Method for measuring ethoxy content of ethyl cellulose by using headspace gas chromatography

A headspace gas chromatography and ethyl cellulose technology, applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve the problems of inaccurate manual extraction, corrosion, and easy to cause errors, etc., to improve sensitivity and repeatability, analyze Short time, high accuracy results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] 1. detection method of the present invention is specifically as follows:

[0031] (1) Solution preparation

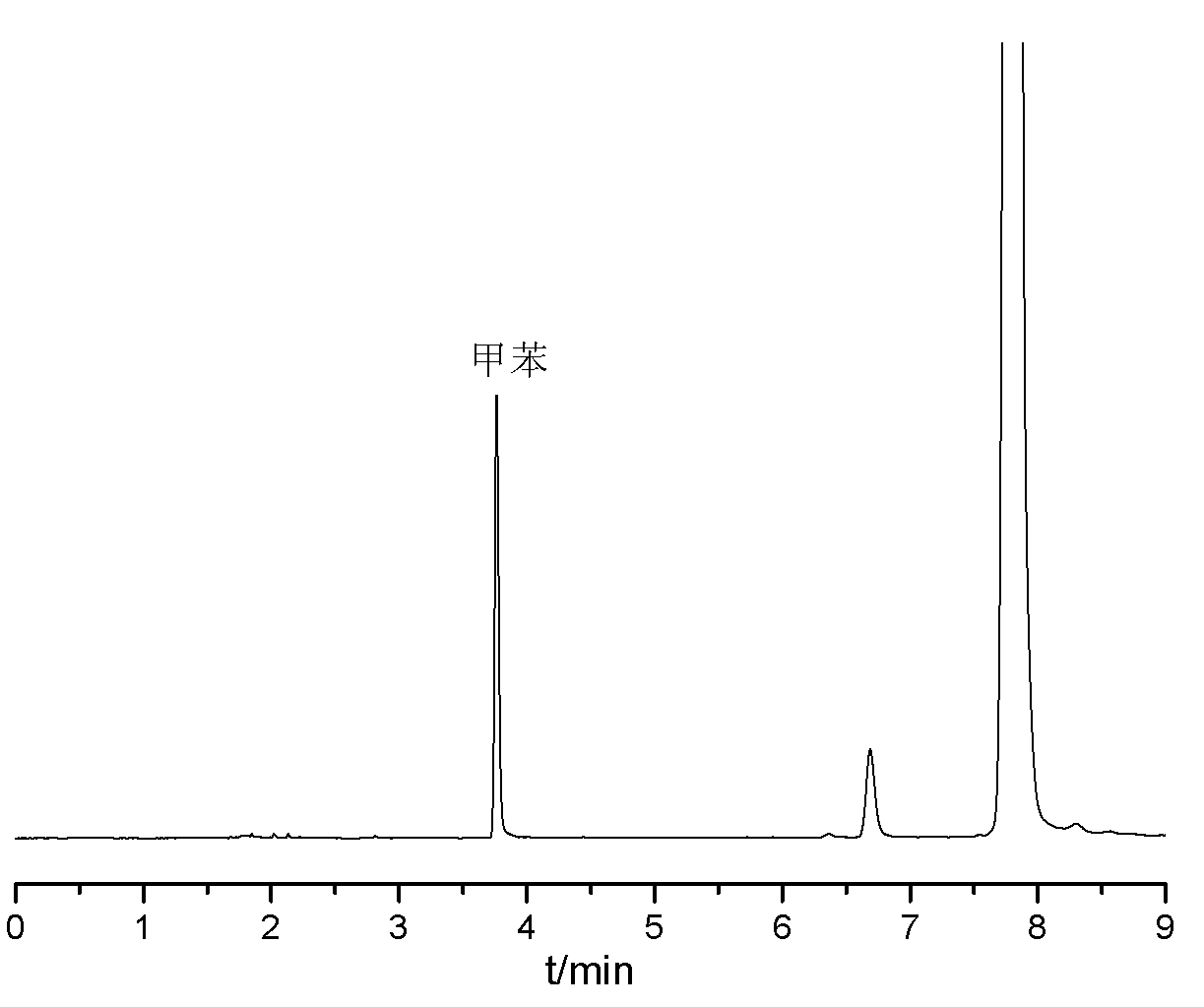

