Synthetic resin and preparation method as well as application thereof

A technology of synthetic resin and polyester resin, which is applied in building components, building insulation materials, construction, etc., can solve the problems of secondary pollution and high processing cost, and achieve excellent results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] A kind of synthetic resin composition, by weight percentage, it is made up of 35% component A and 65% component B; Described component A is prepared from the following raw materials by weight: 20 parts of high molecular weight Polyethylene, 20 parts of polypropylene, 15 parts of saturated polyester resin, 8 parts of nylon, 10 parts of phthalic anhydride and 4 parts of pentaerythritol; said component B is prepared through degradation of the following raw materials by weight: pine tar oil 20 parts, naphthenic oil 8 parts, coumarone resin 10 parts, 420 resin 5 parts and rubber powder 57 parts.

[0048] The rubber powder is made from a mixture of 40% waste rubber from the inner and outer tires of waste automobile wheels and the rest of the natural rubber by pulverizing according to a conventional method, and the fineness is 10 meshes.

[0049] Described resin combination is prepared according to the following method:

[0050] 1. Prepare component A:

[0051] 1) Grinding t...

Embodiment 2

[0058] A kind of synthetic resin composition, by weight percent, it is made up of 35% component A and 65% component B; Described component A is polymerized by the monomer of following weight part: 20 parts of high molecular weight polyethylene, 20 parts of polypropylene, 15 parts of saturated polyester resin, 8 parts of nylon, 10 parts of phthalic anhydride and 4 parts of pentaerythritol; the component B is prepared by degradation of the following raw materials in parts by weight: pine 20 parts of tar, 8 parts of naphthenic oil, 10 parts of coumarone resin, 5 parts of 420 resin and 57 parts of rubber powder.

[0059] The rubber powder is pulverized by a conventional method from a mixture of 45% waste rubber from the inner and outer tires of automobile waste wheels and the rest of the natural rubber, and the fineness is 10 mesh.

[0060] Described resin combination is prepared according to the following method:

[0061] 1. Prepare component A:

[0062] 1) Grinding the high mo...

Embodiment 3

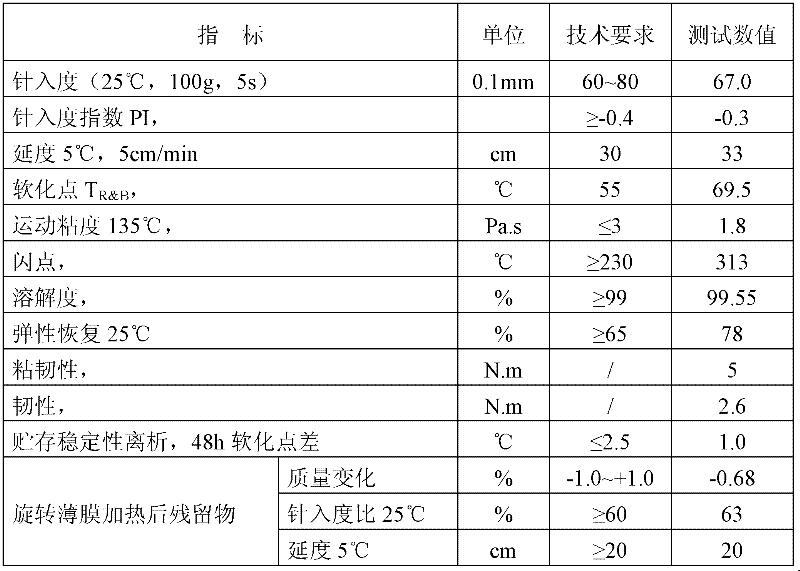

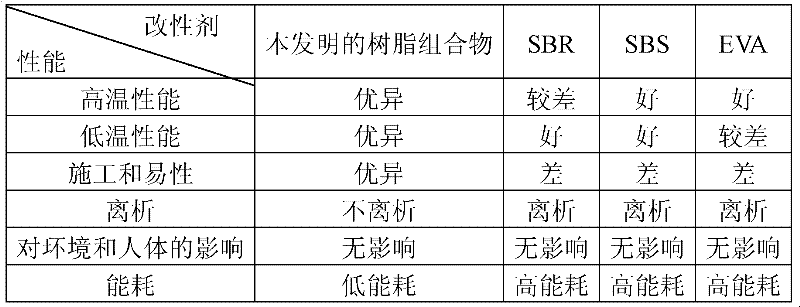

[0072] The application of resin composition of the present invention as asphalt modifier:

[0073] 1. Modification equipment: a 30-50 ton blending tank equipped with a medium-speed agitator.

[0074] Modification method: the resin composition prepared in Example 1 of the present invention and 70# matrix asphalt are put into the blending tank in proportion, wherein the resin composition I prepared in Example 1 accounts for 8% of the total weight. Start stirring to prepare. The blending temperature is 100-120°C and the blending time is 20 minutes to obtain modified asphalt.

[0075] The performance indicators of the modified asphalt are as follows:

[0076] Table 4. Asphalt technical indicators modified by the resin composition of the present invention

[0077]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fineness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com