Carbon-nanotube-containing polymer nanocomposite and preparation method thereof

A nanocomposite material and carbon nanotube technology, which is applied in the field of polymer technology and nanocomposite materials, can solve the problems of destroying the conjugated structure, the performance of composite materials, and the dispersibility of carbon nanotubes, etc., and achieves high efficiency and few steps. , the effect of excellent physical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

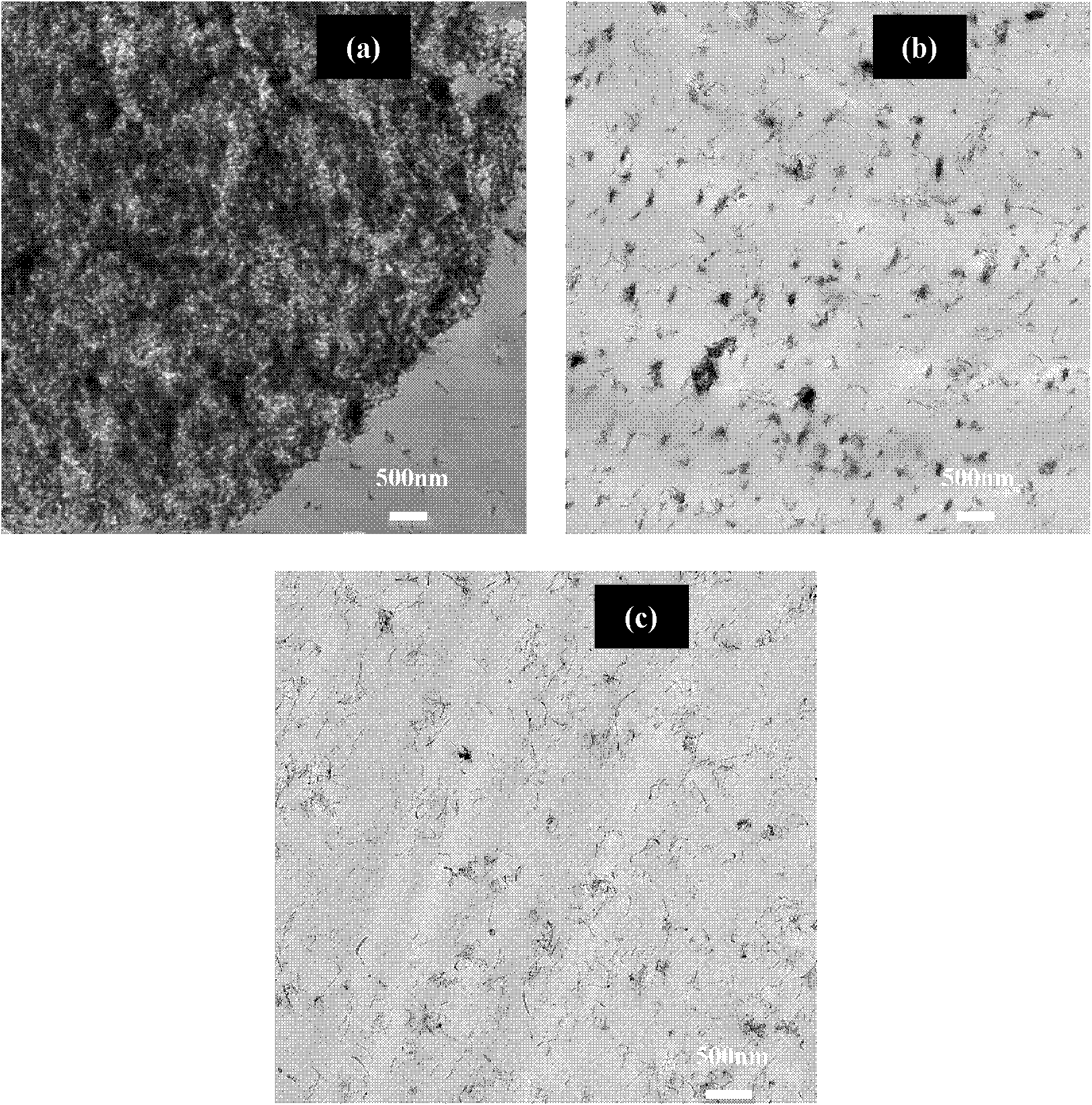

[0046] Weigh 1 g of multi-walled carbon nanotubes (Showa Denko VGCF), 1 g of 1-butyl-3-methylimidazolium hexafluorophosphate, mix them directly and manually grind them with an agate mortar for 5 min to obtain a black gel. Using Raman spectrum analysis, compared with pure carbon nanotubes, the peak position of coated carbon nanotubes is obviously red-shifted, indicating that the interaction between carbon nanotubes becomes smaller and the entanglement becomes less.

