Double-layer hollow amorphous alloy nanometer ball as well as preparation method and application thereof

An amorphous alloy, double-layer hollow technology, applied in the preparation of nanospheres, the field of double-layer hollow amorphous alloy nanospheres, can solve the problems of alloy particle agglomeration, insufficient specific surface area, overheating, etc., and achieve simple preparation process , easy operation and long catalytic life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] 1) Add 5ml of 0.01g / ml NiCl 2 ·6H 2 O solution was added to 0.3 g of sulfonated polystyrene hollow spheres, ultrasonicated for 20 min, stirred at 25 °C for 24 h, centrifuged, and freeze-dried to obtain NiCl 2 wrapped polystyrene pellets;

[0024] 2) Add 0.1mol / L KBH at 20°C 4 The aqueous solution is added dropwise to the NiCl prepared in step 1) 2 Encased in polystyrene pellets, of which: KBH 4 with NiCl 2 The molar ratio is 5:1;

[0025] 3) Filter the black particles generated in step 2), freeze-dry, then dissolve the polystyrene pellets with DMF or THF, and wash with deionized water and absolute ethanol for 3 to 5 times respectively to obtain a double-layer hollow Ni-B Amorphous alloy nanospheres, represented by Ni-B-bilayers.

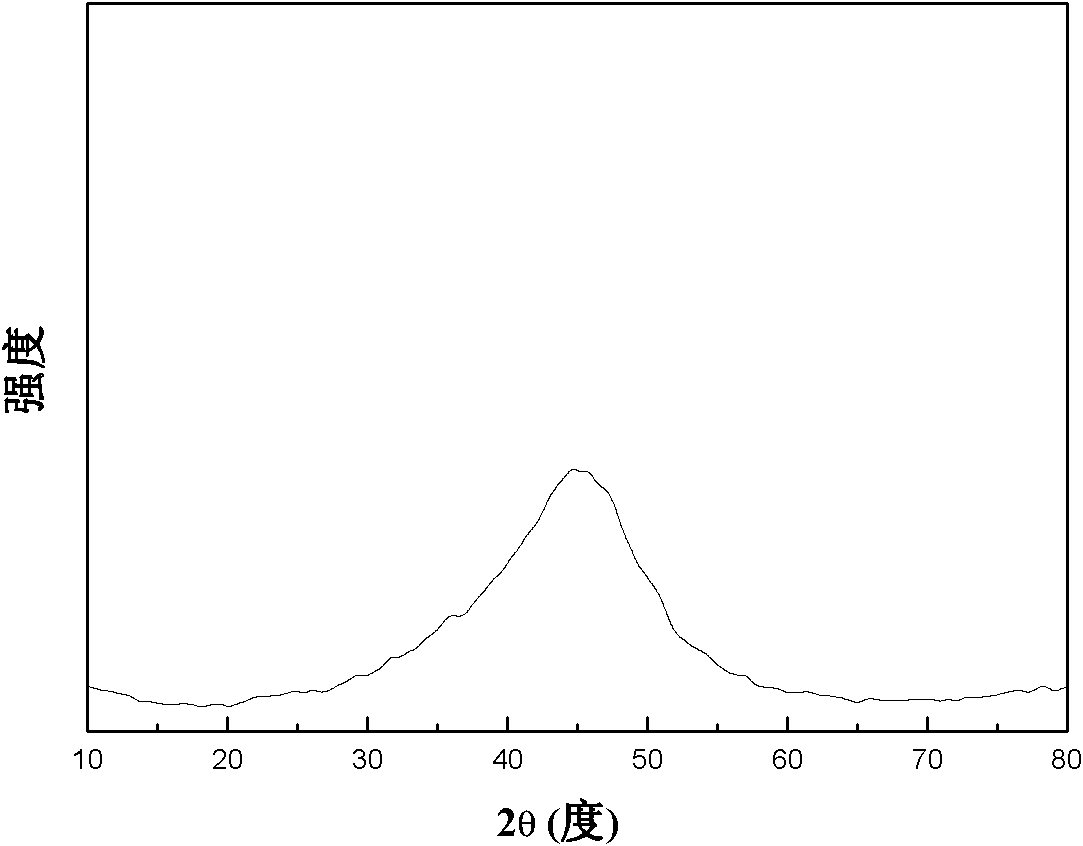

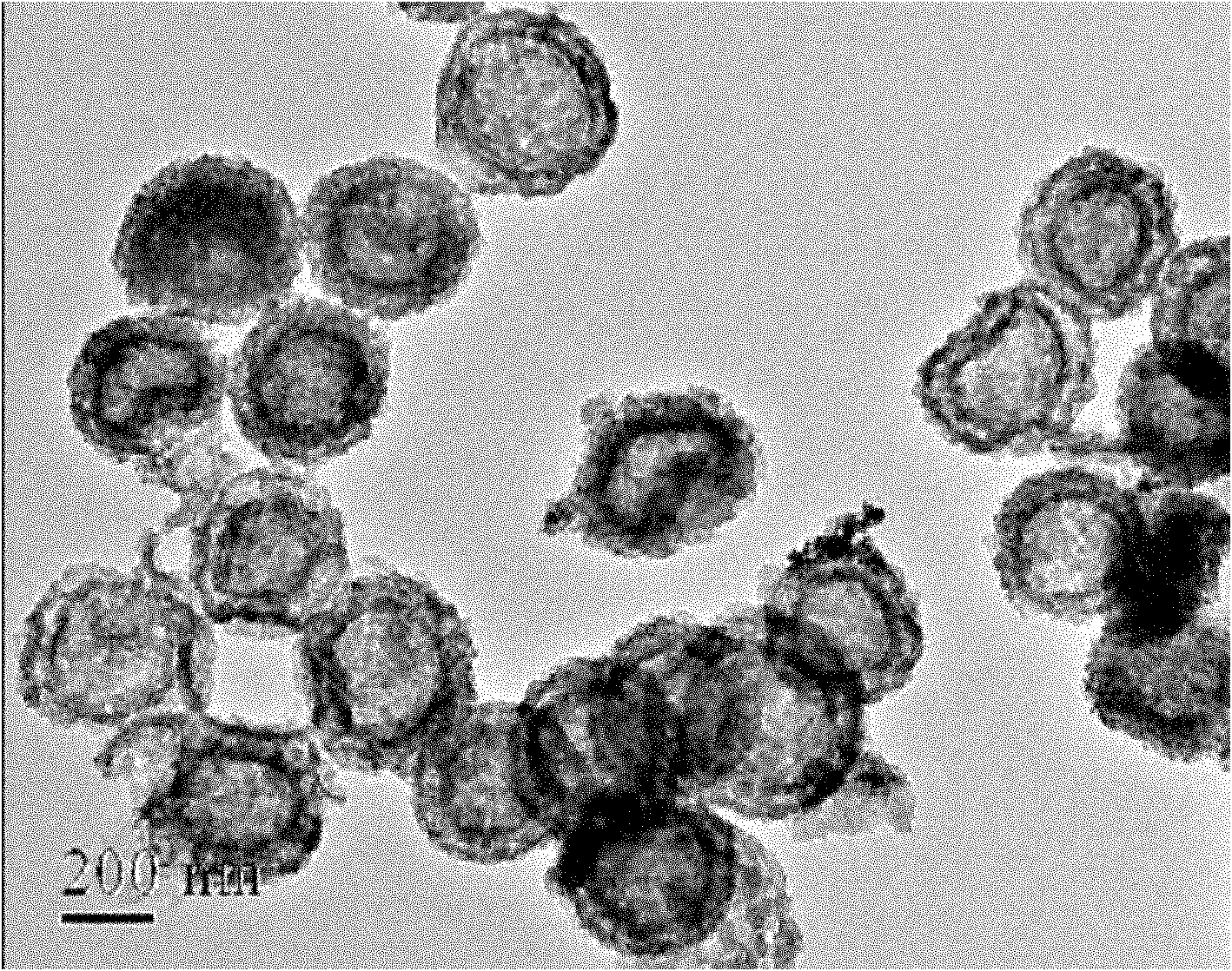

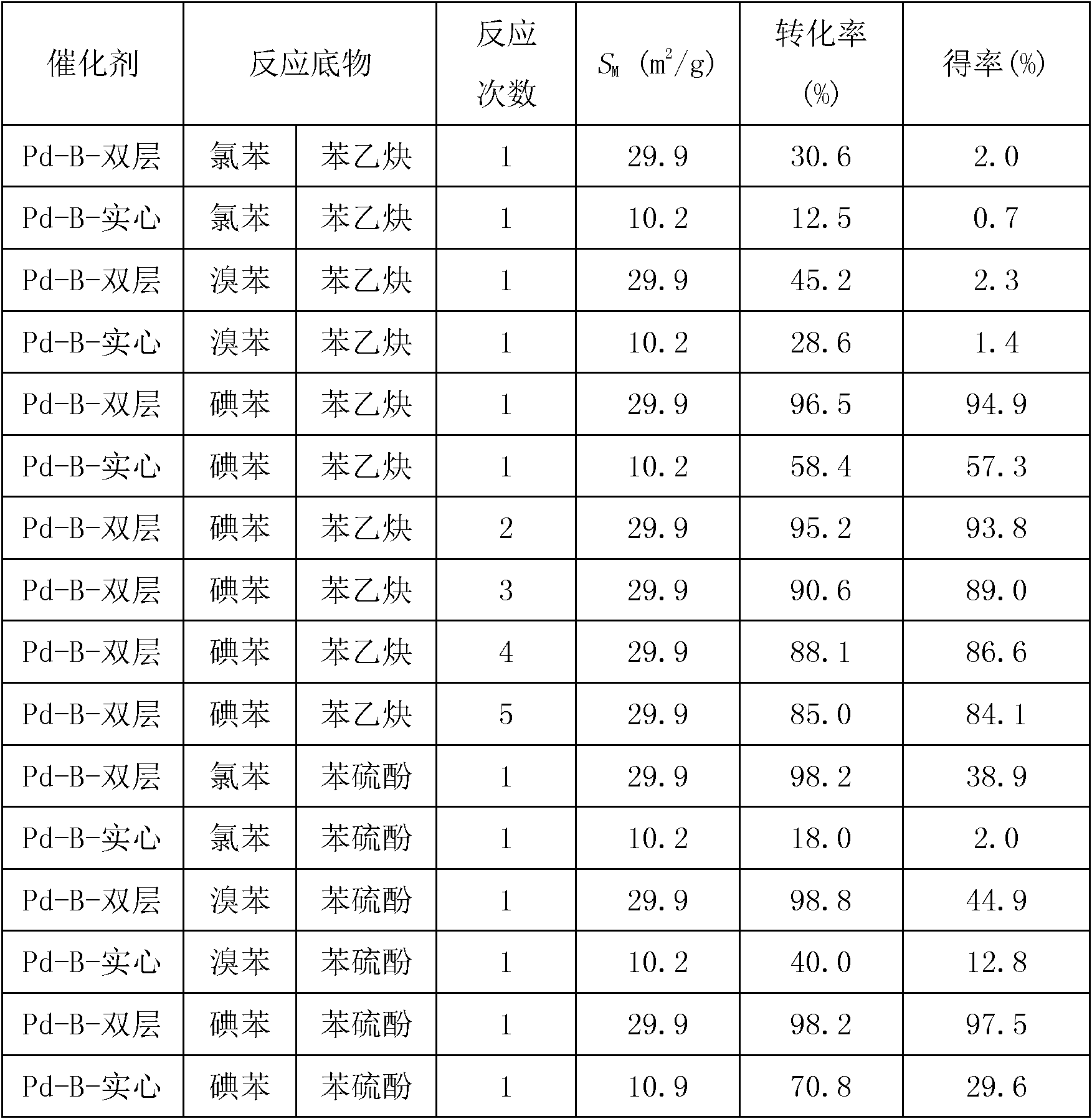

[0026] figure 1 For the XRD spectrum of the sample prepared in this embodiment, it can be determined that the prepared sample is an amorphous structure from its diffuse peak shape at about 45° position; figure 2 It is the TEM photo o...

Embodiment 2

[0029] 1) Add 3ml of 0.05g / ml NiCl 2 ·6H 2 The O solution was added to 0.3 g of sulfonated polystyrene hollow spheres, ultrasonicated for 40 min, stirred at 0 °C for 24 h, centrifuged, and freeze-dried to obtain NiCl 2 wrapped polystyrene pellets;

[0030] 2) Add 1.0mol / L KBH at 0°C 4 The aqueous solution is added dropwise to the NiCl prepared in step 1) 2 Encased in polystyrene pellets, of which: KBH 4 with NiCl 2 The molar ratio is 5:1;

[0031] 3) Filter the black particles generated in step 2), freeze-dry, dissolve polystyrene pellets with DMF or THF, and wash with deionized water and absolute ethanol for 3 to 5 times respectively to obtain the target object.

