Method for preparing honeycomb-like active carbon through foaming polyurethane

A technology of honeycomb activated carbon and polyurethane, applied in chemical instruments and methods, alkali metal oxides/hydroxides, inorganic chemistry, etc., can solve the problems of limited application fields and low utilization rate, achieve good adsorption effect and improve utilization rate, the effect of improving the effective utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

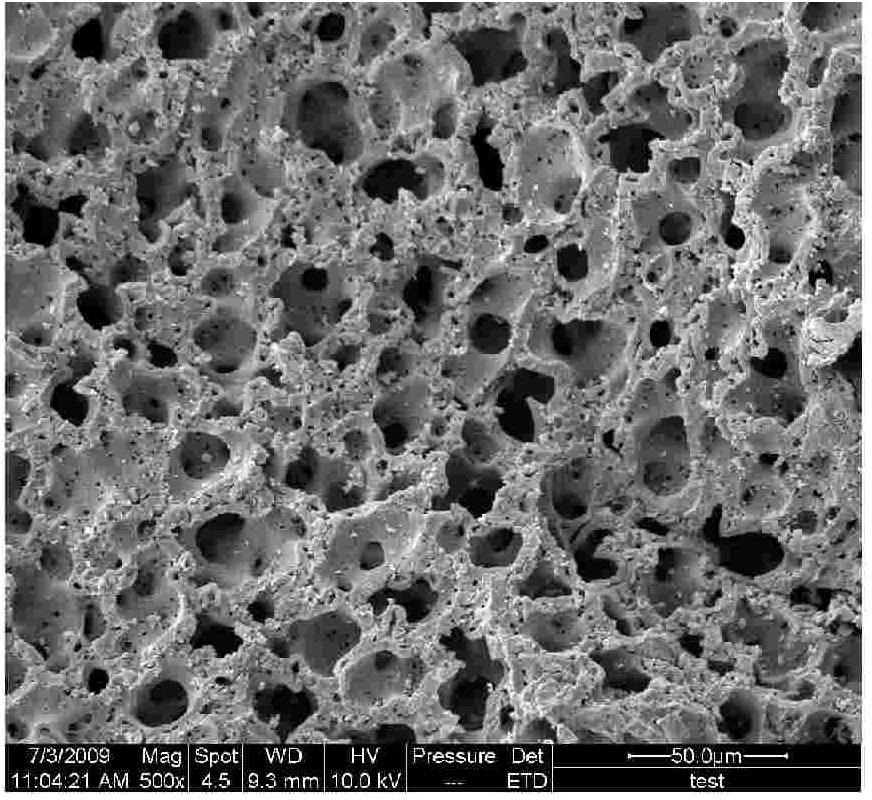

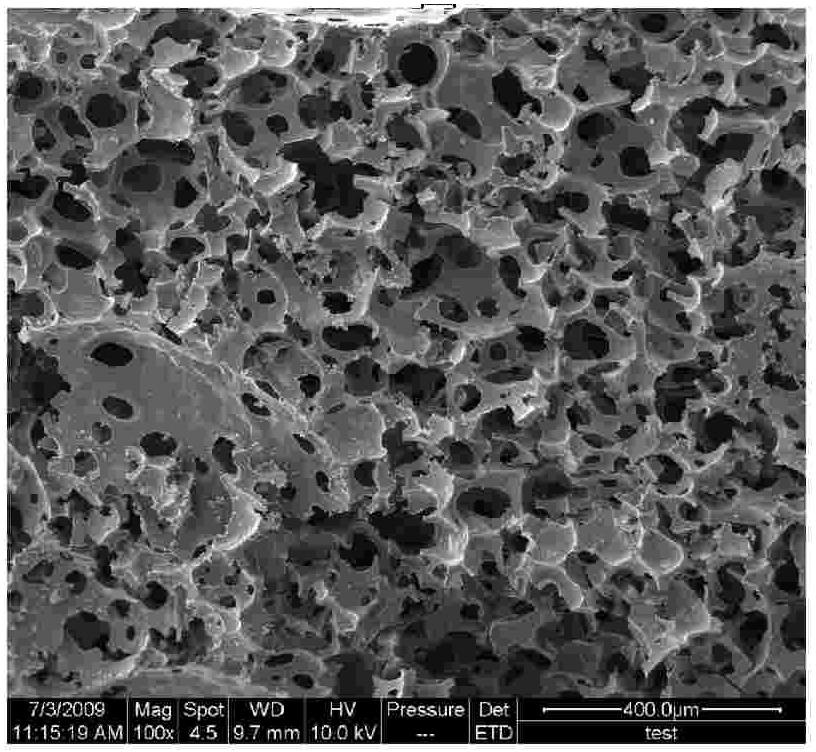

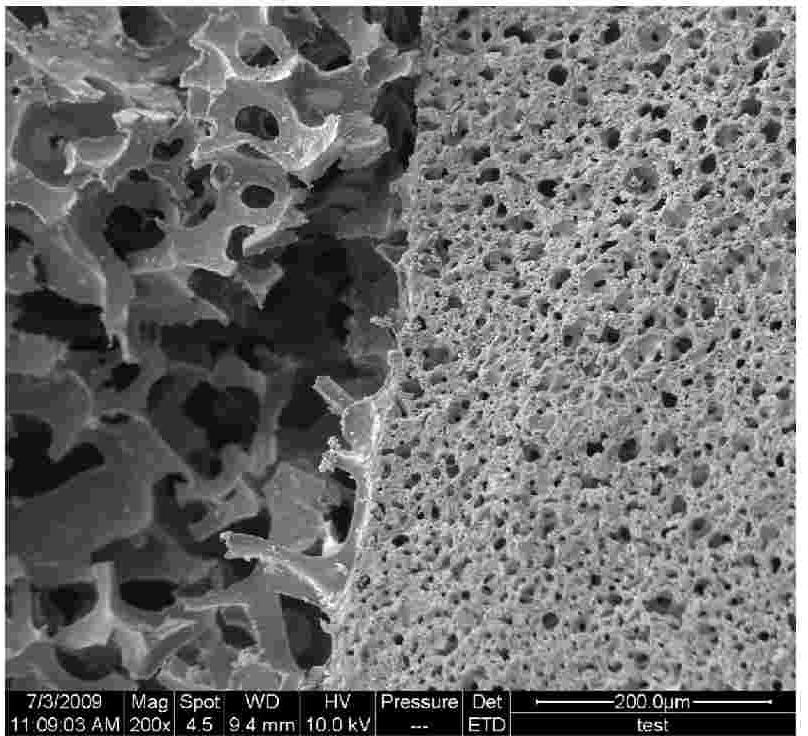

Image

Examples

specific Embodiment approach 1

[0008] Specific Embodiment 1: The preparation method of honeycomb activated carbon in this embodiment is carried out according to the following steps: 1. Weigh 5 to 6 parts of polyether, 0.1 to 0.2 parts of hard foam silicone oil, and 0.08 to 0.09 parts of water according to the ratio of parts by weight , 0.005-0.009 parts of pentamethyldiethylenetriamine, 3.5-4.5 parts of dichlorofluoroethane, 0.12-0.2 parts of cycloethylamine, 0.24-0.3 parts of oil with a concentration of 4.5-5.5 g / L Sodium acid solution, 10 to 11 parts of coconut shell charcoal with a particle size of 8 to 12 meshes and 9.5 to 11 parts of isocyanate; 2. The polyether, hard foam silicone oil, water, pentamethyldiethylene three Mix amine, dichlorofluoroethane and cycloethylamine in the mold to obtain mixture A; 3. Add the sodium oleate solution weighed in step 1 to mixture A and mix uniformly to obtain mixture B; 4. Add to mixture B The coconut shell charcoal weighed in step 1 is stirred at a speed of 500-600...

