograms of pure water are mixed and added in the reactor, at 25 Stir for 5 hours under the conditions of ℃ and pressure of 101KPa, and the speed of the mixer is 505 rpm;

[0031] (3) After the material in the reaction kettle was left to age for 48 hours, after the content of the active ingredient was detected to be qualified, pour it into a packaging barrel to obtain the finished hand sanitizer. The detected active ingredient content is (unit: mass percentage): 0.25% of hexa...

Embodiment 3

[0032] Embodiment three: a kind of production method of hand sanitizer, adopt following process steps:

[0033] (1) Add 1 kg of glycerol to 0.5 kg of hexamethylenetetramine, then add 1 kg of sucrose ester, mix and stir for 1 hour at 20°C and a pressure of 100KPa, and the speed of the mixer is 100 rpm; Add to the reaction kettle after stirring;

[0034](2) 0.2 kilogram of lauryl dimethyl ammonium bromide is joined in the reactor; Then 1 kilogram of Virahol, 1 kilogram of Tween 80 and 95.3 kilograms of pure water are mixed and then added in the reactor, at 20 Stir for 4 hours under the condition of ℃ and pressure of 100KPa, and the speed of the mixer is 500 rpm;

[0035] (3) After the material in the reaction kettle was left to age for 47 hours, after the content of the active ingredient was detected to be qualified, it was poured into a packaging barrel to obtain the finished hand sanitizer. The detected active ingredient content is (unit is mass percentage): 0.5% of hexameth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com