Method and device for preparing ultrathin plasma polymerization sulfonic proton exchange membrane

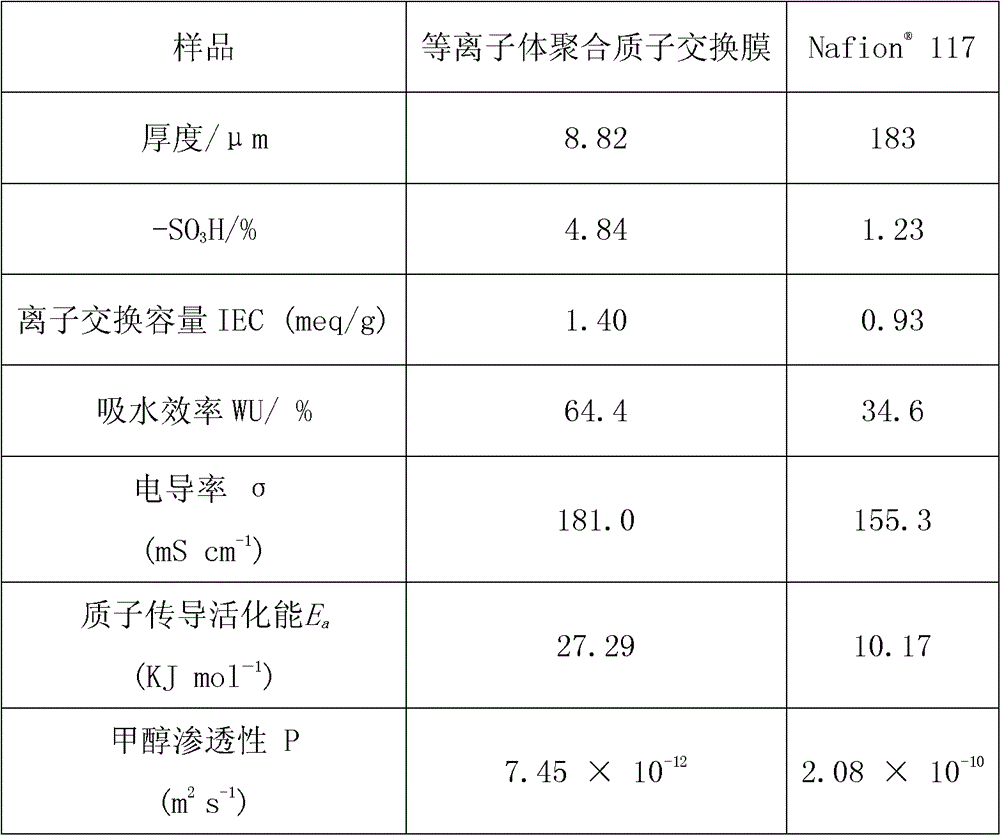

A proton exchange membrane and plasma technology, which is applied to fuel cell components, fuel cells, electrical components, etc., can solve problems such as high temperature and water content requirements, dependence on imports, short circuit of membrane electrodes, etc., to improve performance and reduce Conduction path, effect of simplifying battery structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

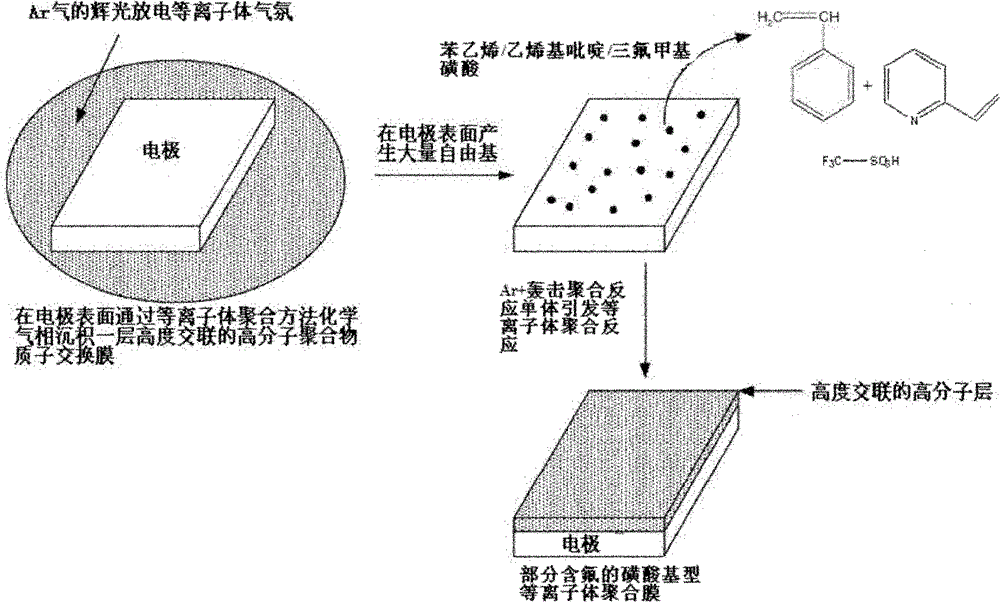

[0024] The preparation of ultra-thin plasma polymerized sulfonic acid based proton exchange membrane, the specific steps are as follows:

[0025] 1) Electrode Surface Plasma Modification Use the electrode as the plasma polymerized proton exchange membrane to deposit the substrate, put it into the vacuum chamber substrate table, and evacuate to the background pressure of 10 -3 Below Pa, pass Ar gas until the pressure of the vacuum chamber reaches about 20Pa, control the negative bias voltage of the substrate at 30V, conduct radio frequency plasma discharge under the condition of radio frequency power of 100W, and perform plasma modification on the electrode surface for 5min.

[0026] 2) Plasma polymerization film formation reaction Adjust the flow of Ar gas until the pressure of the vacuum chamber reaches about 13Pa. Then feed styrene into the gas path 1 with hydrogen as the carrier gas. Pass trifluoromethanesulfonic acid (CF 3 SO 3 H), with hydrogen as the carrier gas. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com