Method for directly leaching electrolytic zinc anode mud manganese dioxide

A manganese dioxide, electrolytic zinc technology, applied in the direction of improving process efficiency, etc., can solve the problems such as no related technology and patent documents, occupying land resources, and potential safety hazards, and achieves easy implementation and promotion, simple process, and easy operation. easy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

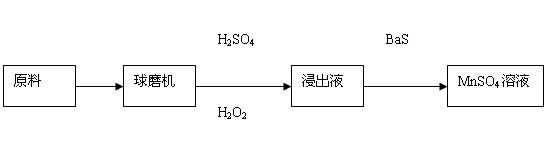

Method used

Image

Examples

Embodiment 1

[0019] When removing impurities from heavy metals in the slurry leach solution, the filtered manganese sulfate solution is controlled at a temperature of 55-60°C and a pH value of 2.0-3.0, and barium sulfide reagent is added slowly. Containing 1 / 30 of the manganese mass, a qualified manganese sulfate solution can be obtained after removing impurities from heavy metals. The content of each trace element in the qualified manganese sulfate solution is shown in Table 2. Press filtration is carried out after passing the test, and the qualified solution can be directly removed. Production of MnSO 4 ·H 2 O finished product or supply electrolytic zinc production system to supplement metal manganese. The hydrogen peroxide used is a reducing agent, which must react under acidic conditions.

[0020] Table 1 is the content of various trace elements in the leachate:

[0021] element

[0022] Table 2 is the content of trace elements after manganese sulfate solution purification...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com