Method for preparing volatile organic compound oxidation catalyst by ultrasound-hydrogen reduction

A technology of organic compounds and oxidation catalysts, applied in the direction of metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, chemical instruments and methods, etc., can solve the problem of high cost and achieve cost reduction and hydrogen reduction temperature low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

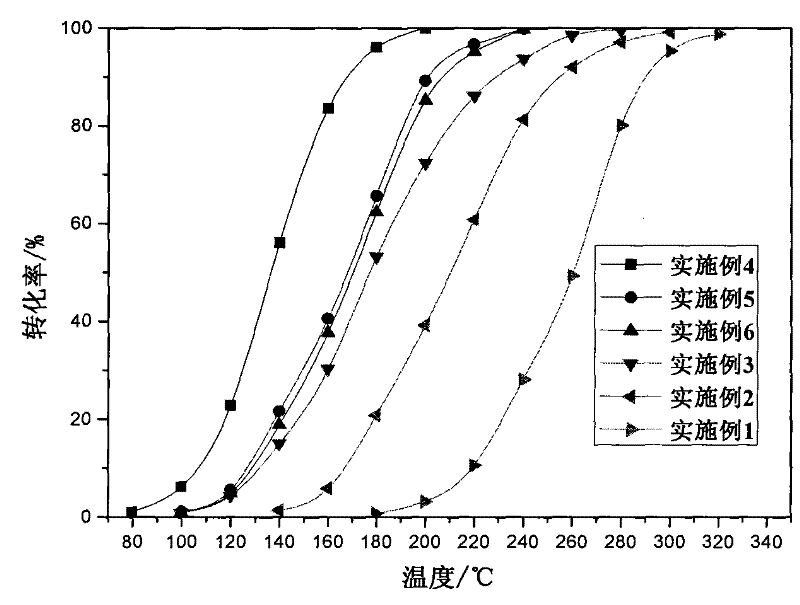

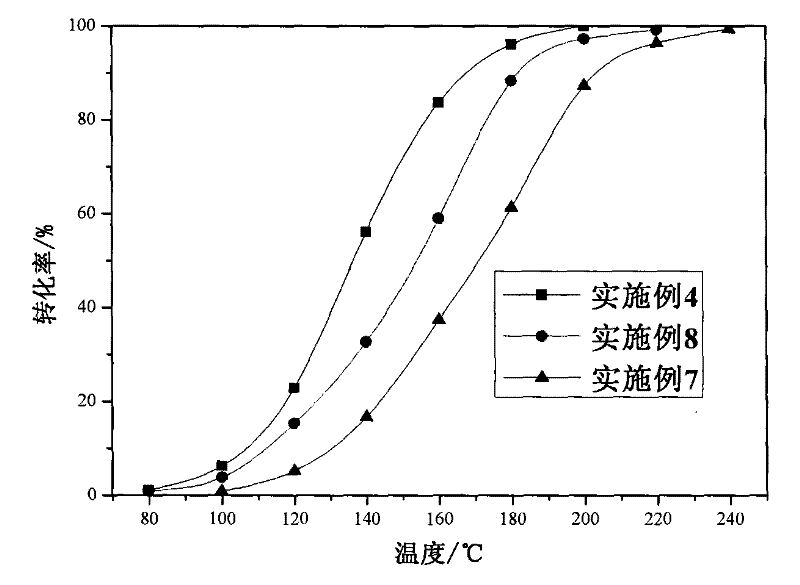

Embodiment 1

[0037] 1g TiO 2 Add 0.9mol / L of Cu(NO 3 ) 2 In the solution, impregnate in a constant temperature oscillating bed, the impregnation temperature is 30°C, and the impregnation time is 20h; then put it into an ultrasonic cleaner, and ultrasonically impregnate at 30°C for 30min, the ultrasonic radiation frequency is 45kHz, and the power is 300W; after impregnation, Put it in a vacuum dryer for drying, the drying temperature is 70°C, and the drying time is 12h; then it is placed in a muffle furnace, and it is roasted at 500°C for 5h to obtain solid particles; the obtained solid particles are placed in a fixed bed, and the volume flow 80mL / min H 2 Purging, while heating the bed to 300°C, and maintaining the temperature for 50min; then placing it in the air and roasting at 300°C for 1.5h to obtain the CuO of the present invention x / TiO 2 / HO catalyst (marked as CuO x -Us-HO-1).