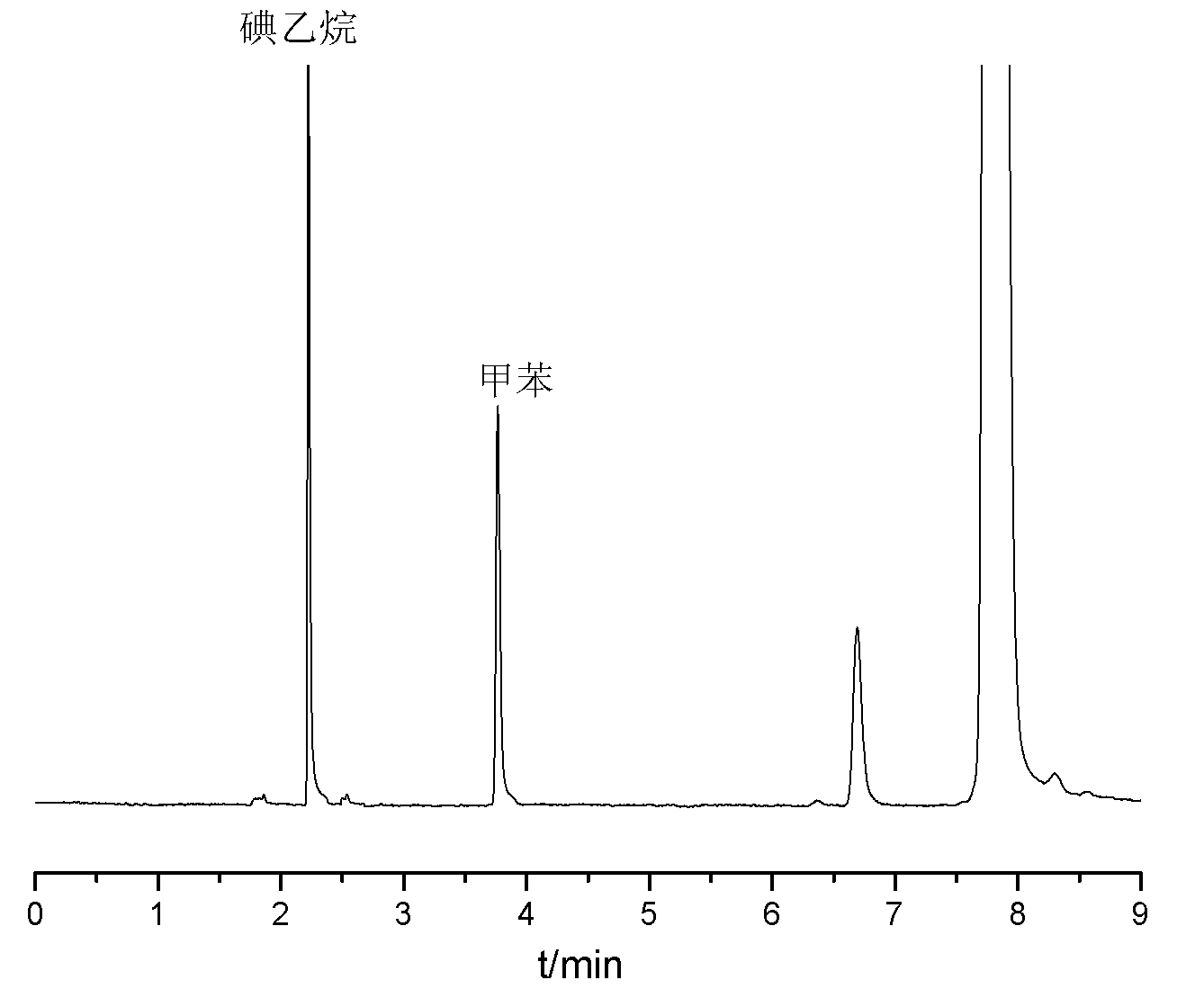

[0032] Internal standard solution: add 10mL o-xylene to a 100mL volumetric flask, then add 2.5g toluene, and finally dilute to 100mL with o-xylene.

[0033] Standard sample solution: Add 20 mg of adipic acid, 15 mg of cotton linters, 1 mL of internal standard solution, 0.5 mL of 8mol / L NaoH solution, and 0.5 mL of 57% HI solution into the headspace bottle, and seal it. Add 2, 4, 6, 8, 10, 15, and 20 μL of iodoethane to the microsyringe puncture, accurately weigh, record the exact mass of iodoethane added, and sample numbers are 1, 2, 3, 4, 5, 6, 7.

