Processing method and device for carrying out microwave cutting on brittle material

A technology of brittle materials and processing methods, which is applied in auxiliary devices, metal processing equipment, welding/cutting auxiliary equipment, etc. Edge and workpiece quality, the effect of ensuring energy density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

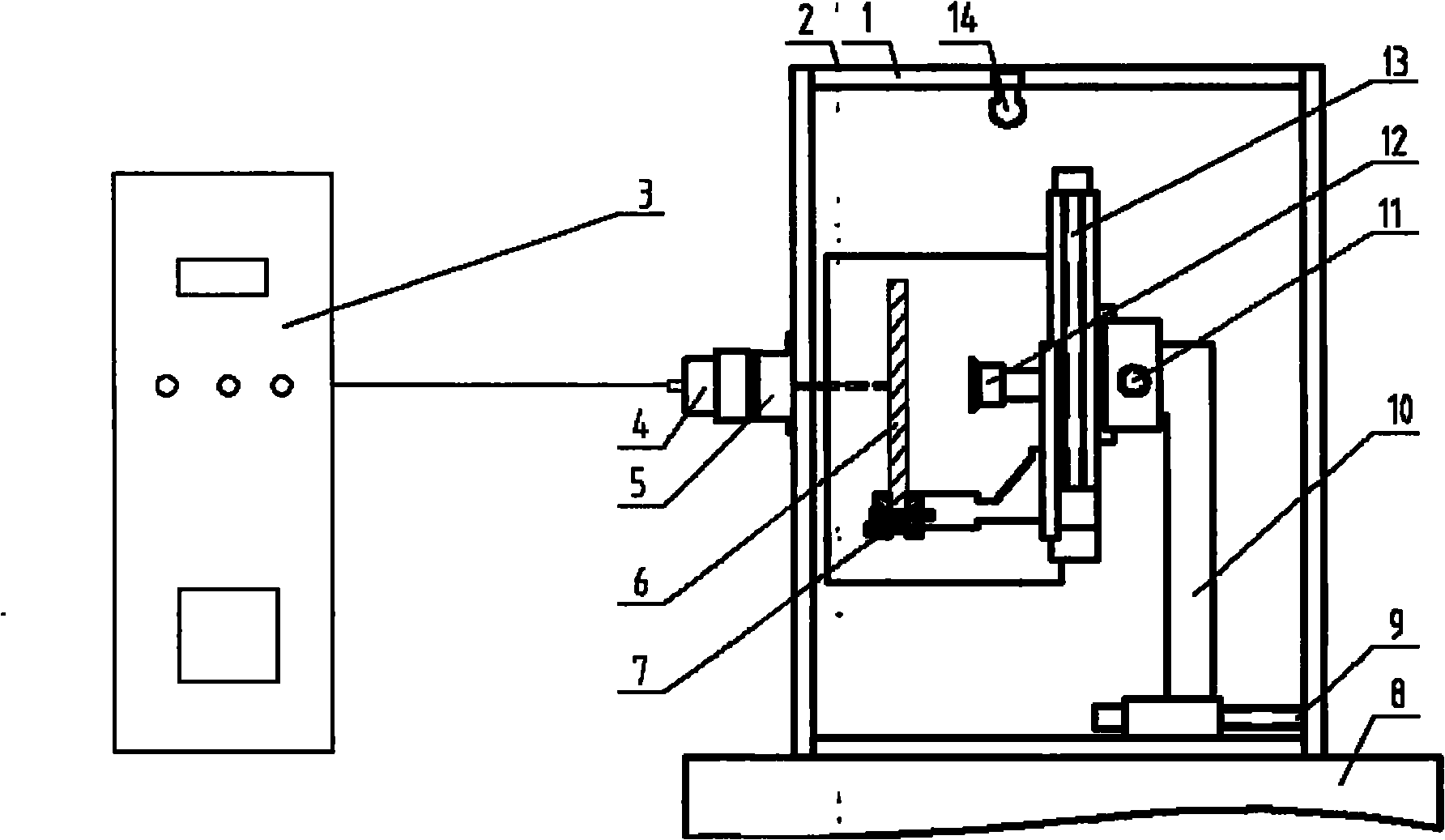

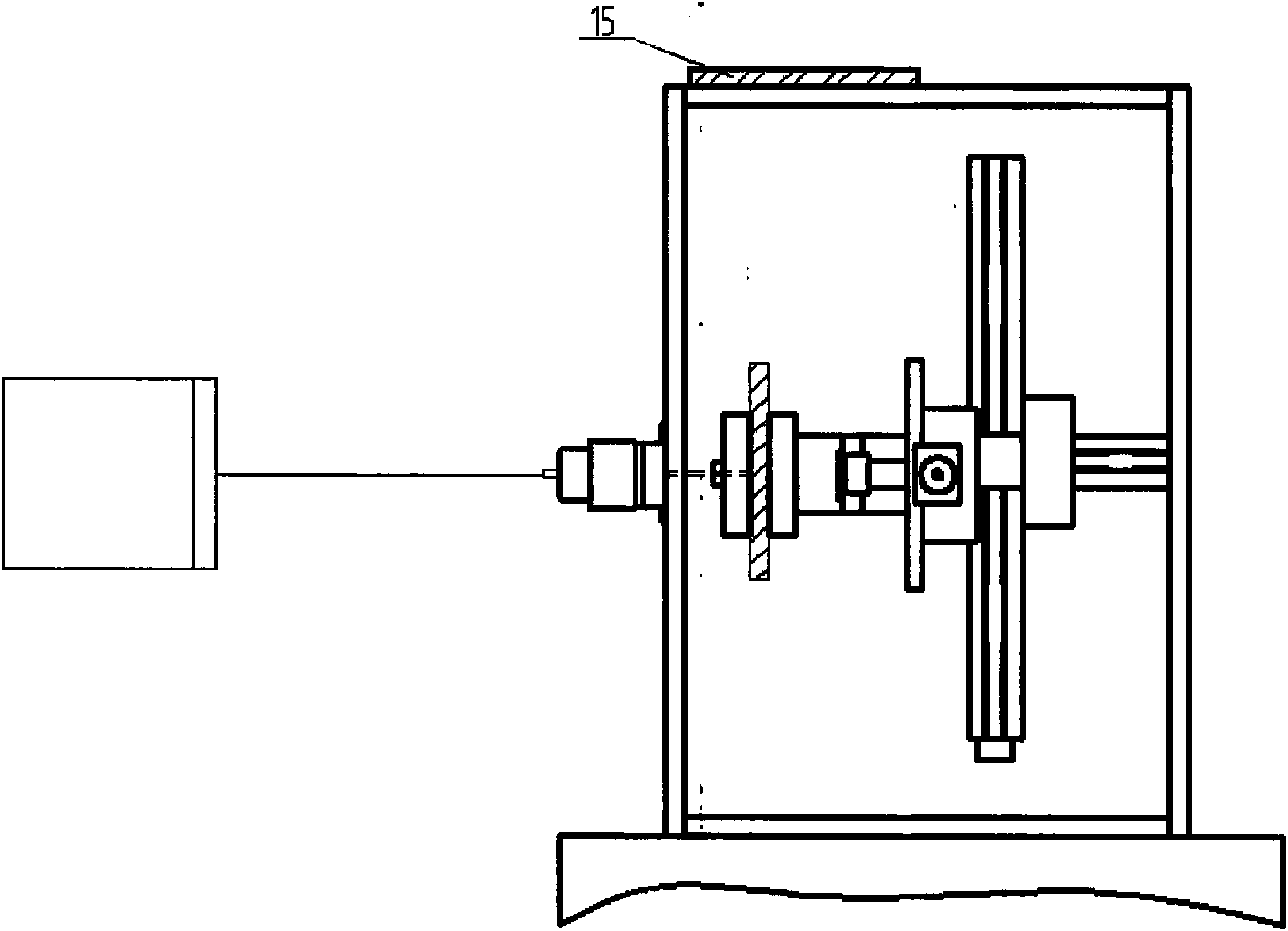

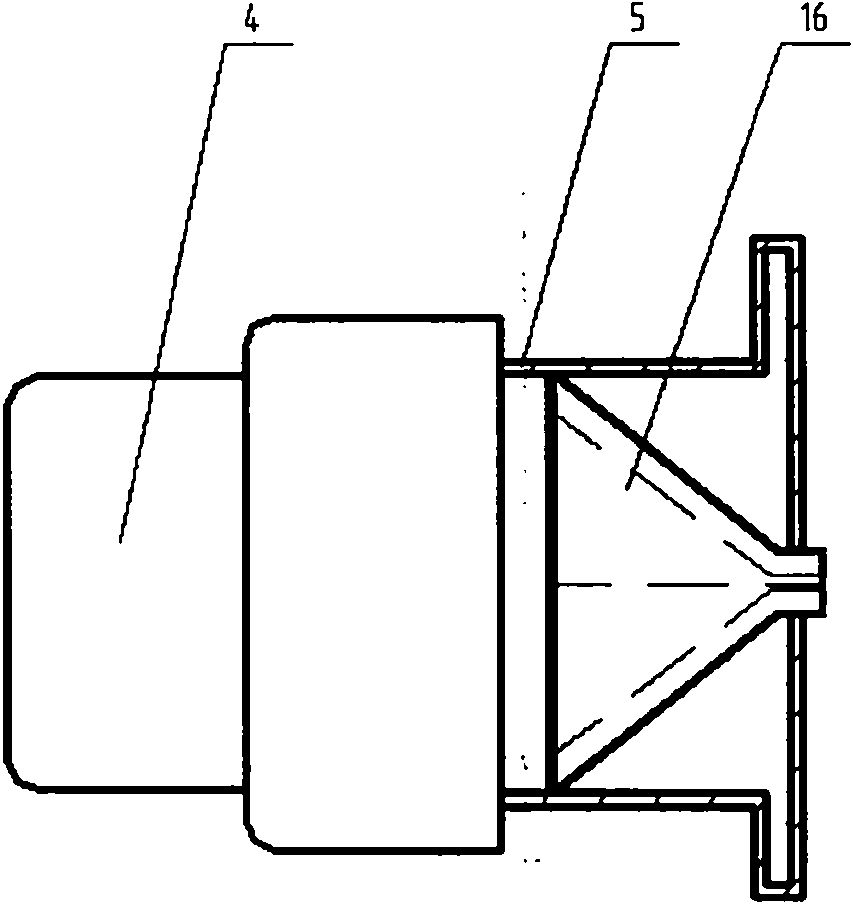

[0034] The present invention is suitable for cutting and processing brittle materials at room temperature. The processing device for microwave cutting brittle materials in the figure mainly includes a magnetron and its processing positioning observation optical system 4, a tapered waveguide mode converter for focusing microwaves, and a changing Magnetron power change system for microwave output power 3. Clamp body for maintaining the material to be processed 7. X-axis guide rail 9 for brittle materials to achieve predetermined trajectory movement, Y-axis guide rail 11, Z-axis guide rail 13, workbench 10, pair The microwave emitting device for local heating of the brittle material 6 clamped by the clamp body 7, the protective plate 1 for shielding microwave radiation, the lighting equipment 14 inside the processing device, and the thermal imager 12 for detecting the temperature field of the heated material.

[0035] The protective plate 1 is connected to the angle iron frame 1 b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com