Embodiment 2

[0039] 0.9mol / L Mn(CH 3 COO) 2 solution and 0.9mol / L Ce(NO 3 ) 3 The solution was mixed according to the volume ratio of 1:1, and 1g of TiO was added to it 2 , impregnated in a constant temperature oscillating bed, the impregnation temperature is 30°C, and the impregnation time is 22h; then put it into an ultrasonic cleaner, and ultrasonically impregnate at 30°C for 70min, the ultrasonic radiation frequency is 45kHz, and the power is 450W; Dry in a vacuum desiccator at a drying temperature of 120°C and a drying time of 15h; then place in a muffle furnace and roast at 700°C for 7h to obtain solid particles; place the obtained solid particles in a fixed bed at a volume flow rate of 80mL / minH 2 Purging, while heating the bed to 350°C, and maintaining the temperature for 20min; then placing it in the air and roasting at 400°C for 3h to obtain the Mn 1 Ce 1 o x / TiO 2 / HO catalyst (marked as Mn 1 Ce 1 o x -Us-HO-1).

Embodiment 3

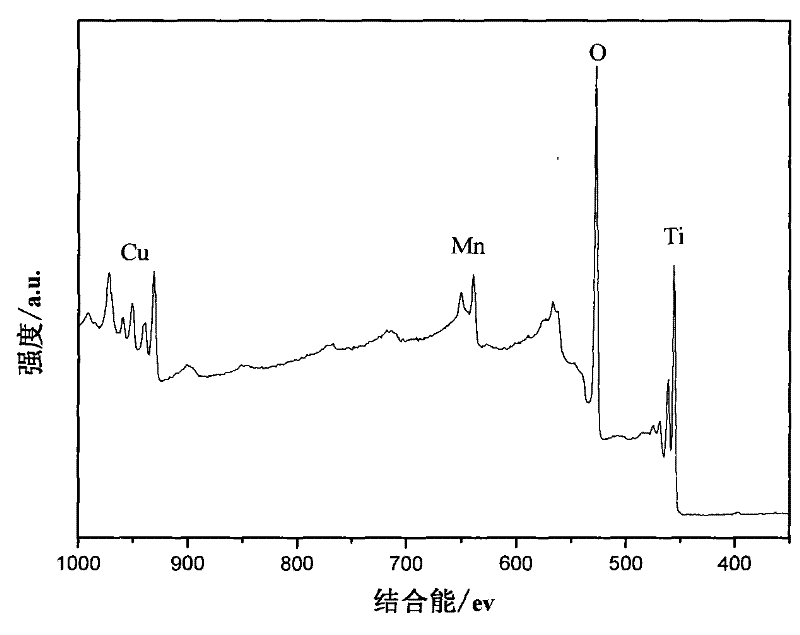

[0041] 0.9mol / L Cu(NO 3 ) 2 solution and 0.9mol / LMn(CH 3 COO) 2 The solution was mixed according to the volume ratio of 1:1, and 1g of TiO was added to it 2 , impregnated in a constant temperature oscillating bed, the impregnation temperature is 30°C, and the impregnation time is 24h; then put it into an ultrasonic cleaner, and ultrasonically impregnate at 30°C for 30min, the ultrasonic radiation frequency is 45kHz, and the power is 300W; Dry in a vacuum desiccator at a drying temperature of 80°C and a drying time of 15h; then place in a muffle furnace and roast at 550°C for 6h to obtain solid particles; place the obtained solid particles in a fixed bed at a volume flow rate of 80mL / minH 2 Purging, while heating the bed to 350°C, and maintaining the temperature for 30min; then placing it in the air and roasting at 300°C for 1.5h to obtain the Cu 1 mn 1 o x / TiO 2 / HO catalyst (marked as Cu 1 mn 1 o x -Us-HO-1).

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com