[0047] Add 2 grams of carbon nanotubes treated with the above-mentioned ionic liquid and 50 grams of polymethyl methacrylate into the internal mixer. The temperature of the internal mixer is 180° C., the screw speed is set at 100 rpm, and the material is discharged after internal mixing for 5 minutes.

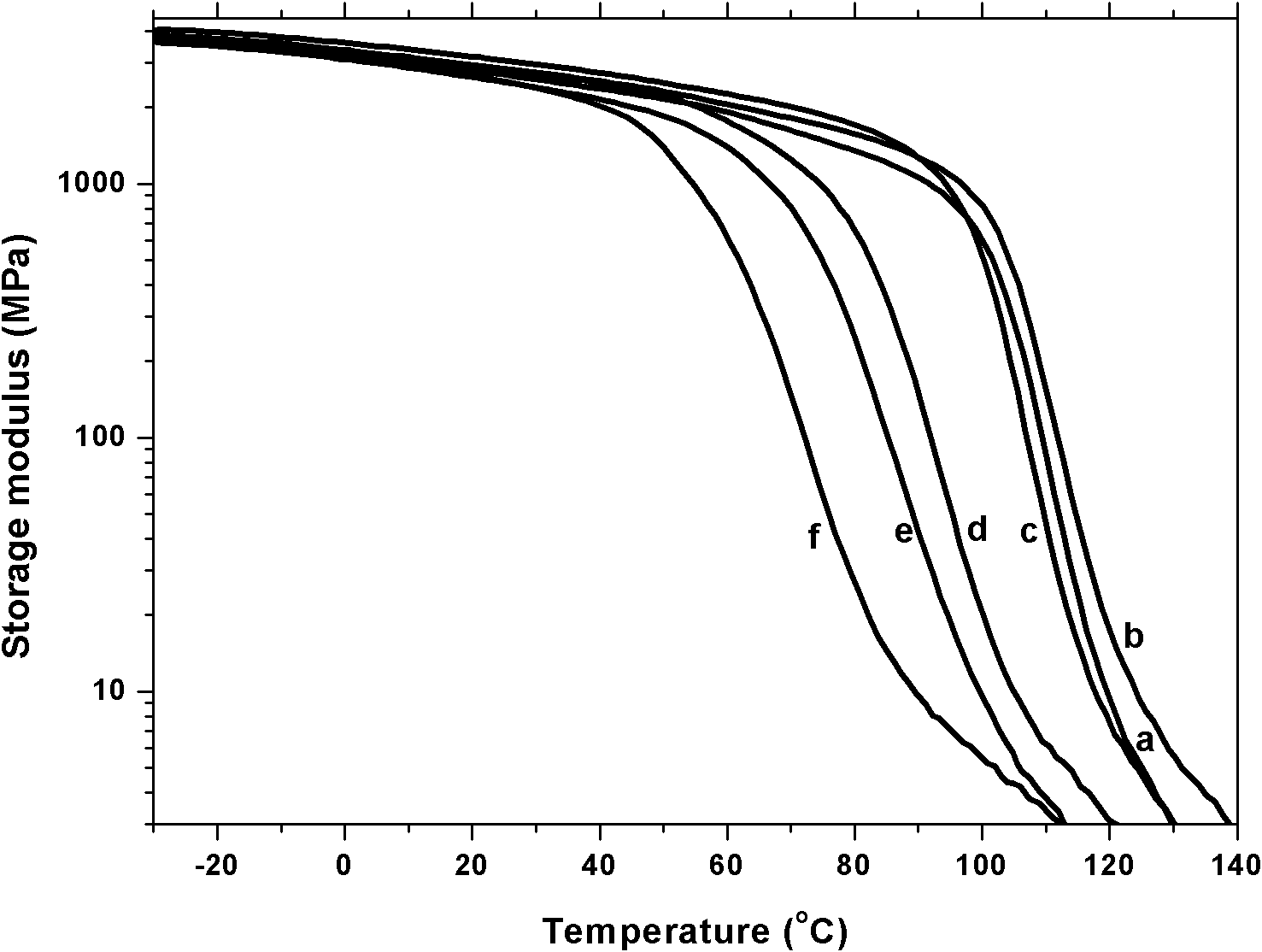

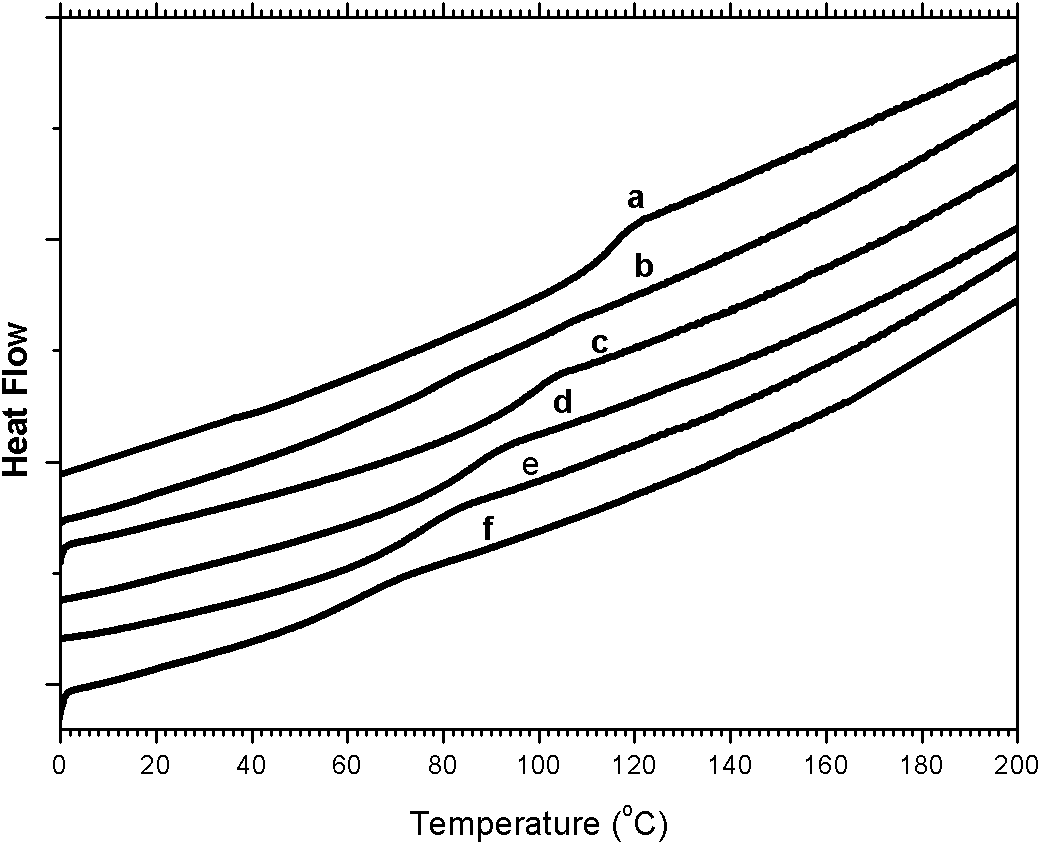

[0048] The above-mentioned kneaded sample was hot-pressed into a sheet with a thickness of 1 mm in a hot press at 180° C., which was recorded as PMMA / IL-MWNTs (IL:MWNTs=1:1), and various tests were performed. The surf...

Embodiment 2

[0055] Weigh 1 g of multi-walled carbon nanotubes (Showa Denko VGCF), 2 g of 1-butyl-3-methylimidazolium hexafluorophosphate, mix them directly and manually grind them with an agate mortar for 5 min to obtain a black gel. Using Raman spectrum analysis, compared with pure carbon nanotubes, the peak position of coated carbon nanotubes is obviously red-shifted, indicating that the interaction between carbon nanotubes becomes smaller and the entanglement becomes less.

[0056] Add 3 grams of carbon nanotubes treated with the above ionic liquid and 50 grams of polymethyl methacrylate into the internal mixer. The temperature of the internal mixer is 180° C., the screw speed is set at 100 rpm, and the material is discharged after internal mixing for 5 minutes.

