Laminated magnetic conducting plate and manufacturing method thereof

A manufacturing method and technology of a magnetic conductive plate, applied in chemical instruments and methods, layered products, magnetic properties of inorganic materials, etc., can solve the problems of poor mechanical strength, low heat resistance of products, loose powder structure, etc. The effect of improving adhesion and heat resistance, excellent mechanical properties, and insulating properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

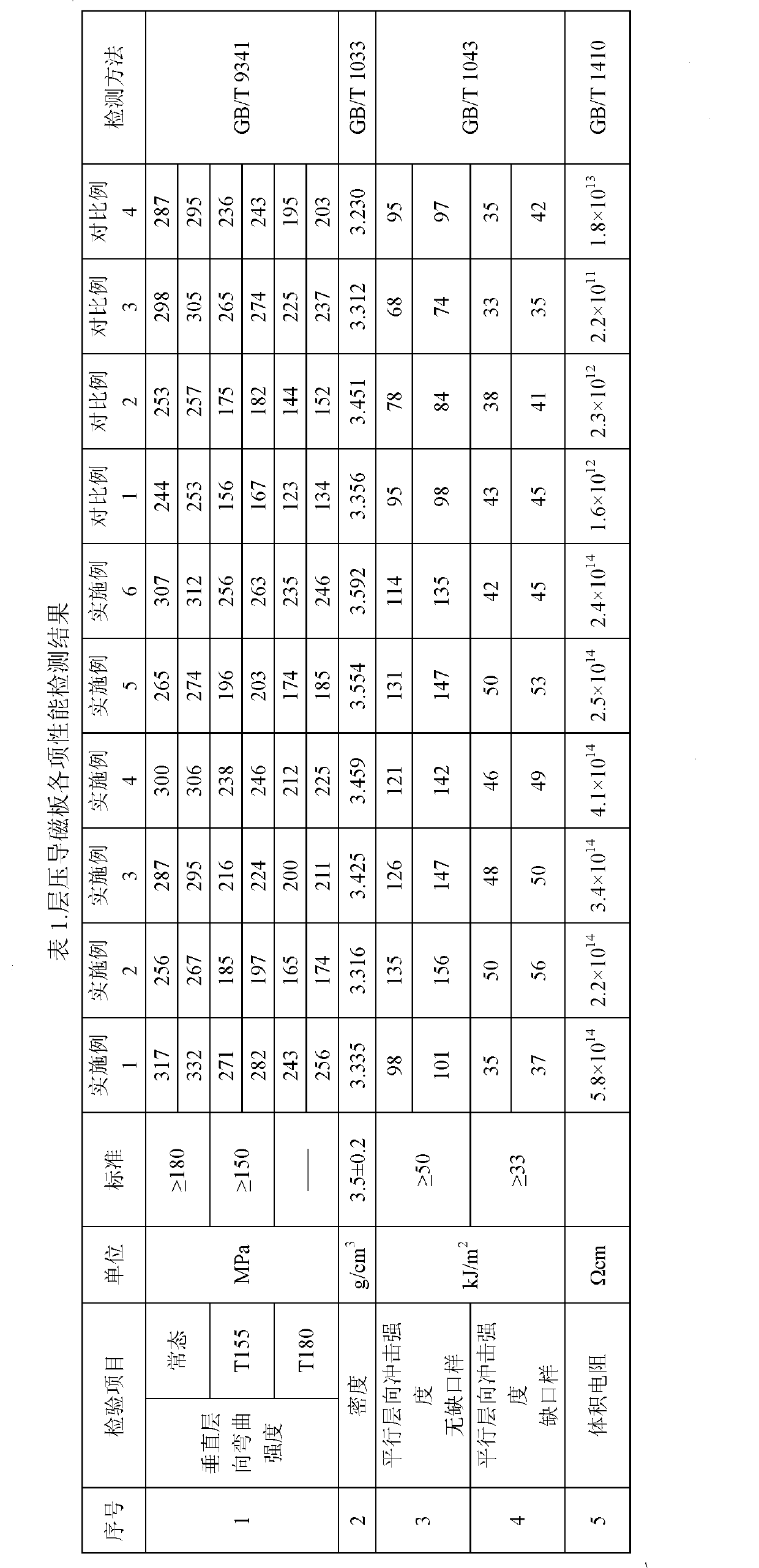

Examples

Embodiment 1

[0028] 100 parts by weight of composite resin, 30 parts by weight of diaminodiphenylsulfone, 1.0 parts by weight of boron trifluoride monoethylamine, 30 parts by weight of composite solvent, 2,6-di-tertiary butyl-4-methylphenol and sulfur 0.7 parts by weight of dioctadecyl dipropionate mixed at a mass ratio of 3 / 2, and 0.3 parts by weight of KH550 are uniformly mixed, slowly and uniformly added 370 parts by weight of 100 mesh reduced iron powder and stirred evenly with a high-speed mixer to obtain a paste , a soft magnetic resin paste with a viscosity of 20000mPa.s; the magnetic resin paste is uniformly coated on the surface of 100 parts by weight of alkali-free glass fiber cloth or glass fiber cloth for electrical use (60 grams per square meter), and the evenly coated resin paste The glass cloth passes through a vertical furnace with a furnace temperature of 120°C and a vehicle speed of 0.5 meters per minute. The resin-pasted glass cloth coming out of the furnace becomes a pre...

Embodiment 2

[0030]100 parts by weight of composite resin, 30 parts by weight of diaminodiphenylsulfone, 1.0 parts by weight of boron trifluoride monoethylamine, 30 parts by weight of composite solvent, 2,6-di-tertiary butyl-4-methylphenol and sulfur 0.7 parts by weight of dioctadecyl dipropionate mixed at a mass ratio of 3 / 2, and 0.3 parts by weight of KH550 are uniformly mixed, slowly and uniformly added 370 parts by weight of 100 mesh reduced iron powder and stirred evenly with a high-speed mixer to obtain a paste , a soft magnetic resin paste with a viscosity of 20000mPa.s; the magnetic resin paste is uniformly coated on the surface of 100 parts by weight of alkali-free glass fiber cloth or glass fiber cloth for electrical use (60 grams per square meter), and the evenly coated resin paste The glass cloth passes through a vertical furnace with a furnace temperature of 120°C and a vehicle speed of 0.5 meters per minute. The resin-pasted glass cloth coming out of the furnace becomes a prep...

Embodiment 3

[0032] 100 parts by weight of composite resin, 5 parts by weight of dicyandiamide, 0.05 parts by weight of 2-methylimidazole, 25 parts by weight of composite solvent, 2,6-two-tertiary butyl-4-methylphenol and trioctyl phosphate Mix 1.5 parts by weight of the mixture with a mass ratio of 5 / 3, and 0.5 parts by weight of KH5600. Stir evenly to obtain a paste-like magnetic resin paste with a viscosity of 100,000mPa.s; the magnetic resin paste is evenly coated on the surface of 90 parts by weight of alkali-free glass fiber cloth or glass fiber cloth for electrical use (250 grams per square meter), Evenly coated resin-pasted glass cloth passes through a horizontal furnace with a furnace temperature of 180 degrees and a vehicle speed of 5 meters per minute. The resin-pasted glass cloth coming out of the furnace becomes a prepreg, and the mass of the obtained prepreg is 2000 grams per square meter; The prepreg is cut according to the required size, laid up according to the required th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com