Method for preparing high-temperature superconductive coated conductor SrZrO3 buffer film

A coating conductor and high-temperature superconducting technology, which is applied in the field of preparation of high-temperature superconducting buffer layer films, can solve problems such as affecting the superconducting properties of ReBCO, and achieve the effects of reducing production cost, easy operation control, and simple production process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

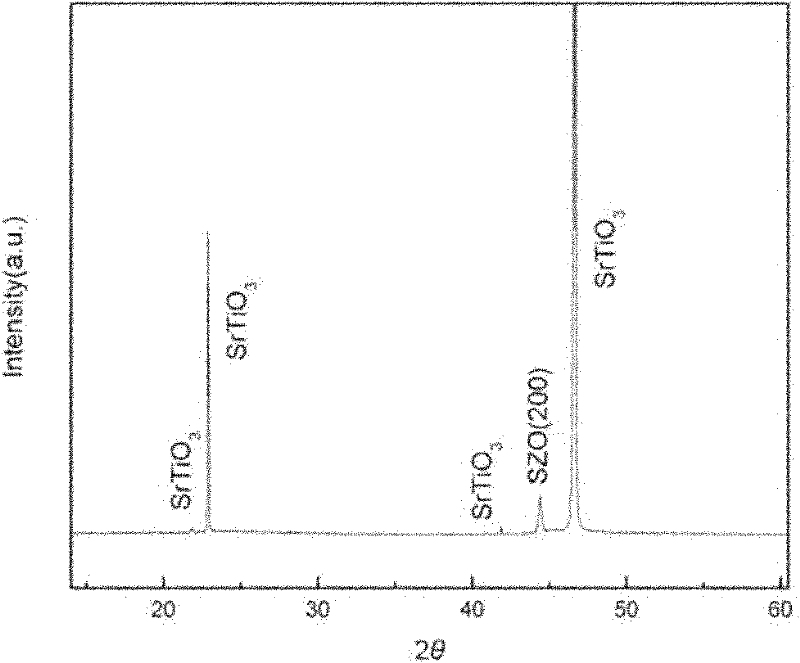

Embodiment 1

[0027] The preparation method of this example consists of the following steps in turn:

[0028] a, anhydrous solution preparation: strontium acetate and zirconium acetylacetonate are equal to the ratio of 1: 1 by the ion number ratio of strontium: zirconium, dissolve in propionic acid, form anhydrous solution;

[0029] b. Colloid preparation: Add polyvinyl butyral (PVB) to the anhydrous solution in step a to form a colloid; the amount of polyvinyl butyral (PVB) accounted for 5% of the total mass of the colloid.

[0030] c. Colloid coating and drying: coat the colloid prepared in step b on the substrate, and then dry; covered on the substrate. The temperature during drying was 150°C.

[0031] d. Thermal decomposition treatment: place the colloid-coated substrate in a sintering furnace, and feed argon into the sintering furnace to raise the furnace temperature from room temperature to 170°C at a rate of 1°C / min, and then at a rate of 0.9°C / min. The speed of min is raised to 5...

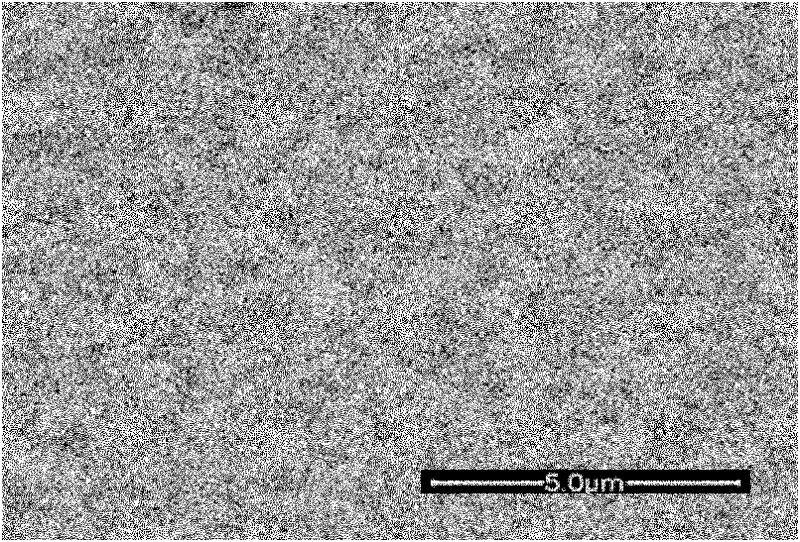

Embodiment 2

[0036] The preparation method of this example consists of the following steps in turn:

[0037] a, anhydrous solution preparation: strontium acetate and zirconium acetylacetonate are equal to the ratio of 1: 1 by the ion number ratio of strontium: zirconium, dissolve in propionic acid, form anhydrous solution;

[0038] b. Colloid preparation: Add polyvinyl butyral (PVB) to the anhydrous solution in step a to form a colloid; the amount of polyvinyl butyral (PVB) added accounts for 4% of the total mass of the colloid.

[0039] c. Colloid coating and drying: coat the colloid prepared in step b on the substrate, and then dry; covered on the substrate. The temperature during drying was 100°C.

[0040] d. Thermal decomposition treatment: place the colloid-coated substrate in a sintering furnace, and feed argon into the sintering furnace to raise the furnace temperature from room temperature to 240°C at a rate of 1°C / min, and then increase the temperature at a rate of 0.1°C / min. The...

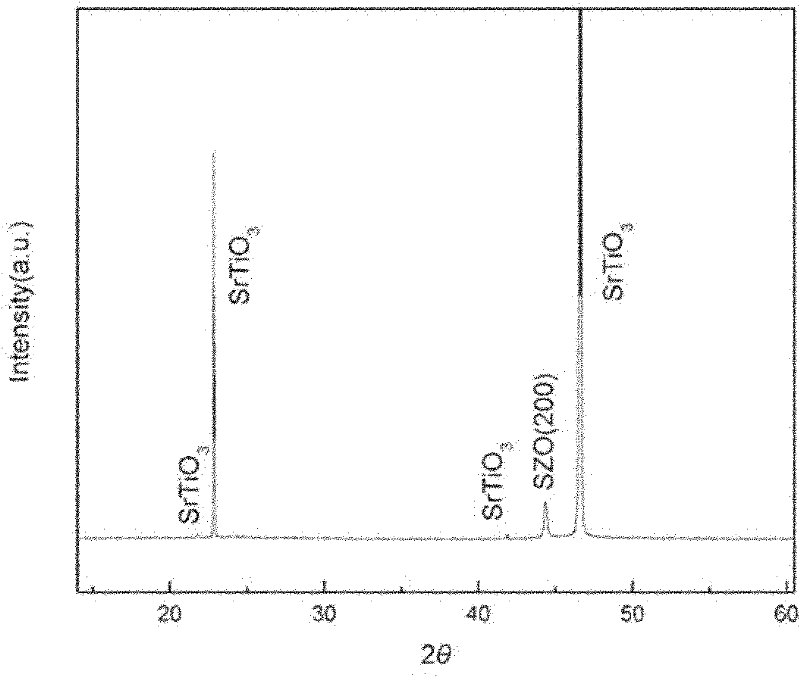

Embodiment 3

[0045] The preparation method of this example consists of the following steps in turn:

[0046] a, anhydrous solution preparation: strontium acetate and zirconium acetylacetonate are equal to the ratio of 1: 1 by the ion number ratio of strontium: zirconium, dissolve in propionic acid, form anhydrous solution;

[0047] b. Colloid preparation: Add polyvinyl butyral (PVB) to the anhydrous solution in step a to form a colloid; the amount of polyvinyl butyral (PVB) added accounts for 3% of the total mass of the colloid.

[0048] c. Colloid coating and drying: coat the colloid prepared in step b on the substrate, and then dry; covered on the substrate. The temperature during drying was 200°C.

[0049] d. Thermal decomposition treatment: place the colloid-coated substrate in a sintering furnace, and feed argon gas into the sintering furnace to raise the furnace temperature from room temperature to 190°C at 1°C / min, and then at 0.4°C / min The speed of min is raised to 530°C, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com