specific Embodiment approach 2

[0013] Specific embodiment 2: The difference between this embodiment and specific embodiment 1 is that in step 1, 5.2 to 5.8 parts of polyether, 0.12 to 0.18 parts of hard foam silicone oil, and 0.082 to 0.088 parts of water are weighed according to the ratio of parts by weight. , 0.006-0.008 parts of pentamethyldiethylenetriamine, 3.8-4.2 parts of dichlorofluoroethane, 0.14-0.18 parts of cycloethylamine, 0.26-0.28 parts of oil with a concentration of 4.8-5.2 g / L Sodium acid solution, 10.2-10.8 parts of coconut shell charcoal with a particle size of 9-11 meshes and 9.8-10.5 parts of isocyanate. Other steps and parameters are the same as those in Embodiment 1.

specific Embodiment approach 3

[0014] Specific embodiment three: the difference between this embodiment and specific embodiment one is: in step one, weigh 5.6 parts of polyether, 0.16 parts of hard foam silicone oil, 0.088 parts of water, and 0.007 parts of pentagram Diethylenetriamine, 4 parts of dichlorofluoroethane, 0.16 parts of cycloethylamine, 0.27 parts of sodium oleate solution with a concentration of 5g / L, 10.5 parts of coconut shell charcoal with a particle size of 10 mesh and 10.78 parts of isocyanate. Other steps and parameters are the same as those in Embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com