[0032] The XRD spectrogram of the sample prepared by the present embodiment can determine that the obtained sample is an amorphous alloy structure; in the TEM photo of the sample prepared by the present embodiment, it can be seen that the obtained sample is a double-layer hollow structure nanosphere, and the i...

Embodiment 3

[0035] 1) Add 5ml of 0.05g / ml NiCl 2 ·6H 2 O solution was added to 0.5 g of sulfonated polystyrene hollow spheres, ultrasonicated for 60 min, stirred at 30 °C for 24 h, centrifuged, and freeze-dried to obtain NiCl 2 wrapped polystyrene pellets;

[0036] 2) Add 1.0mol / L KBH at 30°C 4 The aqueous solution is added dropwise to the NiCl prepared in step 1) 2 Encased in polystyrene pellets, of which: KBH 4 with NiCl 2 The molar ratio is 5:1;

[0037] 3) Filter the black particles generated in step 2), freeze-dry, dissolve polystyrene pellets with DMF or THF, and wash with deionized water and absolute ethanol for 3 to 5 times respectively to obtain the target object.

[0038]The XRD spectrogram of the sample prepared by the present embodiment can determine that the obtained sample is an amorphous alloy structure; in the TEM photo of the sample prepared by the present embodiment, it can be seen that the obtained sample is a double-layer hollow structure nanosphere, and the inne...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com