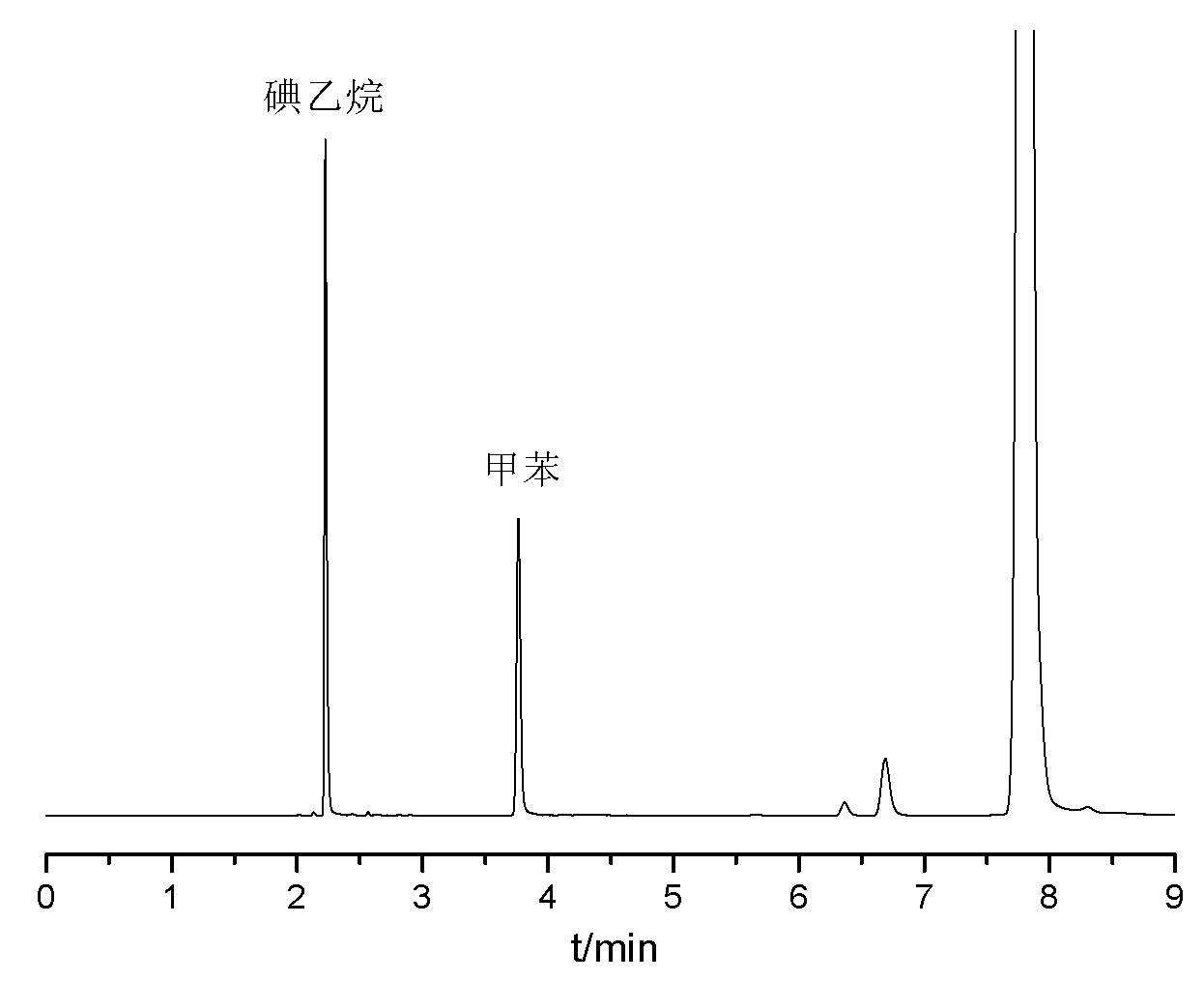

[0034] Sample solution: Add 20 mg of adipic acid, 10 mg of ethyl cellulose (DOW Chemical Company, USA), 1 mL of internal standard solution, and 0.5 mL of 57% HI solution into the headspace vial, and seal it. Weigh the headspace vial and shake the sample for 30 s. The headspace bottle was placed in an incubator at...

Embodiment 2

[0050]Accurately weigh 10 mg of pharmaceutical grade ethyl cellulose sample (Shandong Heda Co., Ltd. batch number 100518003), 5 parts in total, add 20 mg of adipic acid, 1 mL of internal standard solution, and 0.5 mL of 57% HI solution into a headspace vial, and seal it. Weigh the headspace vial and shake the sample for 30 s. The headspace bottle was placed in an incubator at 140°C for 2 h, and the sample was shaken for 30 s every 30 min. Cool to room temperature, weigh again, and make sure there is no leakage. Add 0.5mL of 8mol / L NaOH solution by syringe puncture to neutralize the remaining HI. The results are shown in Table 3. Other steps of this embodiment are the same as in Embodiment 1.

[0051] The above operation was repeated once, and the results obtained are shown in Table 3.

Embodiment 3

[0053] Accurately weigh 10 mg of industrial-grade ethylcellulose sample (Shantai Cellulose Co., Ltd.), 5 parts in total, add 20 mg of adipic acid, 1 mL of internal standard solution, and 0.5 mL of 57% HI solution into a headspace vial, and seal it. Weigh the headspace vial and shake the sample for 30 s. The headspace bottle was placed in an incubator at 140°C for 2 h, and the sample was shaken for 30 s every 30 min. Cool to room temperature, weigh again, and make sure there is no leakage. Puncture the syringe and add 0.5 mL of 8mol / L NaOH solution to neutralize the remaining HI. The results are shown in Table 3. Other steps of this embodiment are the same as in Embodiment 1.

[0054] The above operation was repeated once, and the results obtained are shown in Table 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com