Smoke denitrification method and equipment utilizing same

A treatment method and flue gas technology, applied in separation methods, chemical instruments and methods, dispersed particle separation, etc., can solve problems such as difficult to apply in small and medium-scale industrial environments, complex processes, etc., to eliminate the possibility of secondary pollution , Simplify the process flow, the effect of small radius

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Ferrous sulfate (FeSO 4 ) Dissolved in water to make Fe 2+ The concentration is 3.0g / L, and Fe 2+ Aqueous solution.

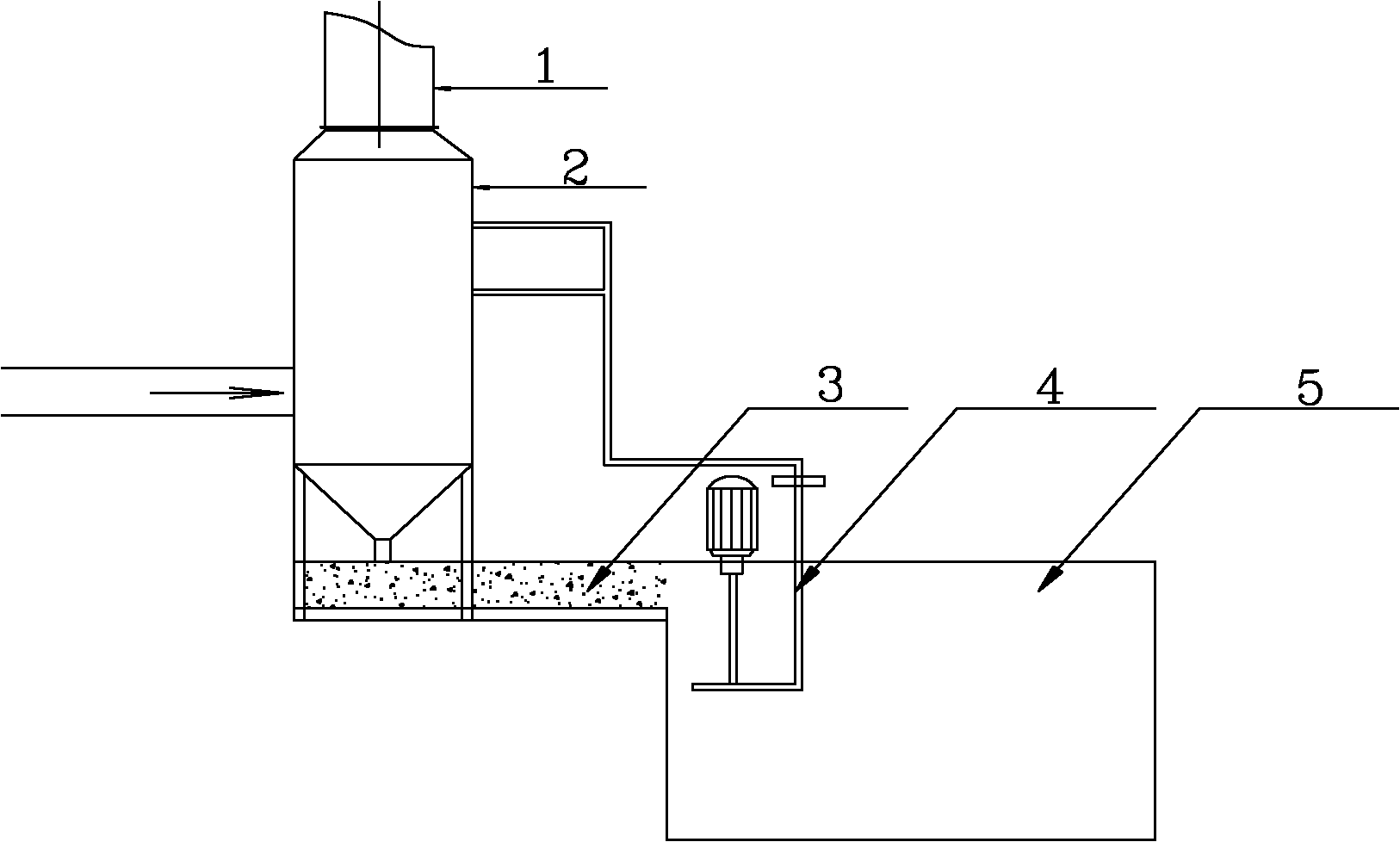

[0023] use figure 1 In the equipment shown, the above-mentioned aqueous solution is added to the liquid storage tank 5, and the circulating device 4 is used to transport it to the aerosol mixer 2, and spray it through a high-efficiency atomizing nozzle; the flue gas containing nitrogen oxides is discharged from the flue gas channel 1. Flow into the aerosol mixer 2 to fully contact the metal cations with nitrogen oxides to generate complex products. The reaction formula is (take NO as an example):

[0024] NO+FeSO 4 =Fe(NO)SO 4

[0025] The complex product decomposes under acidic conditions to generate nitrogen and metal cations, and the reaction formula is:

[0026] 2Fe(NO)SO 4 +H 2 SO 4 =Fe 2 (SO 4 ) 3 +N 2 ↑+H 2 O

[0027] Among them, the gas flow rate in the aerosol mixer is 3m / s, the reaction time of the aerosol mixer is 3.5 seconds, the airflow distribution...

Embodiment 2

[0030] Copper sulfate (CuSO 4 ) Dissolved in water to make Cu 2+ The concentration is 2.5g / L, and Cu is prepared 2+ Aqueous solution, set aside.

[0031] use figure 1 In the equipment shown, the above-mentioned aqueous solution is added to the liquid storage tank 5, and is transported to the aerosol mixer 2 by a circulating device, and sprayed through a high-efficiency atomizing nozzle; the flue gas containing nitrogen oxides flows into the flue gas channel 1 The aerosol mixer 2 makes the metal cations fully contact with nitrogen oxides to generate complex products. The reaction formula is (take NO as an example):

[0032] NO+CuSO 4 =Cu(NO)SO 4

[0033] The complex product decomposes under acidic conditions to generate nitrogen and metal cations, and the reaction formula is:

[0034] 2Cu(NO)SO 4 +H 2 SO 4 =CuSO 4 +N 2 ↑+H 2 O

[0035] The gas flow rate in the aerosol mixer is 4m / s, the reaction time of the aerosol mixer is 3 seconds, the airflow distribution of the aerosol mixer is un...

Embodiment 3

[0038] Add aluminum sulfate (Al 2 (SO 4 ) 3 ) Dissolved in water to make Al 3+ The concentration is 3.3g / L, and Al 3+ Aqueous solution, set aside.

[0039] use figure 1 In the equipment shown, the above-mentioned aqueous solution is added to the liquid storage tank 5, and is transported to the aerosol mixer 2 by a circulating device, and sprayed through a high-efficiency atomizing nozzle; the flue gas containing nitrogen oxides flows into the flue gas channel 1 The aerosol mixer 2 makes the metal cations fully contact with nitrogen oxides to generate complex products. The reaction formula is (take NO as an example):

[0040] 2NO+Al 2 (SO 4 ) 3 =Al 2 (NO) 2 (SO 4 ) 3

[0041] The complex product decomposes under acidic conditions to generate nitrogen and metal cations, and the reaction formula is:

[0042] Al 2 (NO) 2 (SO 4 ) 3 +H 2 SO 4 =Al 2 (SO 4 ) 3 +N 2 ↑+H 2 O

[0043] The gas flow rate in the aerosol mixer is 3.5m / s, the reaction time of the aerosol mixer is 3.2 seconds, the air...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com