[0057] The above-mentioned kneaded sample was hot-pressed into a sheet with a thickness of 1 mm in a hot press at 180° C., which was recorded as PMMA / IL-MWNTs (IL:MWNTs=2:1), and various tests were performed. The surface of t...

Embodiment 3

[0063] Weigh 1 g of multi-walled carbon nanotubes (Showa Denko VGCF), 5 g of 1-butyl-3-methylimidazolium tetrafluorophosphate, mix them directly and manually grind them with an agate mortar for 5 min to obtain a black gel. Using Raman spectrum analysis, compared with pure carbon nanotubes, the peak position of coated carbon nanotubes is obviously red-shifted, indicating that the interaction between carbon nanotubes becomes smaller and the entanglement becomes less.

[0064] 6 grams of carbon nanotubes and 50 grams of polymethyl methacrylate treated with the above-mentioned ionic liquid were added into the internal mixer, the temperature of the internal mixer was 180° C., the screw speed was set at 100 rpm, and the material was discharged after internal mixing for 5 minutes.

[0065] The above-mentioned kneaded sample was hot-pressed into a sheet with a thickness of 1 mm in a hot press at 180° C., which was recorded as PMMA / IL-MWNTs (IL:MWNTs=5:1), and various tests were perform...

PUM

| Property | Measurement | Unit |

|---|---|---|

| storage modulus | aaaaa | aaaaa |

| storage modulus | aaaaa | aaaaa |

| storage modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com